Products Center

Tel:+86-769-82261696

Dongguan Meijun sandblasting equipment professional production: full-featured wet water sandblasting machine

High pressure water sandblasting machine-Meijun type I machine

Type I machine: siphon negative pressure water sandblasting machine, negative pressure water sandblasting room, stainless steel water sandblasting series

Type II machine: high-pressure water sandblasting machine, high-pressure water sandblasting machine room, rust removal, paint removal, and oxide layer cleaning series

Type III machine: high-pressure water jet sandblasting, high-speed cleaning water sandblasting machine for steel coil and steel plate, rust removal, paint removal and oxide layer cleaning series

High pressure water sandblasting machine, high pressure water sandblasting machine room

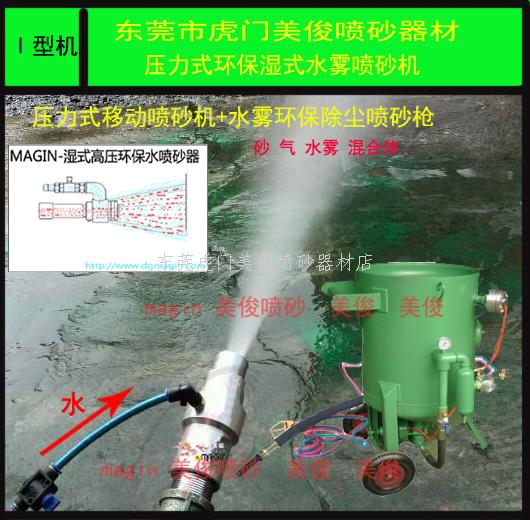

Type I high pressure water blasting machine:

Dry pressure feeding sandblasting machine + environmental protection dust removal water mist sandblasting gun

Features: dry sand in the jar, dry sand in the sand tube, only after the gun is mixed with water mist, it does not affect the installation speed of sand abrasives, and the efficiency is high. The disadvantage is that the sand sprayed out is wet,

After recycling, it needs to be dried before it can be used in cans, so this machine is suitable for outdoor use of disposable low-cost abrasives (such as river sand, quartz sand, copper ore sand) for sandblasting.

The pressure-feeding mobile sandblasting machine of Dongguan Meijun Sandblasting Equipment adopts the pressure-relieving pneumatic control mode. The characteristics of this machine are:

1) One person can operate one machine, and can control the startup and shutdown independently, saving manpower;

2) Pneumatic control, linkage exhaust, pressure relief, so that the air pressure of the sandblasting tank is 0, and the pressure during startup operation does not exceed 6 kg, which is far away from the design pressure of the sandblasting tank, thus changing the safety of the pressurization.

It is a safe pressure-feeding high-pressure sandblasting machine;

3) The technology of instantaneous exhaust after shutdown is adopted, which can ensure that the residual air pressure in the tank will continue to press the abrasive into the sand pipe, causing sand blocking when starting again. At the same time, due to the application of the manual switch, the operator can

Controlled by hand, the startup and blasting can be carried out at the same time, effectively controlling the mixing ratio of high-pressure air and abrasive in the sand pipe, reducing the pulse phenomenon, and making blasting very smooth.

Due to the above technical characteristics, the pressure-feeding sandblasting machine of Meijun sandblasting equipment is especially suitable for long-term sandblasting processing of engineering, and sandblasting of extended pipelines (50m/80m/100m).

People can operate a machine, turn it on and off at any time, and control it by themselves, which not only saves manpower, but also has the convenience and safety of independent control. It is the first choice for sandblasting construction.

