As a mechanic, you must be familiar with burrs. In the machining process, it is ubiquitous, no matter how advanced and sophisticated equipment you use, it will be born with the product. Some burrs on mechanical parts are caused by plastic deformation during the cutting process; some are burrs from casting, die forging, etc., and some are residual materials from welding and extrusion. The existence of burrs will have adverse effects on the machining accuracy, assembly accuracy, reprocessing positioning and appearance quality of the parts, etc.

Deburring refers to the removal of extremely fine surface Microscopic metal particles, these particles are called burrs. They are formed during cutting, grinding, milling and other similar chip machining processes. For travel quality and service life, it is necessary to remove burrs on all metal fine parts. Workpiece surfaces, sharp corners and edges must achieve extremely high metal cleanliness and, if necessary, should be suitable for non-plated and plated metals. Traditional mechanical processes for deburring, such as grinding, polishing and other processes with varying degrees of automation. The quality of the workpieces being processed is often not guaranteed; production costs and personnel costs are very high. Using the deburring process of the burr machine, put the workpiece into a barrel with abrasive materials and grind it for 3-15 minutes. It can remove all the fine burrs of fine parts, make the surface of the workpiece smooth and flat, and the edges and corners are smooth, bringing users unprecedented high quality. And it will not affect the fineness of the product. Deburring with a burr machine is not only environmentally friendly but also saves a lot of production and personnel costs.

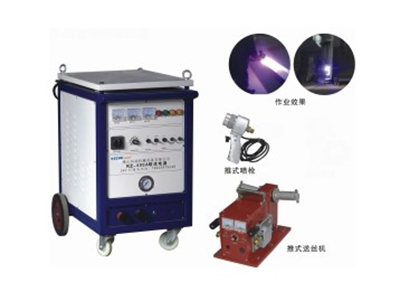

burr processing machine The burr process is a method of mechanical processing, using a product called "deburring machine". Breaking the traditional vibration polishing concept, the projecting material is projected on the product by the high-speed rotating impeller, bumping the fragile burr parts, and the flaky burrs and the burrs in the recesses or holes can be removed in a short time. The size of the projection force can be adjusted to the appropriate number of revolutions on the inverter keyboard on the control panel to achieve high-efficiency removal of burrs, burrs, burrs, and peak edges. After the product is new, let people shine. Product quality is a straight line trek. The surface and inner holes of fine parts (including CNC, machining centers, CNC lathes, lathe parts, turning parts, screws, die-casting parts, stamping parts, automatic lathes and other processed products) are deburred and brightened at one time.

Features of the burr processing machine of Meijun sandblasting equipment:

[Crawler sandblasting machine]Features:

1. The upper cyclone is separated, the dust removal split mechanism has high working efficiency, and the bag dust removal effect is good

2. Low working noise and no dust spillage;

3. Automatic recovery of abrasives, good sorting effect and low operating cost;

4. The effect of spraying on special-shaped parts is uniform;

5. No other installation required, easy to operate.

Scope of application:

1. Various small and medium-sized workpieces, continuous production in large quantities;

2. It is suitable for all kinds of die-casting, small hardware products or non-metallic products to deburr, residue, oil stains into matt effect or glossy effect.

【Thermosetting plastic burr processing sandblasting machine】

The best automatic machine specially designed for burr cleaning of thermosetting plastics, bakelite and resin products such as compression and injection molding.

1. The dust collector is hidden in the body.

The input port and the operation panel are well arranged, which is easy to operate and maintain.

2. The projection material is shot by the high-speed rotating impeller, the radiation area is large, the projectiles are dense, the surface of the product, the inner hole, the concave part, the burr of the difficult part can be cleaned in a short time, and its high efficiency cleaning ability.

3. After the products are processed by this machine, they are all beautiful and shiny. (Because this machine is equipped with automatic humidification and automatic blowing device to remove dust)

4. This machine can be used continuously for a long time without replacing parts, so the maintenance cost is low, and it can be processed in large quantities. Each machine can be used for 10~15 people. It is a good helper to reduce costs and reduce labor. .

This machine is used to process the surface burrs of compression or injection molding thermosetting plastic products.

Abrasive ejection is a self-contained projection device, which integrates a chassis, a belt conveyor, a dust collector, etc.

The burr machine is suitable for non-magnetic products such as stainless steel, copper, aluminum alloy, zinc alloy, titanium alloy, hard plastic, light iron and other metals. Work habit planning is extensive. Such as jewelry handicraft work, electronics, communications, machinery, medical, aerospace and so on. This method is simple and requires no professional operation. It is possible to deburr workpieces with very complex structures (for example: inner corner holes) or simple damaged parts or easily bendable parts without damaging the workpiece, so as to obtain finer workpieces. Compared with the traditional deburring method, it is simpler, more cost-effective, and more labor-saving, and the quality of the workpiece is greatly improved.