Products Center

Tel:+86-769-82261696

Applicable scope of van type water sandblasting machine: Hand accessories industry, stainless steel Product industry, old parts renovation, mold cleaning, electronic hardware plastic Acrylic resin and other workpieces or handicraft sandblasting.

1) Main unit dimensions: 900*900*1550mm

2) Working cabin size: 680*680*600

3) Separator motor: 220V/50HZ/1500W

4) Cabin material: FRP

Note:

1. The body is made of glass fiber, which is durable and will not corrode.

2. The operation of the airbag foot switch control equipment is safe and reliable.

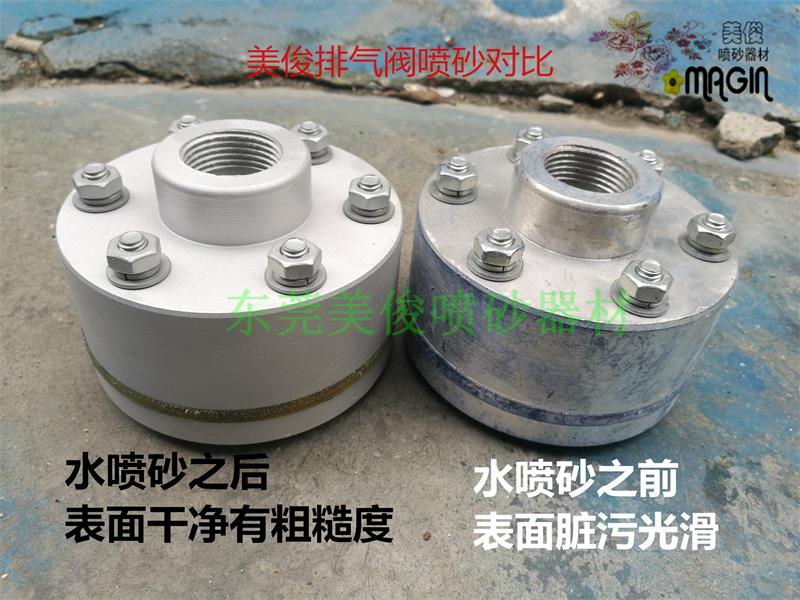

3. The sandblasting effect is obviously different from dry sandblasting, which is suitable for finishing.

Application of liquid spray noise

(1) Clean the rough surface of precision castings

The use of liquid spray to clean the dense casting can not only remove the oxide scale and residues on the surface of the casting, but also play a role in polishing. Improve the surface finish of castings. Especially for precision castings with complex shapes and no sheer weight, it is a cost-effective process to use liquid jet cleaning and polishing, such as aero-engine turbine blades.

The use of liquid spray to clean the die-casting parts can make the parts reveal the metal color of the same color and make the appearance of the parts more beautiful. If liquid shot peening is used, the effect is better, and at the same time, the surface hardness and corrosion resistance of the parts can be improved. Liquid shot peening can also achieve the role of decoration, such as various instrument shells, frames, etc.

The high surface quality can also be obtained by liquid spraying for sand casting aluminum alloy and copper alloy. The liquid spraying process is generally not recommended for rough cast steel and cast iron parts.

(2) Remove oxide skin

The oxide skin and residual salt after heat treatment can be cleaned by liquid spray to remove the oxide skin and improve the finish of the parts. Especially for moulds with complex shapes and precision parts, the liquid spraying effect is more prominent. For example, the use of liquid spray after heat treatment not only damages the cutting edge of the file, but also improves the service life of the file.

All kinds of metal sheets after hot rolling can also be used to remove oxide scale and stains by liquid spraying to prepare for cold rolling and improve the surface quality of the sheet.

(3) Remove microburrs from machined parts

The burr is small and very harmful. With the advancement of science and technology, the shape of mechanical parts is becoming more and more complex, and the precision requirements are getting higher and higher. The application conditions are very strict, and a little burr is not allowed, such as textiles. Mechanical parts, hydraulic components, sophisticated and complex parts of the aerospace industry, equipment, etc., use liquid spray to remove burrs with high efficiency and high quality, so that a small round angle appears at the junction of the two surfaces, (this is the requirement of many mechanical parts. ) If the process parameters can be reasonably selected, the original surface luminosity can be improved.

(4) Clean up dirt and rust

Various molds, such as forging dies, stamping dies, tire molds, plastic compression dies, glass molds, etc., will inevitably be contaminated with mold release agents and other dirt and burn marks after a period of use , The use of liquid spray noise (or shot peening) cleaning, the effect is very significant and can also improve the service life of the mold. The use of liquid spray (pills) for food molds can meet the medical sterilization requirements.

Renovation of old mechanical parts can achieve the effect of looking like new. Voltage resistance of ceramic components in the electronics industry.

(5) Prepare for other surface treatment processes

The parts are treated with liquid spray before electroplating, and the electroplating layer has strong adhesion. This is especially true for hard chrome plating. For example, the engine piston ring is chrome plated, and the textile machine idler roller is plated with pear surface chrome, etc.

Paint parts, spray parts. The use of liquid spray before spraying can increase the adhesion of the coating. The bonding parts are of good quality and firmness by liquid spraying.

(6) Finishing

Liquid blasting (shot) sand is very effective as a finishing method. Especially for parts with complex shapes, such as impeller engine blades, various mold surfaces such as currency molds, and the polishing of commemorative coin molds, it is unmatched by any other method. Polish ceramics and diamonds with liquid spray. is a very economical method. Such as the polishing of chemical fiber textile machinery friction wheel.

(7) In order to obtain a decorative surface without reflected light

The surface processed with liquid spray or spray (pellet) is not reflective. For parts that need to have a smooth surface and are not allowed to reflect light, it is an effective process to use liquid spray or noise shot. such as surgical instruments.

Others such as grinding glassware and patterns, instrument panel, processing of sand surface of plastic drawing paper, mirror surface of monocrystalline silicon surface, and plush processing of special fabrics etc., liquid spray noise has a wide range of applications.