Products Center

Tel:+86-769-82261696

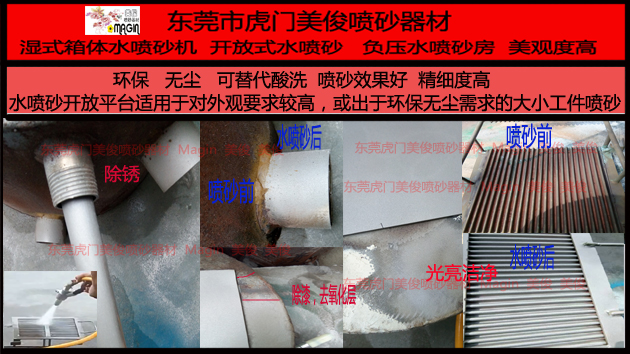

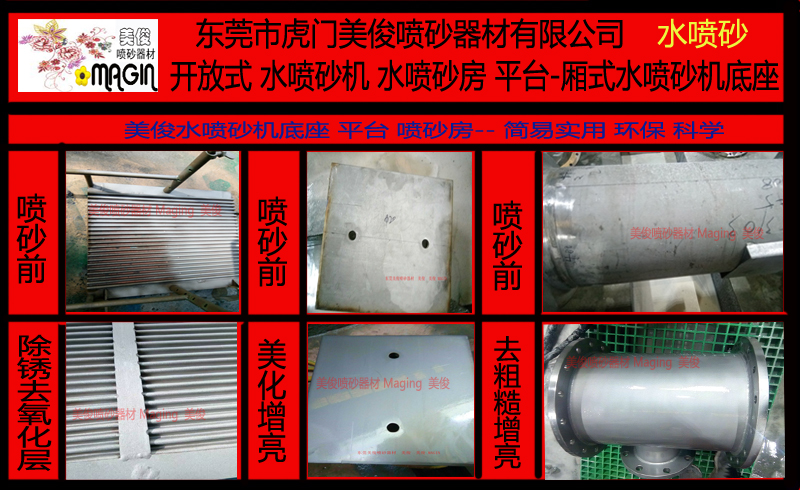

water sandblasting machine, wet sandblasting machine, environmental protection water sandblasting machine, negative pressure water sandblasting machine

7.5KW open liquid water sandblasting machine/room platform

I.Overview

(1) Purpose

This machine is a new type of equipment that uses grinding fluid pump and compressed air as power to perform grinding fluid jet finishing on workpieces.

This machine can clean the rough surface, oxide skin, residual salt and burrs of forging and casting blanks, welded parts, heat-treated parts, stamping parts and machined parts. It can be used for pre-coating and plating, and can be used for sandblasting of parts with high precision, high luminosity, and complex shapes that are difficult to achieve by other processing methods. It is suitable for the renovation of old parts.

This machine can also be used as liquid shot blasting (glass shot) to strengthen the surface of parts.

(2) Features

1. No dust is generated during work, which reduces the pollution of dust to the environment and the harm to workers' health.

2. The working method is flexible and the process parameters are variable, which can adapt to the processing requirements of different materials and different precision parts.

3. The quality of the processed surface is high. Under the condition of reasonable selection of process parameters, the roughness after spraying is generally higher than that before spraying.

The roughness is one level, and the surface of the parts after sandblasting is hardened, which can improve the wear resistance and fatigue strength of the parts.

4. The abrasive is recycled and the consumption is small.

5. The main components have a long service life and are easy to maintain.

(3) Composition

This machine is composed of the main body, grinding liquid pump, spray gun, electrical control, etc. It is used to complete the basic operation and auxiliary work of liquid sandblasting.

(4) Main technical data

1) The cross-sectional area of the storage tank: the standard setting is 1100*1100MM (optional), on the basis of the main bucket, the steel plate and the frame are spliced upwards and outwards, the operation platform is enlarged, and protective plates are added around to form the corresponding operation platform or sandblasting room. .

2) The motor power of the grinding fluid pump is 7.5KW;

3) Abrasives with various particle sizes from 46# to 120#;

4) 1-3 manual boron carbide sandblasting guns, nozzle diameter Æ6-12mm;

5) The compressed air source pressure is 0.5~0.7MPa;

6) The compressed air consumption of a single gun is about 1-1.5 m3/min;

7)The water source is industrial tap water.

2. Working principle

(1) Host system

This machine is the basic device for liquid sandblasting. The basic principle of grinding fluid jet machining is to use the grinding fluid pump and compressed air as the driving force to spray the grinding fluid onto the surface of the workpiece at a high speed through the spray gun to achieve the purpose of sandblasting. The grinding fluid is made by mixing clear water mixed with "decoration retarder" and abrasives of a certain particle size in a certain proportion.

