Products Center

Tel:+86-769-82261696

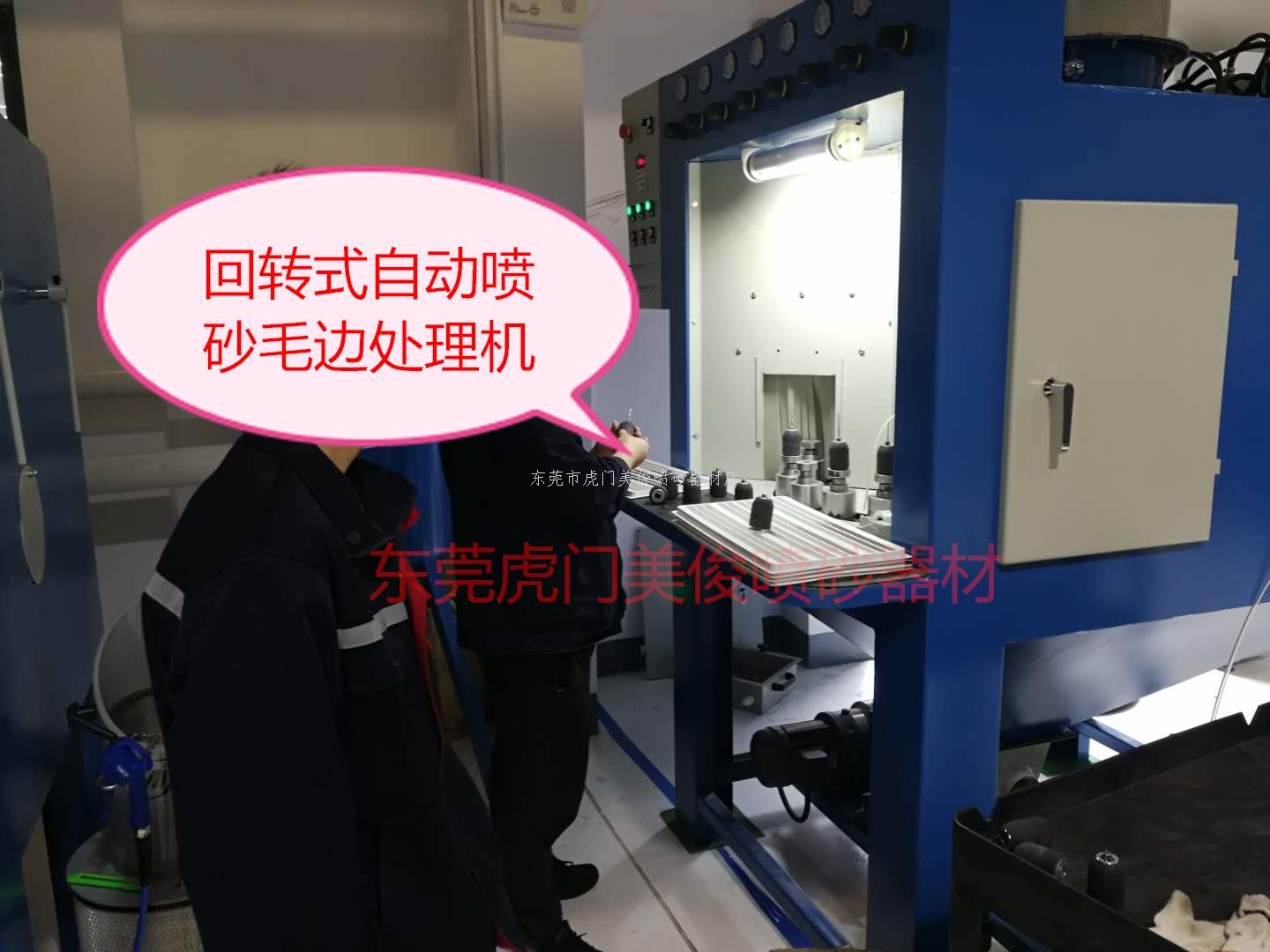

1.Equipment name: Cyclone rotary closed automatic sandblasting machine Rotary burr blasting machine