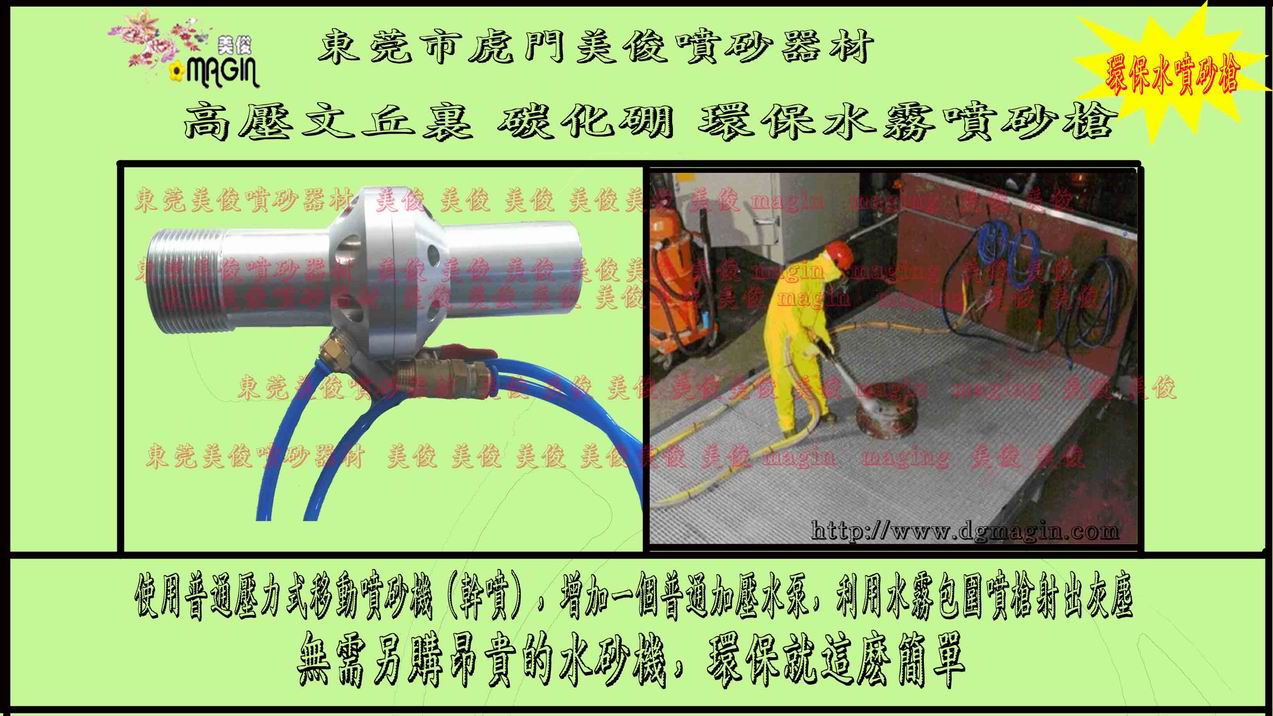

Dongguan Meijun high-pressure water sandblasting machine type I sandblasting system: It is a mobile combined sandblasting treatment method with a pressure mobile sandblasting machine as the main working system and atomized water as an auxiliary dust reduction. water blasting,

A cost-saving and effective way of environmentally friendly dust-free sandblasting.

Widely used in sandblasting and three-dimensional carving of glass, marble and other stone materials, sandblasting in shipbuilding, surface treatment of steel structures such as bridges, railways, containers, and petrochemical facilities before painting, rust removal

Anti-corrosion treatment has the advantages of dust-free environmental protection and no air pollution. It can be constructed in any occasion without considering the pollution and interference caused by dust to the surrounding environment. It is an increasingly popular outdoor sandblasting construction mode..

The pressure-feed high-pressure water blasting system actually consists of two parts:

1) Sandblasting main system: using standard dry pressure mobile sandblasting machine system.

2)Dust removal system: The tap water water supply system with a slight pressure source is mixed with the abrasive sprayed at high speed after being treated by the water mist sandblasting gun to achieve the purpose of removing dust.

一:Sandblasting system

Pressure feed type high pressure water blasting system:

The main sandblasting system is a pressure-type mobile sandblasting machine, which is a thermal spraying pre-treatment machine. It is powered by compressed air and sprays clean and dry abrasives on the surface of the workpiece to be sprayed at high speed to achieve surface cleaning,

It can also be used to remove paint, remove rust from welds, prepare frosted glass and other workpieces, and the effect is very significant. The cleaning level reaches SA2.5-3.0, and its roughness meets the process requirements. Products

It has the characteristics of wide application, compact structure, simple maintenance and convenient use. It is a necessary machine for thermal spraying (welding) various anti-corrosion layers.