The sandblasting operation is carried out on the upper working platform of the machine body (that is, the section of the storage tank) (on the basis of the main bucket, the steel plate and the skeleton are spliced upwards and outwards, the operation platform is enlarged, and protective plates are added around it. The corresponding operating platform or sandblasting room will be formed). The spray gun is the main component that directly performs the liquid sandblasting work, and it is connected with the two pipeline systems of grinding fluid and compressed air. When working, the grinding fluid pump sends the grinding fluid in the tank of the machine body to the spray gun through the grinding fluid pipeline at a certain pressure and flow rate. , so that the abrasive and water in the tank are evenly stirred, so that the abrasive pump can work effectively. Compressed air enters the spray gun from an external air source through a solenoid valve. Through the working mode of air-pump, the ejected air-grinding fluid flow can have a large speed, so the processing efficiency is high. Select the appropriate particle size abrasive, grinding fluid concentration ratio, spray angle and spray distance and other process parameters, the specified sandblasting process can be completed. The sprayed grinding fluid is returned to the storage tank through the grid plate, and the processing of the workpiece is completed in this cycle.

(2) Sand collection system (optional - used by sandblasting machine, not suitable for sandblasting room)

The sand collector is a device used to concentrate the grinding fluid and collect the abrasive. The device can be activated in the following two situations: First, when the process requires frequent replacement of abrasive varieties and different specifications, the original abrasive is collected for reuse to reduce abrasive waste; second, after the grinding fluid has been used for a period of time, the broken abrasives increase, which affects the The surface effect of sandblasting products should be replaced with new abrasives.

For example, aluminum alloy is blasted with glass beads, and the spray effect is different after the glass beads are broken. If all the broken glass beads need to be replaced by the grinding fluid, they need to be collected by a sand collection system, or they can be directly discharged into the sewer, but it will waste grinding. At the same time, the grinding liquid is directly discharged into the trench, which will lead to sewer blockage in the long run. At this time, the sand collector can be used to collect the waste abrasive and then centrally treat it so that it does not flow into the sewer.

When the sand collector is activated, the normally closed "separation valve" should be opened, and if the grinding fluid pumped by the host machine is pumped, there will be a tangential liquid inlet pipe that flows to the cyclone through the valve. And then injected into the cyclone at high speed. Due to the constraints of the cone, the specific gravity of abrasive and water in the grinding fluid is different, the centrifugal force is also different and other factors, the concentration of the outer grinding fluid is bound to increase, and it will spirally sink to the lower end of the cone. The water is in the axial center of the cyclone and is subjected to upward force, flows out from the water outlet at the top of the cyclone, and flows back into the main engine storage tank along the conduit.

In this way, after starting the grinding liquid pump for a few minutes, the grinding liquid pump is stopped, and the sand discharge valve of the sand accumulating tank is opened, and the concentrated abrasive slurry can be collected in the container. Most of the abrasives in the grinding fluid can be collected for the first time, and after 2 to 3 cycles, the abrasives in the grinding fluid can be collected (the sand collection rate is over 90%, except for the abrasives that do not participate in the grinding fluid circulation at the dead corners) . After the collection is completed, the dispensing valve and the sand outlet valve must be closed.

(3) Settling box (optional by the user, used for workpieces with a lot of impurities in the sandblasting waste liquid, generally not required in the sandblasting room)

The body sandblasting bucket is recycled to prevent the loss of grinding fluid.

3. Electrical system

(1) Main technical data

1. Electrical equipment

1) Milling fluid pump motor: AC380V, 50Hz, 7.5KW.

2) Total power: about 7.5KW.

3) Electric control box: one set (including control part)

2. Abrasive:

1) Type: Corundum abrasive is recommended, and other abrasives are also allowed.

2) Granularity: corundum abrasives with various particle sizes between 46# and 120# and glass pellets below 0.3mm.

3) Dosage: weight ratio 1:5~1:7 (dry abrasive : water).

3. Spray gun:

1)Quantity: 1-3 boron carbide blasting guns (manual). (5 meters for sandblasting hose, 5 meters for air pipe)

2) Nozzle diameter: Φ6-12.5 mm.

3) Air nozzle diameter: Φ3-6.5 mm.

4) Working pressure (compressed air gauge pressure after startup): 0.5~0.7Mpa.

5)Single gun air consumption: about 1~1.5m3/min (determined according to the compressed air pressure).

4. Working conditions:

1) Power supply: AC380V, 50Hz.

2) Compressed air source: the air source pressure is 0.8~1MPa, and the displacement is not less than 7.5M3/min [referring to the air volume flow in the standard state (200C, 101.325kPa)]. According to the needs, the steel pipe can be pre-embedded, and the hard pipe can be used to connect the air circuit of the host; it can also be connected to the host with an air hose with an inner diameter of Φ25mm and a working pressure of 0.8Mpa.

3) Water source: industrial tap water. According to the needs, the steel pipe can be pre-buried, and the main machine waterway can be connected with the industrial tap water source with a hard pipe; it can also be connected with a water delivery hose with an inner diameter of Φ13mm.