2.Model: MAGIN-1200SA-18Z-6A

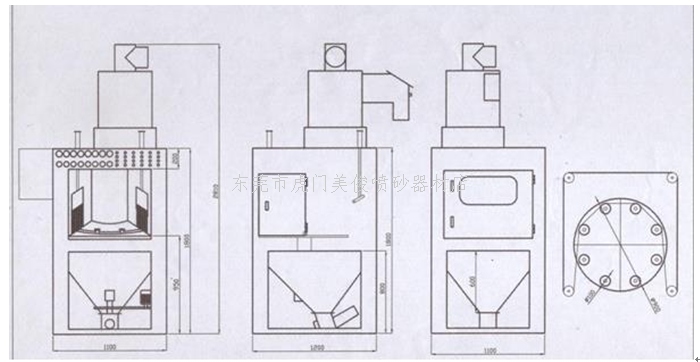

Machine size: 1200mm*1100mm*1800mm high (excluding cyclone separator 700mm)

Auxiliary machine (dust collector) size: 1200 mm * 1200 mm * 2000 mm (excluding fan 400mm)

Diameter of rotary turntable: 700mm 18 stations, 2 sets of fixtures

3.Equipment use: Cylinder, tube, bar, round, square, conical workpiece surface deburring, rust removal, surface passivation, sandblasting of the same color .

4. Main components:

1) Body structure 2) Sandblasting system 3 Air source treatment system 4) Cyclone separation system (including dust removal system) 5) Lifting system 6) Turntable system 7) Electronic control system

V.Machine Features:>

1)The machine feeds the material in the front cabin, and blasts the rear cabin. The front door exits the cabin after one rotation. It is easy to enter and exit the material, the operation is simple and easy to learn, and the maintenance is convenient. The rear cabin is a closed sandblasting cabin;

2)Workpiece placement and retrieval method: This machine is the manual placement and retrieval method of the main door open;

3)The sand is automatically recycled, and the cyclone can effectively separate the dust;

4)The sand material has good uniformity, which is conducive to the stability of processing quality;

5)The turntable rotates automatically;

6)The sandblasting gun swings up and down from multiple angles for sandblasting.

>

>

Six.Scope of application and sand material

This machine is a cyclone rotary closed automatic sandblasting machine, which is independently designed according to the shape and characteristics of the product;

The applicable sand materials are: walnut sand, resin sand, brown corundum, glass beads, white corundum, etc.

7.Equipment capacity and related parameters

1) Capacity: depending on the material, size and blasting requirements of the blasting product, the speed is adjustable;

2) Air source requirements: within 8KG flow rate is 3-4m 3/min

3)Air consumption: about 3-4m 3/min

4) Power requirements: three-phase five-wire (that is, three-phase 380V, one neutral wire and one ground wire) power loss is 4-6 KW/H

Seven machine structure (with photo)

1.The body structure is welded by 3mm steel plate, and the inner and outer surfaces are painted, and the color is blue and white standard color.

