Products Center

Tel:+86-769-82261696

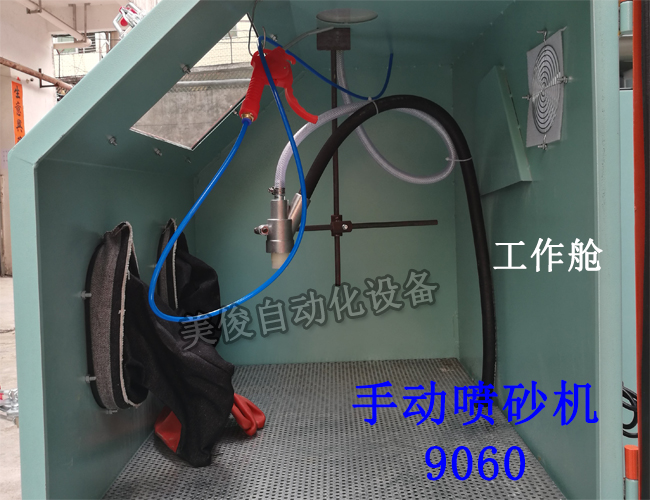

Dongguan Meijun9060Universal manual sandblasting machine, with a wide range of applications: working principle and scope of application: 9060A General pressure dry sandblasting machine, also known as siphon type sandblasting machine, is connected with a gas pipe and a sand pipe at the spray gun. The air pressure is first sprayed through the spray gun body, and a vacuum is instantly formed in the sand pipe. The sand is sucked out and the air pressure at the nozzle is mixed with the sand and sprayed on the surface of the workpiece; it performs extremely small cutting action on the surface of the workpiece, so as to achieve rust removal, oil removal, and scale removal on the surface of metal parts such as molds, castings, stamping parts, etc. , remove burrs, remove residues, etc. and enhance surface adhesion, eliminate internal stress, and prolong service life; engraving, atomization, perforation, anti-skid, etc. on the surface of glass, acrylic, crystal, stone, ceramics, etc. ;Remove fake water marks and burrs of plastic products without hurting the surface of the product, enhance the surface adhesion during fuel injection, and be durable; wood, furniture and other carved patterns to remove wood chips, burrs, etc., the same can also be used. Enhance the adhesion when spraying paint, not easy to fall off. In addition, the surface of all products after sandblasting process has a matte effect and a uniform matte texture. The size of the pinhole on the surface is determined by the type and thickness of the selected sand.

Manual sandblasting machine9060Parameters:

Machine Dimensions: 900X1100X1600 Internal dimensions of working cabin: 900X600X580

Dust Fan: 220V/50HZ/370W Lighting: 220V 13W Energy Saving Lamp

Dust air volume:8.5m3/min Working pressure: 2-7bar(kg/cm2)

Dust removal method: Special bag type dust box for sandblasting, using pneumatic dust removal method, high dust removal efficiency, environmental protection and cleanliness.

User-provided air pump: pressure 2~7BAR ( US">kg/ square meters), flow 0.2-1.0 cubic meters/min

Automatic sandblasting machine, manual sandblasting machine, closed sandblasting machine, dry sandblasting machine, negative pressure sandblasting machine, hardware sandblasting machine, stainless steel sandblasting machine, mold sandblasting machine, decoration sandblasting machine, electronic sandblasting machine, environmental protection sandblasting machine, sandblasting processing equipment,

Use a compressed air hose to connect the air source to the air inlet connector of the sandblaster filter regulator.

Compressed air consumption: (Use gun nozzle aperture 8mm, air nozzle aperture 4mm).

|

compressed air pressure (bar) |

2.8 |

4.2 |

5.6 |

7.0 |

|

compressed air consumption (m3/min) |

0.54 |

0.76 |

0.96 |

1.19 |

Power

Plug the blaster power plug into a 220V\50HZ outlet.

Operating Procedure

Abrasive Loading

Select appropriate abrasives and put them in the storage box according to the processing needs. The amount of abrasives loaded at one time is about 10kg.

Regulation of compressed air pressure

Adjust the filter pressure valve to control the compressed air pressure entering the spray gun according to the work needs, the working pressure can be at 2.8-7bar selection.

Dust cleanup

Clean every 8 hours Dust, the specific operations are: turn off the power switch, step on the dust-removing foot switch at the bottom left 1-2 minutes to shake off the dust by vibrating the dust bag, then open the bottom cover of the dust box, and use a container to hold the dust and dump it out.

How to operate the machine:

Turn on the power switch, the light is on, and the splitter motor starts.

Open the working compartment, place the parts to be processed on the mesh plate, and close the working compartment.

Insert work gloves with both hands, hold the spray gun in one hand, grasp the workpiece with the other, and aim the gun nozzle at the workpiece to be sprayed.

Step on the foot switch lightly, the compressed air is turned on and enters the spray gun, and the abrasive will be injected from the bottom of the tank into the spray gun according to the set spray amount, and sprayed to the surface of the workpiece at high speed under the action of the compressed air superior.

In the process of sandblasting, on the one hand, it is necessary to maintain a proper spray distance and angle between the spray gun and the work space, and on the other hand, the spray gun and the work space should be moved relative to each other, so that the surface of the workpiece is evenly affected by the abrasive. The jet rack is machined until a satisfactory result is obtained.

After machining, the foot must be removed from the foot switch, and the work bay door can be opened and the part removed after the gun stops spraying abrasive.

If you need to continue machining parts, do not turn off the power in the middle.

If you stop working after work, you should turn off the power.