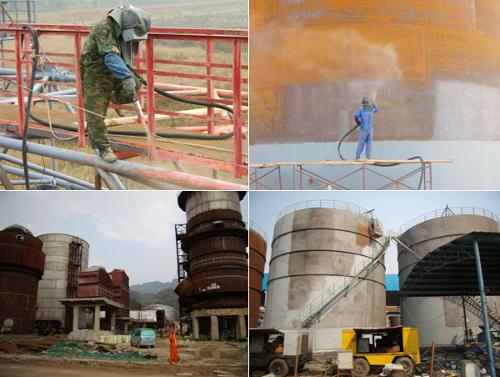

Pressure Mobile Sandblasting Machine | Rust Removal Sandblasting Machine | Steel Structure Sandblasting Machine

600 sand cylinder diameter

Pressure-holding pneumatic control type:

Features: The sandblasting machine operates automatically for each operation, and it is operated by one person, which is simple and convenient.

Pressure mobile sandblasting machine is a thermal spraying pre-treatment machine, powered by compressed air, sprays clean and dry abrasives to the surface of the workpiece to be sprayed at high speed to achieve surface cleaning,

It can also be used to remove paint, remove rust from welds, prepare frosted glass and other workpieces, and the effect is very significant. The cleaning level reaches SA2.5-3.0, and its roughness reaches

process requirements. The product has the characteristics of wide application, compact structure, simple maintenance and convenient use. It is a necessary machine for thermal spraying (welding) various anti-corrosion layers.

The pneumatic remote control system of the pressure-maintaining pressure mobile sandblasting machine consists of an air shut-off valve, a control air pipe, a manual control switch and an air-controlled sand control valve assembly.

Depress the handle when working, control the air flow through an air pipe (the A port on the cut-off valve is flushed out) to the manual switch, and then discharge to the cut-off valve through another air pipe Air intake (B port), so that

The main pipeline intake valve in the stop valve is opened to open the air source channel into the sand tank and the main gas pipe on the cylinder side. At the same time, the air source outside the B port is exhausted from the three-way through the stop valve Mouth (c mouth)

Flush out to the sand control valve, the sand control valve is opened, the pressure in the sand tank rises at this time, and the sand-gas mixture is pressed out from the bottom of the cylinder through the open hole of the sand valve rubber core to the sand production Tee, sandblasting operation begins.

The feature of this model is that every time the switch, air shut-off valve (intake valve), and air-controlled sand control valve must be activated, the gas in the sandblasting cylinder will increase and discharge, and every time one time switch

There is a certain time, because the operator can put down the nozzle after all the gas in the sandblasting cylinder is exhausted.

, beam return, sand control valve

Open. Therefore, every time the switch is turned on, there will be a certain amount of storage in the sand tube, and there will be an instantaneous pulse when the gun is fired.

The system is not suitable for sandblasting operations with a length of more than 20m, because the pneumatic remote control response has a lag time.

Shorten the reaction time. If you must use pneumatic control to switch to a 45-degree manual butterfly-shaped sand control valve, you have to endure a delay of 3-5 seconds, or use our new air cut-off valve.

Stop valve (new design, with the addition of D port for the instant exhaust port of the control pipeline), which can be exhausted instantly, reduce the delay, and can produce a control response in 1 second.

一、System parameters of this model:

1. Main technical parameters and structure of the equipment

1) Main technical parameters

|

Cylinder Diameter:600mm

Sandblasting efficiency: 15-35 square meters/H

|

|

Cylinder heightSpend:1300mm Sandblasting grade:SA2.5-3.0

|

|

Capacity Product: 0.3 cubic Air consumption: ≥3 cubic/min

|

|

Use air pressure: 0.6-0.7Mpa

|

|

Features: Pneumatic control, low failure rate, less wearing parts, less investment, high efficiency, wheel structure, fixed-point and mobile sandblasting, easy to move.

|