The sandblasting host is a pressure mobile sandblasting machine with self-exhaust pressure relief

Main indicators of pressure relief type: install the automatic exhaust valve, install the intake valve at the front of the air inlet, stop the machine at 0 air pressure, press the switch, the sand tank starts to inflate, pressurize, and the sandblasting starts synchronously.

Since the pressure relief type starts to inflate and pressurize the sand tank after the switch is pressed, the sandblasting machine has already started sandblasting at the same time as the pressurization. At this time, the air pressure in the tank can never be higher than the supply of the air compressor. gas

pressure (8KG), and the pressure in the tank will be quickly drained after the shutdown, so the pressure relief type sandblasting machine has the characteristics of safety and reliability, and there is no need to worry about the pressure value at all. It is a very reliable pressure-feeding sandblasting machine.

At the same time, due to the characteristics of the pressure relief type sandblasting machine that starts up and works, this requires the air compressor that provides compressed air to have a large flow rate to ensure the instantaneous pressure of the sandblasting machine when it is turned on and the subsequent

Flow requirements, higher requirements for air compressors.

(Features: The sandblasting machine operates automatically for each operation, and it is operated by one person, which is simple and convenient. After each operation is completed, the air control switch is released, and the sand cylinder is automatically exhausted, which is safe and reliable, and the pressure relief can reduce the phenomenon of sand blocking.)

The pneumatic remote control system of the pressure relief pressure mobile sandblasting machine is composed of an intake valve, an automatic exhaust valve, a control air pipe, a manual control switch and a pneumatic control sand control valve (manual sand valve).

Work process description:

When working, press down the handle of the manual control switch, and control the air flow through a trachea (red) (out from the A port on the cut-off valve) to the manual switch, and through another trachea (blue) to the air inlet on the cut-off valve ( B port),

In this way, the intake valve of the main pipeline in the stop valve is opened, and the air source channel entering the sand cylinder and the cylinder side air supply pipe is opened. Air valve and

(or) Sand control valve, the sand control valve is opened - the exhaust valve is closed, at this time, the mushroom head on the top of the sand tank is flushed, the tank is sealed, the pressure in the tank is increased, and the sand blasting operation begins.

The characteristics of this model are that every time the switch, the air shut-off valve (intake valve), the automatic exhaust valve, the air-controlled sand control valve (the manual sand valve is normally open), these three valves must be activated, and the gas in the sandblasting cylinder must be activated. will increase and

discharge, and each switch has a certain time, so the operator can put down the spray gun only after all the gas in the sandblasting cylinder is discharged.

一、System parameters of this model:

1、Main technical parameters and structure of the equipment

1)The main technical parameters

|

Cylinder straight径:600mm Sandblasting efficiency: 15-35 square meters/H |

|

Cylinder heightSpend:1300mm Sandblasting grade:SA2.5-3.0 |

|

Allow Product: 0.3-0.6 cubic Air consumption: ≥3立方/min |

|

Use air pressure: 0.6-0.7Mpa 功率:35HP Use air pressure: 0.6-0.7Mpa(8KG) Must not exceed 8KG pressure |

|

Large tube: 35HP (8MM muzzle)-50HP (10MM muzzle)-75HP (12MM muzzle) Small tube: above 20HP |

|

design pressure:8.8KG experimental pressure:1.15MPA(11.5KG) Features: low failure rate, less wearing parts, less investment, high efficiency, combined with mobile and fixed knots, can be used in fixed-point sandblasting rooms, and can also be used outdoors. |

2Advantages of this machine:

1.Compact structure, superior performance, simple and convenient operation;

2.The design and production of the cylinder body conform to the pressure vessel standard, which is safe and reliable.

3.Using standard general parts, easy to replace, lower cost, especially the separation of wear parts and fixed parts, and the addition of wear parts in the middle, effectively reducing the cost of replacement loss;

4.It can be modified and installed at any time with instant control function, using electric control or pneumatic control to meet the different needs of customers, and can be operated by a single person.

5.The shell is thickened and sprayed with anti-rust paint, which is beautiful and practical. .

