Products Center

Tel:+86-769-82261696

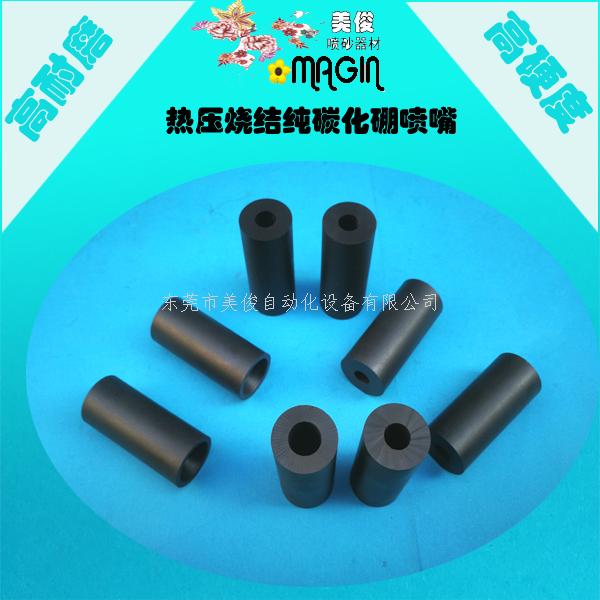

Boron carbide nozzle, boron carbide nozzle, boron carbide sandblasting nozzle, boron carbide sandblasting gun, boron carbide gun head manufacturer

Hot-pressed sintered pure boron carbide nozzle with good quality, high hardness, strong wear resistance, 15 years Brand management, factory-produced direct supply for wholesale, more favorable price, quality guaranteed.

Dongguan Humen Meijun Sandblasting Equipmentboron carbide nozzleFeatures:

Compared with other companies' products, we guarantee:

1) High temperature sintered boron carbide products, high hardness, high toughness, high wear resistance, long life;

2) The appearance is neat and clean .

3) Outer circle and inner hole with high roundness;

4) It is guaranteed to be sintered with pure boron carbide micropowder, and it is pure boron carbide without any other materials.

Hot-pressing high-temperature furnace sintered boron carbide nozzle performance characteristics Has the same performance as boron carbide:

The cross section is a spiral radial pattern. The basic shape of the nozzle is a cylinder and a cone. It is difficult to make special shapes and steps.

1) Very hard and wear-resistant

2) No reaction with acid and alkali

3) High, low temperature, high pressure resistance

4) Density≥2.5g, cm3;

5) Microhardness≥3500kgf/mm2;

6) Bending strength≥400Mpa;

7) The melting point is 2450℃.

Because of the above characteristics of wear resistance and high hardness of boron carbide nozzles, boron carbide sandblasting nozzles require wear resistance. of industries already

Gradually replace known cemented carbide tungsten steel and sandblasting nozzles made of silicon carbide, silicon nitride, alumina, zirconia and other materials.

Estimated nozzle life: 800 hours (reference)

The aging time is more than 5-10 times that of the tungsten steel nozzle!

|

Nozzle material |

Reference service life under different blasting media |

||

|

glass beads/hour |

Quartz sand/hour |

Brown corundum/hour |

|

|

Alumina Ceramic Nozzle |

20-40 |

10-30 |

1-4 |

|

Carbide tungsten steel nozzle |

500-800 |

300-400 |

20-40 |

|

High temperature sintered boron carbide nozzle |

600-1000 |

400-600 |

50-100 |

Regular stock specification:

Outer Diameter 20MM Series: Inner DiameterΦ(1.05-12)*Outer Diameter 20MM*Length 35/45/50/60 /80/82MM

Outer Diameter 15MM Series: Inner DiameterΦ(1.05-10)*Outer Diameter 15/16MM*Length 35/40/55MM ;

Outer Diameter 28MM Series: Inner Diameter Φ10/12/14mm*Outer Diameter 28MM*Length 75/80M

Carbonization Boron nozzle, sandblasting nozzle, boron carbide sandblasting gun, boron carbide nozzle

Unconventional special models:According to Customers provide drawings and dimensions for processing and production, welcome to customize drawings.

Features:

Boron carbide is one of the hard man-made materials, with light weight, semiconductor properties, neutron absorption, high grinding efficiency, and strong acid\alkali No response, etc.

Mohs hardness is 9,36, microhardness is 5400-6300 kg per square meter, density is 2.52 kg per square meter, melting point is 2450 Celsius,

Boron carbide nozzle, sandblasting nozzle, boron carbide nozzle, spray gun nozzle

Boron carbide is hexagonal dark black. Due to the above characteristics and properties, boron carbide is widely used in machinery, metallurgy, chemical industry, aerospace

and other fields,

Abrasives can be made to process gemstones, ceramics, bearings, used as refractory materials in various fields of metallurgy,

Dongguan Humen Meijun Sandblasting Equipment" Magin "brand Using high-purity hard materials, using high-fine, high-purity, and ultra-fine boron carbide powder as

The raw material is produced by hot pressing and high temperature sintering technology. The product fully considers the needs of many manufacturers for high nozzle life, and is continuously improved. After many large-scale glass

Glass deep processing, electronic manufacturing, hardware die-casting and other enterprise applications have truly achieved a balance of cost performance and are well received by manufacturers. The products have been stably supplied to Hong Kong and Taiwan

Customers are sandblasting machinery manufacturers, shipyards, ship maintenance, marine engineering equipment factories, hardware processing factories, glass deep processing, solar energy industry,

Photovoltaic industry, wind power generation industry, automobile industry, IT manufacturing, petroleum industry, mold and flower factory, die casting factory, wheel hub factory, chip factory, HardwareFactory, spraying factory, oxidation factory, electroplating factory and other enterprises with large demand for sandblasting machine accessories