Products Center

Tel:+86-769-82261696

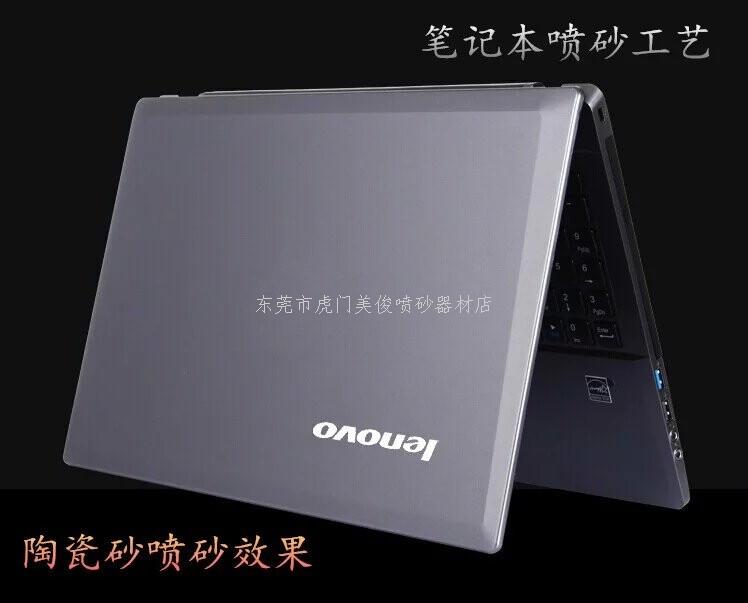

How is the matte matte surface of the digital product frame and shell formed? What are the advantages?

We often see frosted and matte products in our lives. Common frosted products in our lives include: decorations, mobile phone shells, computer shells, cups, TV shells, rice cookers, furniture, refrigerators, lampshades , glass doors and windows, tiles and other common or uncommon products in life or industry

What are the product features of the frosted surface: effective scratch resistance, matting, no fingerprint residue, and layered to the touch

What are the effects of sandblasting on the surface of Dongguan Humen Meijun sandblasting equipment:

1. Surface cleaning and beautification processing

Metal oxide skin, carbide black skin, metal or non-metal surface rust removal, ceramic surface black spot and color removal or color painting regeneration. Gravity die-casting molds, removal of oxides, residues or release agents from rubber molds, decorative processing of various metal products, and matting or matte treatment of various gold, K gold ornaments, and precious metal products. Crystal, glass, poly, acrylic and other non-metallic matte processing and can make the surface of processed objects into metallic luster.

Matte surface and etching of silicon wafers, removal of backside of wafers, spraying of overflowing glue burrs in electronic parts packaging, removal of printing on the surface of finished products, cleaning of ceramic electric heating

Derusting, paint removal and maintenance of large workpieces such as oil tanks, chemical tanks, copper hull structures, iron houses, containers, and automobile industries. Automatic matte treatment of large flat glass and processing of five-foot to nine-foot wide glass at one time, sandblasting of large aluminum plates, saving time and effort。