3Abrasive particle requirements:

Sand for sandblasting and rust removal requires hard particles, angular, dry and free of soil and other impurities; the standard is brown corundum particle size sand, and quartz sand is better for economical benefits, and coarse river sand is also acceptable.;

At the same time, factors such as sand transportation conditions, unit price, recycling capacity, etc. should be considered; the particle size of sand should be 0.5-1.5mm, it must be dried before screening, and stored in sheds or indoors with large sieve holes.

Small: coarse sieve 40-48 holes (particle size 1.2mm), fine sieve 372-476 holes (particle size 0.3mm)

When adding sand to the sand tank, the top of the tank should be covered with a screen of 16# or more to screen the sand particles to prevent foreign matter from falling into the tank and causing blockage of the sand valve or nozzle.

4Air source requirements:

|

Use air source pressure: 0.6-0.7Mpa (8KG) must not exceed 8KG pressure |

Power comparison: 35HP(using 8MM nozzle)/50HP (using 10MM nozzle)/75HP (using 12MM nozzle)

Compressed air must be processed by cooling device and oil-water separator to ensure dry and oil-free;

The oil-water separator must be cleaned regularly;

Generally, the air pressure of the air compressor is 6.0×105~6.5×105Pa, and the pressure variation is0.5×105~1.0×105Pa。

Generally, the air pressure of the sand bucket is 4.5×105~5.5×105Pa, not less than4.0×105Pa。

If the pressure of the sand tank exceeds 0.7MPA, please stop the gas supply, and exhaust the gas in the tank, check the cause and deal with it.

二、use

1、Prepare

Requirements for working protection before use of rust blasting machine:

Inspection - The non-blasted parts should be shielded and protected before blasting.

Check - before sandblasting, whether the various pipes and control valves of the sandblasting machine are well connected, and whether they are in the appropriate switch positions - the sand adjustment valve (8) and the intake valve (4) must be in a closed state, and the exhaust valve (17) must be in a closed state. ) is closed.

Check - whether the protective tools, safety belts (ropes) and oxygen supply devices worn by the blaster are safe and reliable, and the wear of the nozzles (when the orifice

The nozzle should be replaced when the diameter increases by 25%)。

Connect each connection road and all pipelines according to the diagram, and check whether they are firm and sealed.

Check - whether the pneumatic control system is normal and whether the manual switch is normal.

Check - the exhaust valve is closed.

1)Use an air hose to connect the sandblasting machine to the air source, and tighten it correctly (use a special joint to connect and fix it, and add iron wire to pull the air tube) to prevent the tube from falling off..

2)Connect the sandblasting pipe to the quick connector at the outlet end of the abrasive valve, and lock it (lock the hole with a screw after the dragon grip is docked) to prevent the sand pipe from falling off during use, resulting in accidental danger.

3)Load clean, dry abrasive into the blaster bucket. (It is easy to add sand in 2/3 of the sand tank)

4)Start the air compressor to make the indicated pressure reach the required working pressure. The air compressor is placed on the upper air outlet of the sandblasting machine to prevent the dust caused by sandblasting from being sucked into the air compressor..

5)Wear sandblasting protective equipment。

2、Operation control of rust blasting machine for steel structure:

1)First turn off the side trachea ball valve switch (4A), and close the tank bottom sand control valve or ball valve (8) at the same time, and the sandblaster holds the sandblasting gun to prepare for work.

2)Turn on the air source of the air compressor, open the switch (4) of the air inlet valve, the air source of the air inlet valve is connected, and the air in the cylinder starts;

Please observe the pressure gauge. The normal pressure value is in the range of 4-6MPA. If the pressure of the pressure gauge is too large and exceeds 7MPA, please stop the gas supply and drain the gas in the tank. Check the cause of the excessive pressure value.

Contact the supplier (air compressor or sandblasting machine) to inquire about related matters;

3)After ventilation, high-pressure air enters the sand cylinder, pressurizes the cylinder, the umbrella-shaped sealing valve on the top automatically lifts up to seal the feed port, the pressure in the sandblasting machine continues to rise, and the sandblasting gun can automatically enter to prepare for sandblasting.

At this time, the sandblaster should hold the spray gun tightly and be ready for sandblasting at any time.

