The working principle, characteristics, structure and precautions of the spray tower

The acid mist exhaust gas is introduced into the purification tower through the air duct, and after passing through the packing layer, the exhaust gas and the sodium hydroxide absorption liquid undergo a gas-liquid two-phase full contact absorption and neutralization reaction. The fan exhausts into the atmosphere. The absorption liquid is pressurized by the water pump at the bottom of the tower and sprayed down at the top of the tower, and finally refluxed to the bottom of the tower for recycling. The purified acid mist exhaust gas meets the emission requirements of local emission standards and is lower than the national emission standards.

Features of spray tower

1. High dust removal and desulfurization efficiency, when using alkaline washing water, the desulfurization efficiency can reach 85%;

2. The equipment occupies less area and is easy to install;

3. Low water and power consumption indicators;

4. Corrosion resistance, no wear, long service life;

5. The equipment operates reliably, and the maintenance is simple and convenient.

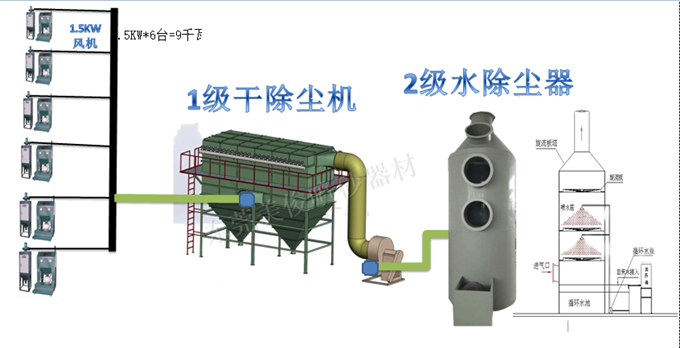

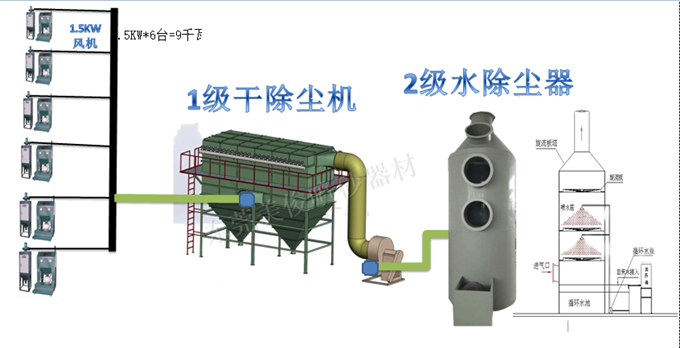

Spray tower structure

The packing layer in the spray tower is used as a mass transfer device for the contact components between the gas and liquid phases. A packing support plate is installed at the bottom of the packed tower, and the packing is placed on the support plate in a random manner. A packing pressure plate is installed above the packing to prevent it from being blown by the updraft. The spray liquid of the spray tower is sprayed onto the packing from the top of the tower through the liquid distributor, and flows down along the surface of the packing. The gas is fed from the bottom of the tower, and after being distributed by the gas distribution device, it continuously passes through the gap of the packing layer in countercurrent to the liquid. On the surface of the packing, the gas-liquid two phases are in close contact for mass transfer. When the liquid flows down the packing layer, the phenomenon of wall flow sometimes occurs. The wall flow effect causes uneven distribution of the gas-liquid two phases in the packing layer, thereby reducing the mass transfer efficiency. Therefore, the packing layer in the spray tower is divided into two sections, and a redistribution device is set in the middle, and after redistribution, it is sprayed onto the lower layer of packing.

Precautions for the use of spray towers

1. Adjustment of circulating water volume: It is determined by the water supply pump of the spray tower. When running one boiler, one can be opened. When two or three are running at the same time in winter, all two pumps are turned on, and the flow rate of the mud pump is It should be adjusted according to the flow of the circulating pump to make it equal.

2. Dosing amount in the dosing tank in the spray tower: When running one boiler, add 2 bags of alkali and 5 bags of slaked lime. If two or three units are running in winter, the dosage can be increased according to the corresponding multiples.

3. The sedimentation tank of the spray tower should be cleaned frequently, once a week in summer and once every three days in winter.

4. When the sewage is discharged from the grey water separator, it is discharged once per shift, and the sewage valve should be opened separately until the clean water is discharged.

5. The above rotating parts should be checked and oiled frequently, and faults should be eliminated in time to ensure the desulfurization effect of the spray tower.

6. Pay attention to safety when adding medicines up and down the stairs, and have independent security and mutual security awareness.

7. After the work is completed, it is necessary to clean up the hygiene in time, so that people can leave the site clean.

The principle of the tower is water spray, which is basically used in chemical, pharmaceutical, electroplating, metallurgy, machinery and other places

Company address : No. 33, Xinxing Road, Xinlian Community, Humen Town, Dongguan City

Company Tel: 0769-82261696 Mobile: 13215392671 (WeChat )

Company website: http://www.dgmagin.com