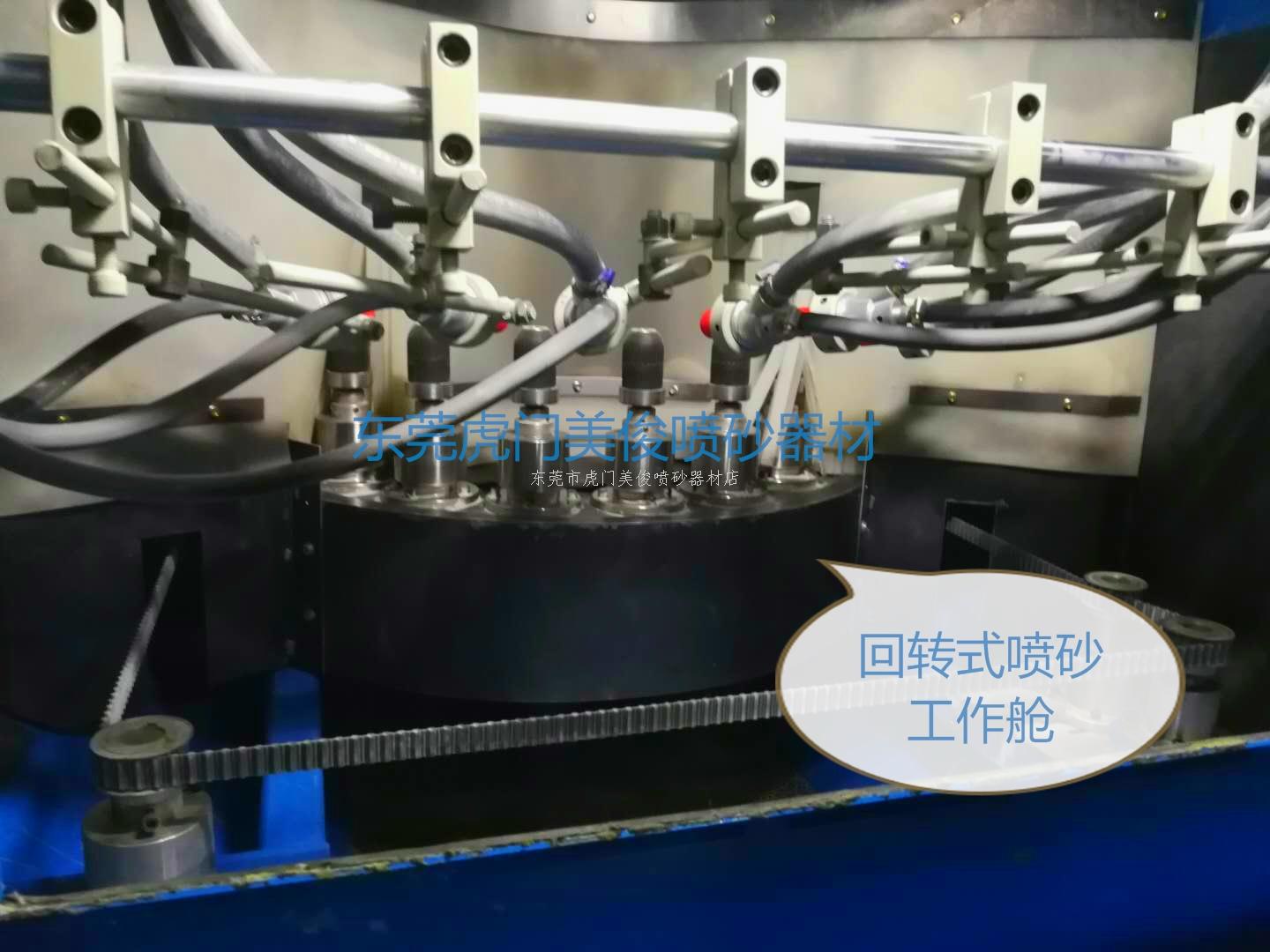

2.The sand blasting system is mainly composed of spray guns, nozzles, sand paths, gas paths, etc., 6 aluminum alloy spray guns (equipped with 6 boron carbide nozzles); equipped with high-quality wear-resistant The sand pipe and trachea, the air source pressure is required to be within 8kg, and the sand blasting pressure is set according to the processing requirements of the product; automatic processing method:

3.The air source treatment system is mainly composed of a pressure regulating valve, a pressure gauge, a solenoid valve, etc. When adjusting the air pressure, gently pull out the knob of the pressure regulating valve, turn it in the direction marked "+" to increase the air pressure, and turn it in the direction marked "-" to decrease the air pressure. When adjusting the blasting pressure, it must be adjusted with the spray gun turned on to meet the standard. After adjusting the air pressure, gently reset the knob. The control of the on-off solenoid valve of each gun is controlled by the dial switch on the electric control box.