4)Turn on the side trachea ball valve switch (4A), air comes out from the spray gun, then open the sand valve ball valve (8) at the bottom of the sand tank, and the sand blasting starts。

During the sandblasting operation, according to the sandblasting state, adjust the handle on the abrasive valve (sand valve ball valve 8 at the bottom of the sand tank) to adjust the size of the abrasive outlet flow (close in the horizontal direction, close in the vertical direction).

The direction is fully open), the flow of abrasive should not be too large, and observed under the sun or other bright light sources, the air flow containing abrasive is not much different from the pure air flow。

5) At the end of the job, the blaster still needs to hold the gun tightly, and another assists the blaster to shut down the machine。

Close the ball valve switch (4) --- close the sand valve ball valve (8) at the bottom of the sand tank --- close the side trachea ball valve switch (4A) More information about this original text To view additional translation information, you must enter the corresponding original text send

At this time, the sandblasting gun slowly and automatically stops the sandblasting work. The sandblaster needs to wait for the residual sand and air in the sand pipe to be exhausted before putting down the gun to ensure safety.。

After all the processes are completed, there is still high-pressure gas in the sand tank. After a short pause, you can continue with steps 1)-4) for sandblasting. If you need to stop, you need to manually open the exhaust on the top side of the sand tank

The ball valve (17) is used to discharge the gas in the cylinder.

Sandblasting distance: The distance between the gun and the surface of the base steel during sandblasting is preferably 100-300mm.

Sandblasting angle: the angle between the spraying direction and the normal to the surface of the base steel is preferably 15° to 45°.

After sandblasting and rust removal, before proceeding to the next process, in case of rain or other conditions that cause the surface of the base steel to be wet, dry the surface with dry compressed air after the environment reaches the construction conditions.

After the surface moisture, sandblasting construction is carried out. If it is necessary to re-blast, the abrasive requirements cannot be reduced, so as not to reduce the roughness and cause low adhesion of subsequent spraying.

After the blasting operation is completed, turn off the main air source of the air compressor, stop supplying air to the air compressor, open the air compressor exhaust valve, and discharge the residual gas in the air compressor. Turn off the power and turn off the air compressor。

If the sandblasting machine is not used for a long time, it is necessary to clean the remaining abrasive in the cylinder to prevent wet agglomeration or sand blocking.

三、downtime

When the sandblasting machine needs to be shut down for a long time, the abrasive in the barrel should be clean to prevent the abrasive from being damaged due to moisture when it is reused. The steps for cleaning the abrasive are:

1、Remove the nozzle。

2、Place the blast hose in a container。

3、Close the side air valve (4a) and exhaust valve (17) and open the abrasive valve to the maximum。

4、Open the intake valve (4) and let the sandblasting machine work until the excess abrasive in the cylinder is completely drained, and finally open the side air valve (4a) to blow out the abrasive in the sand pipe.

When the sandblaster is placed outdoors at night, it should be covered to prevent water from entering the bucket.

四、Maintenance

1、Replace the closing valve (umbrella bucket)

Open the access valve, use a small pipe wrench to unscrew the connections (conduit) under the conical closure valve (umbrella bucket), and remove them from the bucket. After replacing with a new closing valve, install it as it is.

Install the inspection hole cover and tighten all screws.

2、Replace the inlet seal

Gently remove the old seal with a fingernail or screwdriver, then press the new seal into the sealing seat。

3、Regularly check the lubrication and wear of the O-rings, pistons, springs, gaskets and other parts in the intake valve (air shut-off valve) and exhaust valve.

五、troubleshooting

1、blockage

1)There is neither abrasive nor air at the nozzle outlet

Close the intake valve (4), open the exhaust valve (17), and after the blasting machine is depressurized, check whether the nozzle is blocked, if the blockage needs to be cleaned, you can continue blasting;

2)With air without abrasive

If the nozzle is not blocked, it may be blocked at the sand adjusting valve or the sand port under the tank bottom. It is necessary to disassemble the sand valve to check, discharge foreign matter, and continue sand blasting after reinstalling the sand valve..

Open the abrasive valve to the maximum limit, open it quickly and then close the main intake valve (4) immediately, then quickly open the main intake valve (4), cycle for many times, and use the pulse force to impact the blockage.

