Products Center

Tel:+86-769-82261696

Meijun Sandblasting EquipmentThermosetting Plastic Burr Processing Sandblasting Machine span>It is an automatic machine specially designed for the burr cleaning of thermosetting plastics, bakelite and resin products such as compression and injection molding.

Burr processing sand blasting machine-Shot blasting machine

Details

Burr treatment sandblasting machine,burr machine, endless belt sandblasting machine, burr sandblasting machine, burr polishing machine, burr shot blasting machine

Features:

1. The dust collector is hidden in the body.

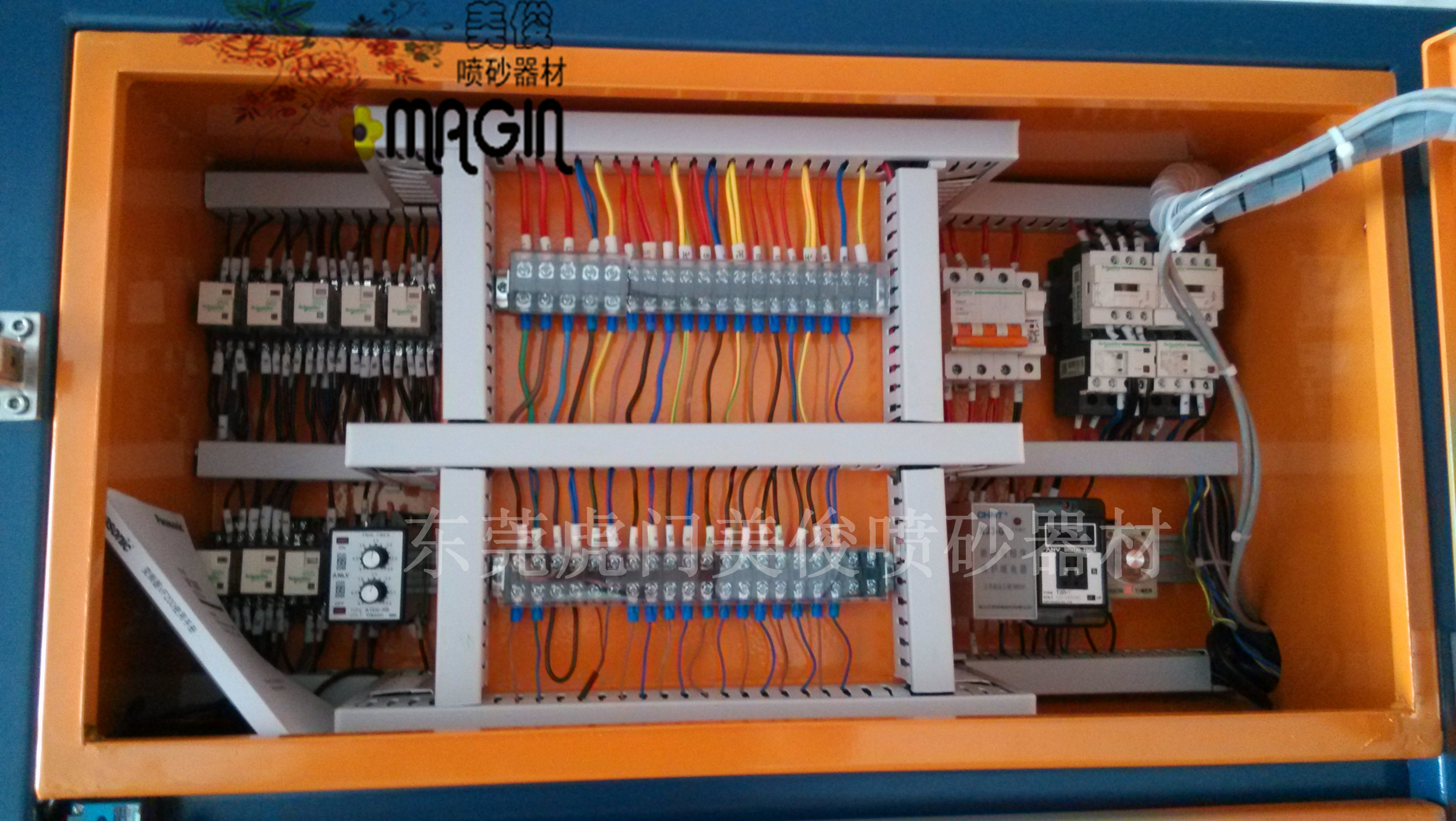

The input port and the operation panel are well arranged, easy to operate and simple to maintain.

