Products Center

Tel:+86-769-82261696

Dongguan Meijun Sandblasting Equipment, specializing in the production and sales of high wear-resistant boron carbide nozzles for more than ten years, is one of the earliest companies engaged in the production and sales of sandblasting machine accessories. The source manufacturer of sand machine and sandblasting machine accessories and consumables.

After more than ten years of development, it has developed into a comprehensive sandblasting industry manufacturer integrating the production and sales of professional sandblasting machines, shot blasting machines, sandblasting wear-resistant materials and related sandblasting machine accessories.

Steel structure processing sand blasting machine rust removal sand blasting machine steel plate sand blasting oil tank sand blasting machine stone carving sand blasting machine glass fiber reinforced plastic sand blasting machine, surface passivation sand blasting machine, paint removal sand blasting machine, welding scar removal sand blasting machine, Stainless steel cleaning sandblasting machine

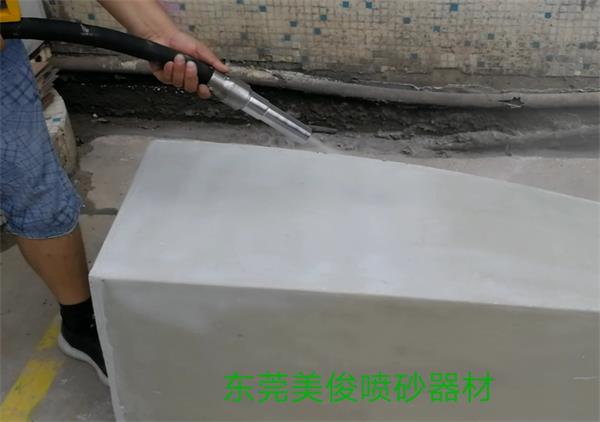

The pressure-type open-type mobile sandblasting machine series products are widely used in derusting and demoulding, wax removal and surface passivation treatment of glass fiber reinforced plastic products, gypsum products, resin products, decorative products, stone, jade and other products. It is also used for glass, marble, etc. High-efficiency processing machine for sandblasting and three-dimensional engraving of stone, sandblasting of shipbuilding, surface treatment, rust removal, anticorrosion treatment and fancy sandblasting of denim clothing before painting of bridges, railways, containers, petrochemical facilities and other steel structures.

The automatic pressure relief and pressure type open mobile sandblasting machine produced by Dongguan Meijun Sandblasting Equipment (steel structure rust removal and anticorrosion sandblasting machine) is an automatic sandblasting machine with automatic safety guarantee performance operated by one person. It is easy to use and easy to use. The damaged parts are separated from the cylinder parts, reducing the cost of replacing consumables. At the same time, our tanks are welded by large-scale machines to ensure product quality.

Features that are different from other manufacturers of open sandblasting machines:

The pressure-relieving automatic exhaust pressure-type open mobile sandblasting machine produced by Dongguan Humen Meijun Sandblasting Equipment has the advantages of safe use and the safety guarantee of the air pressure throughout the operation is less than 8KG.

The air pressure is generated when the machine is turned on, and the air pressure is removed when the machine is turned off. All operations are controlled by only one person through the control switch on the hand, which is simple and applicable. Welcome to understand!

Pressure type open sand blasting machine, steel structure sand blasting machine, rust removing sand blasting machine, oil tank sand blasting machine, pipeline sand blasting machine

Machine parameters:

Sand tank diameter: 600MM Sand tank height: 1300MM

Sand tank volume: 0.3 cubic meters

Derusting efficiency: 15-30 square meters / hour

Air consumption: 3 cubic meters per minute (single gun)

Air source pressure: 0.6-0.7MPA

By configuration:

1)Basic type: pure manual type, basically pressure-retaining assembly.

2)Pressure maintaining type: electric control type or pneumatic control type

3)Pressure relief type: electric control type or pneumatic control type

Advantages of using pressure type open sandblasting machine:

It can replace the pickling and phosphating process, and does not involve the problem of sewage. Rapid sand blasting and rust removal can also remove welding slag, burrs and burrs while changing the surface roughness. High efficiency, low cost and good quality are unmatched by traditional chemical and manual rust removal. After sandblasting, the paint quality is good and the coating life is long. It is a general process method currently used internationally.

Applicable scope of pressure type open mobile sandblasting machine:

Mainly used for: surface cleaning, rust removal, paint removal, oxide layer, engraving, spray processing, descaling, burr, welding scar, glass shot, strengthening the surface of decorative parts. It is a necessary process for the pretreatment of spraying and electroplating (all surface treatments to improve the adhesion of the coating surface)

Derusting sandblasting machine belongs to one of the series of pressure mobile sandblasting machines, which are mainly named for the purpose of sandblasting operation.。

Other names:

Steel plate sandblasting machine Oil tank sandblasting machine Stone carving sandblasting machine FRP sandblasting machine, surface passivation sandblasting machine, paint removal sandblasting machine, welding scar removal sandblasting machine, stainless steel cleaning sandblasting machine

Dongguan Meijun sandblasting equipment rust blasting machine features:

1,Compact structure, superior performance, simple and convenient operation.

2,The design and production of the cylinder body conform to the pressure vessel standard, which is safe and reliable.

3, using standard common parts, easy to replace, lower cost.

4,The instant control function is installed, and electric control or pneumatic control is adopted to meet the different needs of customers, and it can be operated by one person alone.

5, The shell is sandblasted and uses advanced anti-rust paint to prevent rust.

6, add wheels, easy to move.

◆Advantages of using pressure sandblasting machine to remove rust:

In view of the current high requirements for environmental protection and the high cost of purchasing environmental protection equipment or building environmentally friendly sewage treatment tanks, many companies are feeling headaches. It can replace the pickling and phosphating process, and will not involve the problem of sewage. Forget a big, insurmountable problem.

Steel structure derusting sandblasting machine can quickly blast and derust, while changing the surface roughness, it can also remove welding slag, burr, and flash. High efficiency, low cost and good quality are unmatched by traditional chemical and manual rust removal.

The paint spraying after sandblasting has good quality and long coating life, which is 3-4 times longer than that before sandblasting. It is a general process method adopted internationally.

Pressure mobile sandblasting machine series products are widely used in steel structure rust removal and glass fiber reinforced plastic products, gypsum products, resin products, decorative products, stone, jade and other products demoulding wax removal and surface passivation treatment.

Pressure mobile sandblasting machine is the simplest, low-cost and mature technology for sandblasting and three-dimensional engraving of glass, marble and other stone materials,

Pressure mobile sandblasting machine is also a professional and high-efficiency treatment for surface treatment, rust removal, anti-corrosion treatment and fancy sandblasting of denim clothing before painting of shipbuilding, bridges, railways, containers, petrochemical facilities and other steel structures Machine.

Characteristics that distinguish it from other manufacturers of open sandblasting machines:

The pressure relief type automatic exhaust pressure type open mobile sandblasting machine produced by Dongguan Humen Meijun Sandblasting Equipment has the advantages of safe use and the safety guarantee of the air pressure throughout the operation is less than 8KG.

The air pressure is generated when the machine is turned on, and the air pressure is removed when the machine is turned off. All operations are controlled by only one person through the control switch on the hand, which is simple and applicable. Welcome to understand!

Using rust-removing sandblasting machine to blast glass fiber reinforced plastic products and resin products can quickly clean the wax attached to the surface after demoulding, passivate the surface of the product, increase the roughness, and make the subsequent painting, batch powder The adhesion is increased and the service life is increased by 3-5 times.

After experiments, it can save labor by 20 times and increase efficiency by 40 times.

Application cases of pressure mobile sandblasting machine in glass fiber reinforced plastic, resin products and handicraft industry:

A FRP mask model the size of a human face, it takes 5-8 minutes to grind with a manual hand grinder, and it takes about 10 seconds if you use a rust-removing sandblasting machine. If the sandblasting machine is moved, the efficiency will be higher, which can save a lot of labor and increase the efficiency of product forming..

◆Machine parameters:

Sand cylinder diameter: 600MM Sand cylinder height: 1300MM

Sand tank volume: 0.3 cubic meters

Derusting efficiency: 15-30 square meters/hour

Air consumption: more than 3 cubic meters per minute (single gun) Use a small sandblasting pipe with an inner diameter of 13MM, the flow rate can be reduced

Air pressure:0.6-0.7MPA

The control method of Dongguan Meijun rust blasting machine:

By configuration:

1) Basic steel structure descaling sandblasting machine: pure manual type, basically a pressure-maintaining assembly.

Inlet valve (ball valve control switch) + sand adjusting valve (ball valve control switch). Without electric control and pneumatic control system, 2 people are required to operate at the same time, one person takes a gun to blast the workpiece, and the other person controls the machine switch.

2) Derusting sandblasting machine for pressure-maintaining steel structure: electric control type or pneumatic control type

Intake valve (aluminum alloy globe valve) + sand control valve (EMPAIR air-controlled sand valve or manual sand valve).

The sand tank is always under pressure and needs to be relieved manually.

The characteristic is: no matter any switch on the spray gun, as long as the exhaust ball valve on the top side of the sand tank is not opened, the pressure in the cylinder will not be released (except for the self-discharge of the manual sand valve: it will cause serious sand accumulation in the sand pipe). ), suitable for short-term point blasting.

3) Derusting sand blasting machine for pressure relief steel structure: electric control type or pneumatic control type

Inlet valve (aluminum alloy globe valve) + sand control valve (EMPAIR air control sand valve or manual sand valve) + automatic air control exhaust valve.

When the sand tank is blasting, the pressure in the tank is the working pressure, and the pressure in the tank is 0 when it stops. It is suitable for long-term large-area blasting.

The pressure in the tank will never exceed the limit pressure, which plays the role of safety guarantee and is also a necessary assembly method for automatic sand return.

◆Working principle of pressure sandblasting machine:

The pressure-type open-type mobile sandblasting machine of Dongguan Humen Meijun Sandblasting Equipment adopts a pressure-feeding sandblasting (shot peening) mechanism, that is, the compressed air flows at a high speed in the high-pressure tank to form a high-pressure effect, and the sand in the high-pressure tank is discharged. It is sprayed through the sand conveying pipe, and then sprayed onto the surface of the workpiece at a high speed from the spray gun nozzle with the compressed air flow, so as to achieve the purpose of sand blasting cleaning.。

◆Scope of application of pressure type open mobile sandblasting machine:

Mainly used for: surface cleaning, rust removal, paint removal, oxide layer, engraving, spray processing, descaling, burr, welding scar, glass shot, strengthening the surface of decorative parts. It is a necessary process for the pretreatment of spraying and electroplating (all surface treatments to improve the adhesion of the coating surface)

The series of pressure mobile sandblasting machines are widely used in

1) Glass, marble, ceramic tile, mold, fitness and amusement equipment and other surface sandblasting cleaning and three-dimensional carving and carving operations;

2)Sandblasting for shipbuilding, surface treatment, rust removal and anti-corrosion treatment for steel structures such as bridges, railways, containers, oil pipelines, chemicals, mining facilities, water conservancy projects, port construction, etc. before painting;

3)Fancy sandblasting for denim clothing;

◆Abrasive Control:

Sand for sand blasting and rust removal requires hard particles, angular, dry and free of soil and other impurities;

Quartz sand is better, but coarse river sand is also acceptable; at the same time, sand transportation conditions, unit price, and recycling capacity should be considered

Factors such as force; the particle size of sand should be 0.5-1.5mm, and it must be dried and stored before screening

In the shed and indoors, the size of the sieve holes is: coarse sieve 40-48 holes (particle size 1.2mm), fine sieve 372-476 holes

(Particle size 0.3mm)

◆Air source requirements:

Compressed air must be treated by cooling device and oil-water separator to ensure dry and oil-free;

The oil-water separator must be cleaned regularly;

The air pressure of the air compressor is6.0×105~6.5×105Pa,The pressure change is

0.5×105~1.0×105Pa。Generally, the air pressure of the sand bucket is 4.5×105~5.5×105Pa, not less than

4.0×105Pa。

◆Operation protection requirements of rust blasting machine:

The non-sandblasted parts should be shielded and protected before sandblasting。

Before sandblasting, check whether the various pipes and control valves of the sandblasting machine are well connected, and whether they are in the appropriate switch positions.

Whether the protective tools, safety belts (ropes) and oxygen supply devices worn by sandblasters are safe and reliable, as well as the wear of the nozzles, when the orifice is worn

The nozzle should be replaced when the diameter increases by 25%.

Operation control of rust blasting machine for steel structure:

When sandblasting, the distance between the spray gun and the surface of the base steel should be 100-300mm.,

The angle between the spraying direction and the normal to the surface of the base steel is preferably 15° to 45°.

After sandblasting and rust removal, before proceeding to the next process, in case of rain or other conditions that cause the surface of the base steel to be wet, after the environment reaches the construction conditions, dry the surface moisture with dry compressed air before proceeding Sandblasting construction. If it is necessary to re-blast, the abrasive requirements cannot be reduced, so as not to reduce the roughness and cause low adhesion of subsequent spraying.

Company Name: Magin Dongguan Humen Meijun Sandblasting Equipment Store

Address: 1-1, Building A, Qihe Industrial Park, No. 33 Xinxing Road, Xinlian Community, Humen, Dongguan City

Telephone:0769-82261696 contact phone:13215392671 13238321213

http://www.dgmagin.com elsonzhong@163.com QQ:491440166