4.The cyclone separation system is composed of a cyclone separation cylinder and a dust collector; the cyclone separation cylinder adopts a standard separation cylinder, which can effectively separate the sand and dust and make the useful sand recycle. ; Equipped with a 4kw dry dust collector. The air outlet of the cyclone separator is connected with the air suction port of the dust collector through the organ pipe. The sand suction port of the cyclone separator generates a strong suction through the wind of the dust collector, and the sand material is sucked into the cyclone separator. The sand material and dust are rotated and separated along the outer edge of the cyclone separator, and the useful sand material falls into the storage. In the sand tank, the dust is separated into the dust collector. The machine uses the cyclone separator to automatically circulate the sand material. It is also a process of dust removal while circulating and separating.

5.The spray gun swing system consists of swing motor, swing shaft, swing link and so on. The spray distance and spray angle of the spray gun are adjustable.

The up and down swing of the spray gun is driven by the swing motor to drive the swing shaft to run up and down at a constant speed, and the swing link drives the spray gun bracket to run up and down, and the spray gun is fixed on the spray gun bracket. Thereby, it is driven to swing up and down. The swing angle is adjustable, which meets the requirements of uniform sandblasting of different lengths and thicknesses of the blasting part (drill) of the workpiece by the spray gun.

There is one rocking axis; a spray gun bracket is arc-shaped to fix 6 sandblasting guns at regular intervals, and each rotating workpiece passing by is sandblasted and deburred from multiple angles. In this way, driven by the eccentric wheel, the roller connected to the spray gun bracket rotates back and forth at a certain degree, thereby driving the sandblasting gun bracket to swing up and down, thus ensuring the sandblasting stability of different lengths of the drill bit, as long as the spray gun is up and down When the swing angle reaches the length of the blasting section of the drill bit, it can be blasted and cleaned to the part of the drill bit within the swing angle of the spray gun.

7.The turntable system of this machine adopts the method of continuous passing, and is equipped with 18 small turntables that rotate automatically, which are composed of rotating motors, turntables, transmission belts, speed governors, etc. 18 groups of small turntables can transport 18 products at the same time. The turntable is driven by the rotating motor through the transmission belt to rotate at a uniform speed, and the products are then driven to rotate at a uniform speed to the sandblasting chamber. Programmable timed blasting of a single self-rotating drill bit to maintain uniformity.

Adjustable rotation speed: The 18 small turntable workpieces of this machine are hollow, which is convenient for tubular objects of different lengths to be inserted into the turntable, so as to ensure that the exposed drill bits on the turntable are all within the angle of the sandblasting gun swinging up and down. To achieve this To operate, a set of ring fixtures must be provided for each drill bit of different diameter and diameter, and the drill bit must be manually inserted into the ring fixture, so that the exposed drill bit thread part to be sandblasted is on the top of the ring fixture (the one after placing it in the small turntable). The upper part), especially the uniform height, ensure that it is within the angle of the gun swinging up and down.

6.The electronic control system consists of transformers, motors, control components, solenoid valves, etc., and is made in strict accordance with safety standards. The power supply is three-phase five-wire 380V AC (three-phase live wire, one neutral wire and one ground wire)

7.Peripheral equipment configuration: air compressor, dryer (customer-owned or our company supporting)

VIII. Energy consumption

1.Dust collector motor 4KW

2.Station Motor:30-60W

3.Lighting and Control Circuits 200W

4.Swing Motor 0.4KW

5.Rotating motor 0.4KW

Nine, the standard of the main parts of the machine is clear

1. Pressure regulating valve 6

2. Solenoid valve 6

3. Lighting LED lights 1

4. Airbrush 6

5. Nozzle (Boron Carbide) 6 sticks

6. Dust collector 1 set

7. Dust collector 4 inch×800 25 strips (or filter element)

Other accessories, etc.

Equipment

Technical Engineering