2.The projecting material is ejected by the high-speed rotating impeller, the radiation area is large, the projectiles are dense, the surface of the product, the inner hole, the concave part, and the burr of the difficult part can be cleaned in a short time., Its high-efficiency cleaning ability.

3. After the products are processed by this machine, they are all beautiful and shiny. (Because this machine is equipped with automatic humidification and automatic blowing device to remove dust)

4. This machine can be used continuously for a long time without replacing parts, so the maintenance cost is very low, and it can be processed in large quantities. Each machine can reach the production capacity of 10~15 people, which is to reduce costs and reduce labor. best weapon.

This machine is used to process the surface burrs of compression or injection molding thermosetting plastic products.

Abrasive ejection is a self-contained projection device, which integrates a chassis, an endless belt conveyor, and a dust collector.

The projecting material (plastic pellets) is projected on the product through the high-speed rotating impeller, and the burrs in the form of flakes and the burrs in the recesses or holes can be removed in a short time. The size of the projected force can be adjusted to the appropriate number of revolutions on the inverter keyboard on the control panel.

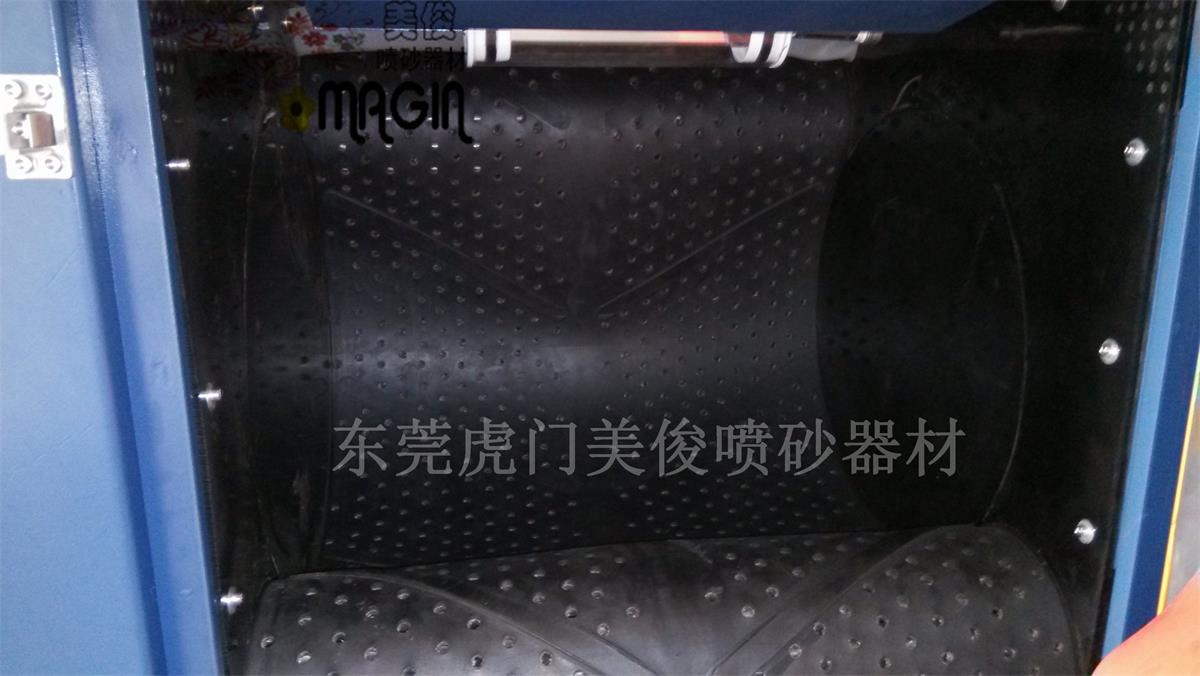

The spraying room is composed of a belt conveyor, and the rubber is all laid in the room. The input product is uniformly removed by the impact of the projection material thrown out at a high speed while the endless belt is rotating and stirring.