If this method does not work, it is necessary to disassemble and check whether the sand control valve is blocked. If the problem cannot be solved, open the inspection hole (15) to remove the debris in the barrel and remove the blockage in the abrasive valve.。

2、Unstable blasting: It is normal for the abrasive flow to be slightly unstable. If the abrasive flow continues to be unstable, open the side air valve (4a) quickly and then close the side air valve (4a) or close the side air valve (4a) small.

Eliminate this fault, and at the same time, you can adjust the switch of the small side air valve (4a) according to the needs, close it small to reduce the airflow, etc., and adjust it to a certain extent to eliminate the instability phenomenon.

3、Remove damp abrasive

Ensure that there is no one or a rebounding object in front of the abrasive valve. On the premise of closing the abrasive valve, remove the sandblasting hose and the corresponding gasket, open the abrasive valve (8) and the intake valve (4), and close it back and forth.

Open the side inlet valve (4a), the wet abrasive can be removed.

(Note: The inlet speed of abrasive is very high, and irrelevant personnel must stay away from the inlet of the abrasive valve).

Then close the intake valve (4), open the exhaust valve (17), then connect the blasting hose with the nozzle removed to the blasting machine, open the intake valve (4) and the side air valve (4a), and spray Wet inside sand hose

Abrasives are also removed. Close the exhaust valve (17), then connect the nozzle to the sandblasting hose, and the sandblasting operation can be resumed as normal.。

4、Exhaust valve does not exhaust or exhaust slowly

1)cleaning

2)Replace the exhaust valve.

六:Precautions

1) The abrasive used must be dry and screened and free of impurities.

2) The abrasive can only be added to four-fifths of the volume of the tank and cannot be filled.

3) When the umbrella-shaped automatic closing valve (mushroom head) does not move up and down flexibly, please do not introduce abrasives, and it should be repaired or replaced.

It should be replaced once to prevent aging and unsealing).

4) After all the abrasives have entered the tank, use a dust blowing gun or broom to clean the mushroom head. Only after all the sand has entered the tank can the air valve be opened to supply air to prevent the sand from wearing the O-ring and the mushroom head.

5) During the operation, the sandblasting is interrupted due to the fault. Do not hit the tank or spray gun with a hammer, wrench or other heavy and hard objects. Other corresponding measures should be taken to deal with and clean up, and the operation should be stopped.

After removing the pressure of the tank body, it can be disposed of.

6) When the sandblasting pipe is under pressure and high pressure, it cannot move, knock, insert and pull out the gas pipe and spray gun at will, otherwise it will cause danger and cause an accident.

7) Because the abrasive has a certain distance from the sandblasting pipe to the nozzle, it takes a certain time to be ejected from the nozzle. Therefore, when adjusting the sand volume of the sand valve, the frequency of adjusting the handle should be

Slower, adjust while observing (sand adjustment valve spray gun can not be aimed at people and things).

8) It is said that the compressed air used must be difficult to filter, filter out the compressed air of moisture and oil mist, and ensure a good pressure, and the pressure cannot exceed 8KG/square(0.7MPa).

9) Never use abrasives with a grit diameter larger than 1/3 the diameter of the nozzle used.

10)For sandblasting, it is forbidden to point the nozzle at people, and no one can stand beside them..

11)Reasonable selection of nozzles of different diameters according to the flow of the air compressor, should be replaced after the wear of the nozzle diameter increases (generally more than 1.5MM).

The relationship between nozzle diameter and air compressor flow

|

Nozzle diameter |

|

effective pressure(MPa) |

cleaning efficiencym2/h (Sa2.5—Sa3.0) |

||

|

0.5 |

0.6 |

0.7 |

|||

|

6.5mm |

air consumption(m3/min) |

1.6 |

1.9 |

2.1 |

6—11 |

|

Abrasive consumption (Kg/h) |

170 |

200 |

240 |

||

|

8mm |

air consumption(m3/min) |

2.9 |

3.5 |

3.9 |

10—20 |

|

Abrasive consumption(Kg/h) |

280 |

340 |

380 |

||

|

10mm |

air consumption(m3/min) |

5.4 |

6.5 |

7 |

16—30 |

|

Abrasive consumption(Kg/h) |

500 |

600 |

680 |

||

二: Dust removal system

The dust removal system is mainly completed by a water mist sandblasting gun connected to a pressurized water pipe: