Products Center

Tel:+86-769-82261696

Dongguan Meijun Automation Equipment Co., Ltd.

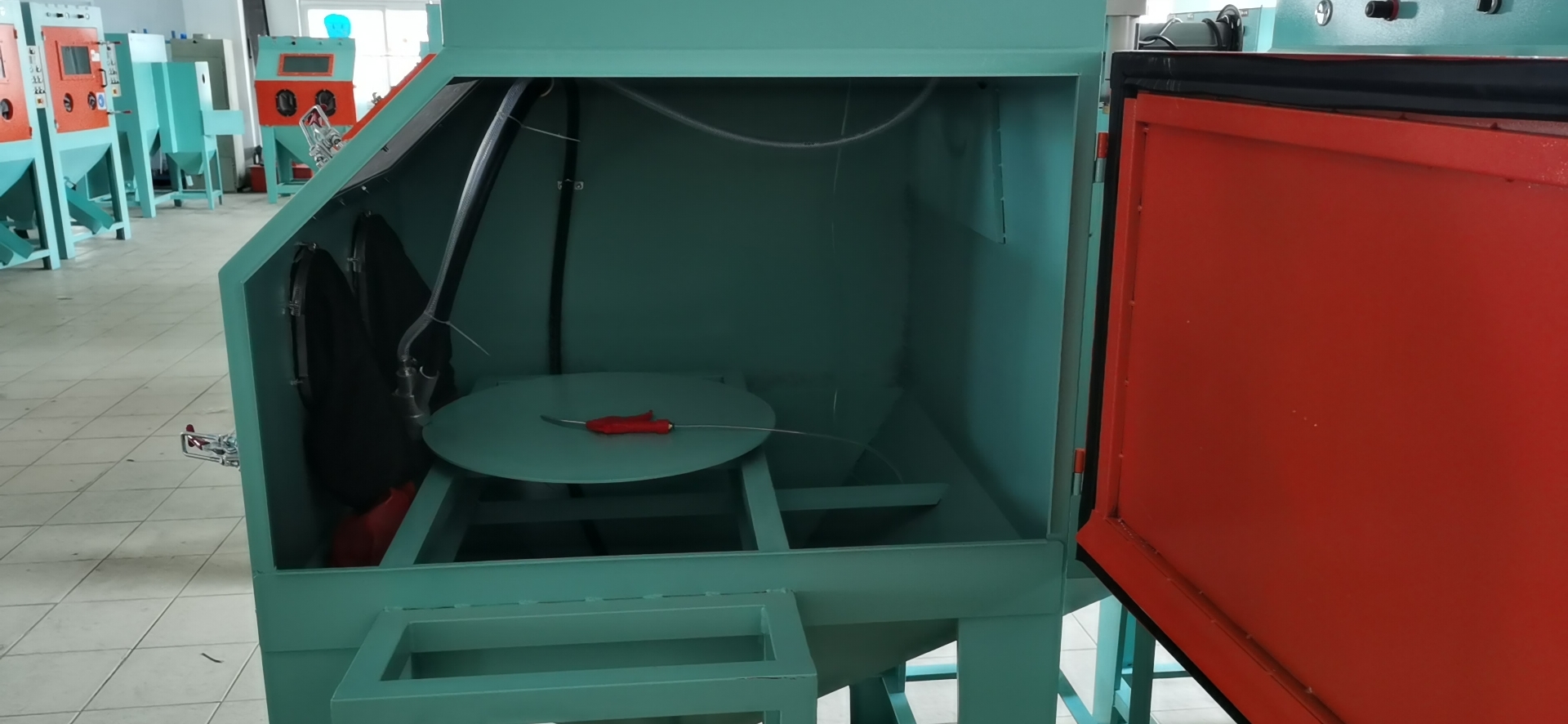

Magin-1010TTrolley turntable handDesign scheme of mobile sandblasting machine

I. Program overview:

The company is a modern enterprise specializing in the research and development, design, manufacture, sales and technical services of surface treatment and related non-standard products. National key enterprises provide surface treatment equipment.

According to the product features provided by customers, this machine is a specially designed dry-type manual cart turntable sandblasting machine, which is used to process the edge surface sandblasting of large-sized special-shaped workpieces, which can remove the workpieces. Surface bonding lines, flow lines and mold marks, etc.; it can meet the process requirements of deburring, oxide skin, surface finishing, electroplating or pretreatment before spraying on the workpiece surface.

This set of equipment is mainly composed of host, dust removal system, electrical system, manual cart, manual turntable, air compressor(User-prepared)composed.

Blast Media:Steel grit, glass beads, brown corundum.

Workpiece blasting requirements:Sandblasted exterior surface.

Processing range: This machine is suitable for spraying on the outer surface of products with length≤980mm, width≤800mm, height≤1000mm, and weight≤250KG Sand treatment.

Processing efficiency: Subject to the worker’s proficiency

Design criteria:

JB/T8355—2008 General technical conditions for sandblasting equipment

GB/T8923-2008 ; Steel surface rust grade and rust removal grade before coating

GB16297-2008 Comprehensive pollutant discharge standards

GB/T5226.1-1996 Industrial Machinery and Electrical Equipment Part 1: General Specifications

GBZ 1-2002 Industrial Hygiene Standards

GB12348-2008 Enterprise Boundary Noise Standards

II. Workflow:

Workers place the product on the cart turntable feeder and manually feed it into the blasting machine.

The processing sequence is as follows:

1. During sandblasting, workers hand-held sandblasting to blast the product.

2. The processed workpiece is then carted from the blasting chamber to the feeding rack,

3. Workers unload the workpiece from the turntable end of the cart.

4. This machine adopts manual processing method.

Third, the features of this machine:

1. The operation is simple and the efficiency is high. The sand with different particle sizes can be replaced according to different process requirements, and the sand can be recycled automatically to save costs.

2. Equipped with a separate bag filter, which can remove the dust generated during work.

Fourth, the main structure of sandblasting machine:(See design plan)

1, host shell:

It is welded with 2.5-4mm cold steel plate, and the surface is painted. There is a filter at the lower part of the engine room to prevent large debris and workpieces from falling into the sand. There is a blowing air gun in the suction chamber to blow off residues on the workpiece. The sandblasting machine is equipped with an observation window, which can observe the entire processing process and handle emergencies at any time.

Sand blasting area size: 1000mm(L)×1000mm(W)×1000mm(H).

Host dimensions: 1000mm(L)×1450mm(W)×2000mm(H)

Manual cart turntable: Ф600mm bearing 250KG

2, unpowered feeder:

The workpiece is transported by manual cart turntable.

3, gun group:

This machine is equipped with 1 spray gun, sandblasting gun model: Magin-B1 B4C. The nozzle material is made of high-quality wear-resistant boron carbide. Nozzle diameter: Ф8mm.

4, blow gun:

This machine is equipped with a manual blow-off gun for blowing off the workpiece and the machine after sandblasting is completed.

5, sand bucket:

Welded by 3mm cold steel plate, the surface is painted. There are 2 layers of filter screen in the sand collecting bucket. It prevents the workpiece or large debris from falling into the material compartment, blocking the spray gun and affecting the normal work.

6, access door:

Welded from 3mm cold steel plate, the surface is painted.

7, electrical system:

1), the electrical system consists of filters, pressure gauges, pressure regulating valves, solenoid valves and corresponding pipelines and control components.

2), the power supply is set to 200V, 50HZ.

8, air compression system (Customer prepared):

The blasting pressure can be adjusted according to the process requirements. The pressure ranges from 1 to 7bar. The spray gun is controlled by a pressure regulating valve and is equipped with a pressure gauge display. The air compressor is required to meet the air pressure of not less than 7bar.

13, energy configuration and consumption:< /p>

1. 1 centrifugal medium pressure fan: The power is about 750-1200W;

2. Lighting and control circuit: power about 200-300w;

3. The total power of the machine: about 1.0-1.6Kw except for the air compressor.

V. List of main wearing parts:

|

Serial |

name Weigh |

rule Grid |

Wood Material |

Preparation Note |

|

1 |

Airbrush |

MG-B1type |

Aluminum alloy |

Lifetime300~600hours |

|

2 |

Nozzle |

Ф8mm |

boron carbide |

Lifetime200~400hours |

|

3 |

Sand Tube |

Ф21mm |

Abrasion Resistant Rubber |

Lifetime600~1200hours |

|

4 |

trachea |

Ф8mm |

Abrasion Resistant Rubber |

Lifetime600~1200hours |

|

5 |

Bag |

Ф110mm |

|

6 months |

|

6 |

Sealant |

Design |

rubber |

indefinite,Uncertain service life |

|

7 |

Window Glass |

Design |

Plain Glass |

indefinite,Uncertain service life |

6. Production cycle, transportation, installation, commissioning and acceptance of equipment:

1. Equipment delivery cycle: Since the contract takes effect (that is, the contract amount is received):

A. 3 days in stock. (Not including the number of national statutory holidays, involving the extension of statutory holidays).

B. Order 15-25 (excluding the number of national statutory holidays, involving the extension of statutory holidays).

2. The supplier shall be responsible for the transportation and expenses of the equipment to the buyer's site. The transportation method: truck. The user must provide free on-site unloading and installation lifting equipment and supporting personnel.

3. Before the installation and commissioning of the equipment, the buyer must confirm that the necessary installation conditions such as water, electricity and temporary residence required by the equipment site are ready, and notify the supplier to send a debugging technician to the buyer’s site. Assist the buyer to complete. At the same time, during the installation and commissioning of the equipment, the buyer provides the supplier's commissioning technicians with the convenience of dining in the staff canteen, and the meal fee is paid by the supplier. In the later stage of equipment installation and commissioning, the supplier will provide on-site equipment management personnel to the buyer. Free training with production operators, including equipment operation, maintenance, etc.

4. The acceptance of the equipment is completed by both the supplier and the purchaser. The purchaser shall provide the acceptance report of the equipment. After the acceptance is passed, the representatives of the supplier and the purchaser shall sign and take effect. The acceptance standard of the equipment shall be in accordance with this design scheme. .

VII. Warranty period and after-sales service:

After the final acceptance of the equipment, the equipment warranty period is one year, excluding wearing parts and consumables.

During the warranty period, the user (ie the buyer) calls and writes due to equipment failure, and the supplier will reply within 4 hours; If you need to send someone to the scene to solve the problem, we will send someone within 48 hours. After the warranty expires, we will continue to provide high-quality service. If the equipment is damaged, we will continue to provide equipment spare parts and equipment at preferential prices Maintenance work.

We promise: No matter what causes the equipment failure, we will first repair the equipment to ensure normal production.

8. Random files:

The random documents include: a certificate of conformity and a manual. The manual provides an overview of the machine, machine installation, operating procedures, Equipment common faults and troubleshooting methods, equipment maintenance, list of main parts, control circuit diagrams and related parameters.

IX. Other conventions:

1. Matters not covered in this design plan shall be resolved through negotiation between the supplier and the buyer.

2. The technical parameters and dimensions provided in this design scheme are for reference only. The data will change during actual production, but the use effect will remain the same.

3. The overall appearance of the machine is beautiful, the installation is standardized, the surface of the machine is painted, and the color of the machine is made according to off-white (factory color), and the buyer can specify the color or provide a color swatch.

4. This design scheme is an annex to the contract and has the same legal effect as the contract.

Purchase Tel: 0769-82261696 13215392671