The projected material can be used continuously through the sophisticated circulation system. The powdery burrs and the smaller projection materials are attracted and collected by the dust collector, while the larger burrs are filtered out by the screen.

In the middle of the suction pipe, there is a nozzle for humidification. Appropriate amount of moisture can enhance the spray cleaning effect, prevent dust adhesion, and increase the life of the projection material.

Operation Notes:

1. The processing time of the product varies according to the processing volume, shape and projection material. The adjustment method is that the impeller rotation speed is between 45~60HZ (2250~3600R.PM). To the best projection time, generally about eight minutes.

2. Each wear-resistant rubber is flammable (the ignition point is about 300. C), please keep away from fireworks.

3. Before starting the operation, please confirm whether each door is completely closed, especially the operation door should not be opened during the blasting operation.

4. During operation, the projection material will be slowly consumed, and the projection amount of the impeller will gradually decrease. It should be checked at the front door inspection window from time to time, or the current value of the projection ammeter can be compared. If it decreases, please add an appropriate amount.

5. If there is abnormal sound during operation or the bearing or motor is overheated, it should be stopped immediately for inspection, and the power should be turned off to ensure safety during maintenance.

6. Before the operation starts or after the operation, check the condition of each part. If there is any wear and tear, please repair and replace it immediately.

7. The amount of water in the humidification bucket should be checked every day, and if it is insufficient, please add an appropriate amount.

8. After daily operation, please stop and shake the left handle of the case a few times to shake off the dust in the dust pipe.

9. After daily operation, please clean up debris and dust.

10. If the rubber band is offset or slipped, please slightly adjust the adjustment screws on both sides of the chassis.

11. Before spraying the product, please screen it, and take out the ejector rod and other sundries, and then put it into spraying, so as not to scratch the belt and prolong the life of the belt.

12. The endless belt conveyor has a safety pin device. If the endless belt is stuck, the safety pin will be automatically cut off, and the endless belt will stop rotating immediately without damaging the machine. Please take out the stuck item, then remove the chain cover and replace it. New safety tip.

13. Chains, bearings, please add grease 2 times a month.

14. After the sponge sliver of the door is worn out, please replace it with a new one.

15. If the nozzle for static elimination is blocked, please use a bristle brush, bamboo stick and plastic needle to clean it, and do not use a metal through needle.

16. After use, please turn off the main switch.

Once the machine is set up, please prepare as follows:

1. Connect to mains power. (Please follow the wiring shown in the P11 power supply wiring diagram)

2. Connect compressed air source. (Nozzle blowing pressure is within 0.5kg/cm2)

3. Prepare a bucket and add clean water or antistatic fluid.

4. Take out the cover from the lower door on the front and put in the projection material. (Standard input is 10kg)

5. Timer for setting humidification time T4 (depending on the size of the nozzle aperture, including ∮1.1mm, ∮0.71mm, ∮0.51mmThree:

Large aperture∮1.1mm,on1seconds off15seconds.

Aperture ∮0.71mm,on1seconds off12seconds,

Small aperture ∮0.51mm,on1seconds off 10seconds)

6. Set the timer T3 for the projection time (set reference to 8 minutes).

7. Set the timer T5 for the end-of-alarm waiting time (setting reference is 2 minutes).

8. Set the timer TR to end the alarm time (set reference to 1 seconds).

9. Start each drive part, and confirm the rotation direction of the motor (just make sure that the belt is rotating in the forward direction).

Confirmation method: Press the belt forward switch, and the belt should rotate to the inside of the machine. Otherwise, connect the R. S. T. The positions of any two of the three lines can be reversed with each other.

After the above work is completed, please follow the operation precautions and operation sequence on the next page to start.

Note: 1. The mechanical setting must consider the operation space and maintenance space.

2. If spray-washing products with special materials, such as bakelite powder with fiber, urea, engineering plastics and other products. Because it is easy to generate static electricity, please use antistatic liquid, which can eliminate static electricity and make the surface of the product cleaner and more beautiful.

The company adheres to the corporate philosophy of "leading technology, prospering the factory with quality", and takes "integrity and truth-seeking" as the foundation of operation, and provides you with high-quality products and excellent services.

Non-standard models of machines can be customized according to customer needs! ! !