Products Center

Tel:+86-769-82261696

The sandblasting machine produced by Dongguan Humen Meijun Sandblasting Equipment has a wide range of applications: suitable for sandblasting and rust removal, sandblasting surface cleaning, increasing surface roughness, acrylic surface, matte surface, polishing, refurbishment and deburring, sandblasting engraving, engraving and other uses.

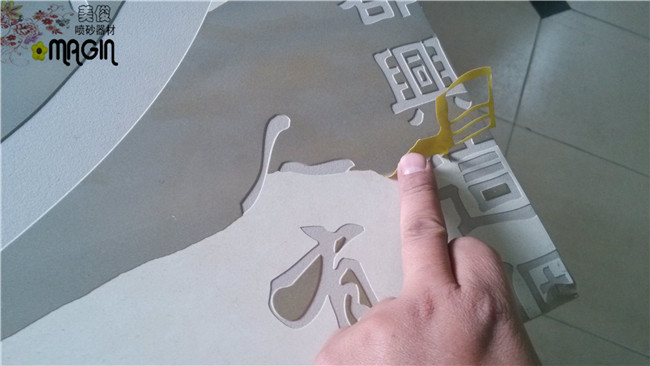

Its working method is to use computer typesetting to engrave the content to be engraved on the self-adhesive paper through a computer engraving and cutting machine, which is called sandblasting protective film, and stick the engraved protective film on the object to be engraved. When the high-pressure air drives the emery to hit this part, the effect is like hitting this part with tens of thousands of chisels with large sand grains at the same time by hand. The parts that need to be engraved will be removed. On the contrary, if the film is protected by the film, because the film is soft, the hard part will bounce off when it touches the soft part.

The depth of engraving depends on your processing requirements, and the length of time the spray gun stays in determines the depth of engraving. If you want to carve deeply, just spray more on the place where you need to carve deeply. There is no difficulty in this technique. Generally, a normal person can do it in a few minutes without any foundation. The engraved content is the same as the one that comes out of the computer. It is neat and beautiful, and it is not deformed or out of shape. The cost of engraving is low and the speed is fast. Generally, the cost of engraving materials for one square meter is about 12-20 yuan, including protective film, electricity, emery, and the engraving speed is fast. Just a few seconds. This is incomparable to traditional manual and other CNC tool engraving.

Sandblasting engraving is an engraving method that uses high-pressure air to drive abrasives such as emery to hit the surface of the stone at high speed, so as to achieve the engraving effect. It uses a cutting plotter to engrave the content to be engraved on the self-adhesive paper, uses the self-adhesive paper as a sandblasting protective film, sticks the protective film with the engraved content on the surface of the object to be engraved, and removes the part of the content to be engraved. Parts, control the sandblasting gun for sandblasting engraving.