Recycle method:

1、belt conveyor + bucket elevator + separator 2、scraper + belt + bucket elevator + separator 3, screw conveyor + bucket elevator + separator

System Features:

1. This system uses mechanical power to recycle abrasives, sandblasting abrasives It can be selected arbitrarily, the abrasive is recycled, and the processing efficiency is high;

2.The machine adopts two-stage dust removal, and its total dust removal efficiency can reach more than 99.99%;

3.The machine is equipped with a system air volume adjustable device to balance The recovered sand will not enter the filter element dust collector, reducing the loss of sand and achieving the best dust removal effect;

4.The main electrical components are imported products, which have stable performance, safety and reliability, long-term use and simple maintenance;

5.On the upper part of the front roof of the sandblasting room, there is a "sound and light alarm system". In the sandblasting room, there is an emergency stop call button;

6. The electronic control of each system adopts interlocking control. When the system fails, the related systems stop working, and the spray gun stops spraying.

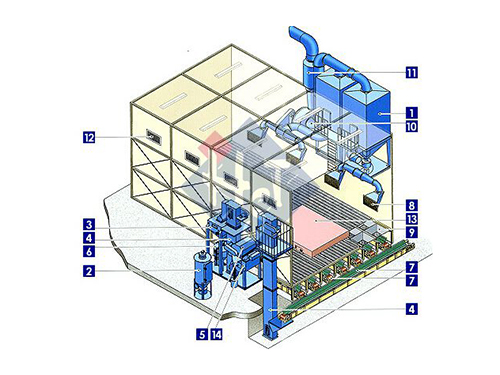

Automatic mechanical conveying recovery type sand blasting room/shot blasting room system

Source system, sand blasting/pellet system, abrasive recovery and separation system, ventilation and dust removal system, workpiece conveying system, labor protection system, lighting system and electrical automation control system; sand blasting room/shot blasting room is mainly used for construction machinery, bridges Surface sand blasting and shot blasting for steel structures, heavy machinery, containers, rolling stock, aerospace, petroleum and petrochemical, electric power, weapons and other industries. The company adopts advanced modular design, factory prefabrication, and on-site assembly; the structure is reasonable and beautiful, and the design and manufacturing cycle can be controlled within 1 to 3 months.

The fully automatic mechanical conveying and recycling sand blasting room/shot blasting room adopts the method of mechanical conveying and recycling of abrasives, which has changed the method of pneumatic conveying and recycling that has been used in the 1980s and 1990s. The method of mechanical conveying and recycling is more efficient, more environmentally friendly, and has a lower cost of use. It is 20 times more efficient than the same type of pneumatic conveying recovery method and saves 80% of energy.

Sand blasting room/shot blasting room process: workpiece feeding → sand blasting/pellet → recycling → screening → dust removal → workpiece output, the process can be automatically controlled.

| Sandblasting/Pill room result diagram: 1. Chamber dust collector 2. Sorting and dust removal Device 3, Sand (Pill) Hopper 4, Bucket Elevator 5, Primary Separator 6, ACM Sandblasting Machine 7, Belt Conveying Mechanism 8. Dust suction port 9, honeycomb floor hopper 10, large fan 11, muffler 12, air inlet 13, ground rail trolley 14, secondary Detach |