Products Center

Tel:+86-769-82261696

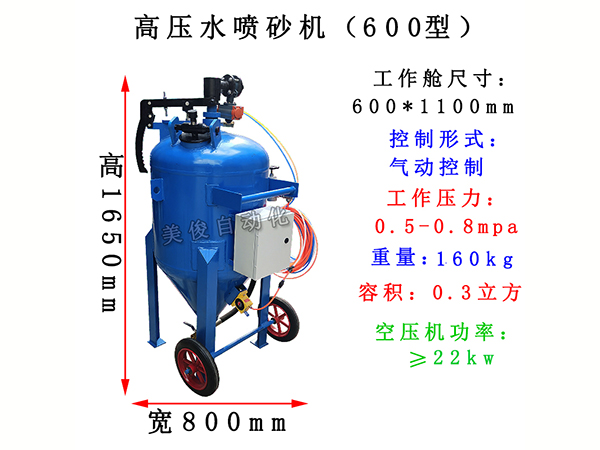

Environmental dust-free sandblasting machine, high-pressure water sandblasting machine II water sand blasting machine, high pressure water sand blasting machine

Dongguan Meijun Automation Equipment:

Full-featured wet water sandblasting This is a new type of environmentally friendly dust-free rust removal equipment. After sandblasting, the product cleanliness can reach (sa2.5-3.0 level)

Meijun sandblasting equipment is the earliest A group of manufacturers of sandblasting machines and sandblasting machine accessories, with fifteen years of brand growth history.

Specializing in the production of wet general pressure and high pressure, ultra-high pressure water sandblasting machine---focus on surface treatment for 15 years.

Environmental protection issues have become the focus of attention in the world today, especially the surface treatment environmental protection issues in our manufacturing industry. It is not an occasional thing to stop production, stop work, and close doors to meet environmental protection requirements. It has already been related to the survival of the manufacturing industry.

The tide of economic globalization and the call to solve global environmental problems have made the relationship between environment and trade increasingly close. International organizations have formulated a series of technical standards aimed at protecting the environment. How to prevent air pollution and clean the air environment is also a subject of continuous research. Although my country has entered the ranks of the world's manufacturing powers, it is closely followed by the pollution of the atmospheric environment. The fine dust in the air is very harmful to human health. It is not only deposited in the lungs, but can also directly enter the bloodstream and reach various parts of the human body. There are also various toxic substances attached to the surface of dust particles. Once it enters the human body, it will cause various respiratory diseases, and the harm will be even greater. Therefore, controlling the emission of dust is an important measure to control air pollution and clean the air environment in my country.

In addition, electronics, precision instrument processing, and other major manufacturing industries have higher requirements for dust content in the air, and generally require a dust removal efficiency of more than 99.7% for sub-micron dust. Dust emission is harmful to the environment and human body, so we mainly introduce wet water sandblasting without dust pollution to meet the requirements of environmental protection production.

Type II machine: high-pressure water sandblasting machine, high-pressure water sandblasting machine room, rust removal, paint removal and oxide layer cleaning series

The features of this machine are:

Water and abrasive are mixed in the sandblasting tank, and then high-pressure air is introduced as power to form a water-air-sand mixture, which is then sprayed out through a sandblasting pipe through a sandblasting gun, and the abrasive is sprayed out and recovered. It can be directly put into the sand tank and used again with water, so the type II machine can be used as an ideal water sandblasting machine for high-pressure water sandblasting + sandblasting room;

Namely: Type II pressure water sandblasting machine + O type negative pressure water sanding platform = water sandblasting room

Water blasting machine manufacturer environmental protection high pressure water Sand derusting equipment high-pressure water sandblasting machine, dust-free water sandblasting machine, environmental protection sandblasting machine, rust-removing sandblasting machine

Environmentally friendly high pressure water blasting machine water blasting equipment

Water rust sandblasting machineWater sandblasting equipment Environmental sandblasting machine

1 Overview:

1.1 Purpose:

This machine is a press-in working system formed by compressed air, and uses water and abrasives as the medium for jet processing of parts.

1.1.1 This machine can complete the following work:

1) Clean the oxide scale and welding slag of heat-treated parts, welded parts, castings, forgings, etc., and the cleaning quality can reach Sa3 level;

2) Clean the microburrs, surface residues, etc. of the machined parts;

3) It can be used as a pretreatment process before coating and plating on the surface of the workpiece to obtain an active surface and improve the adhesion of the coating and plating;

4) It can be used to improve the physical and mechanical properties of the workpiece surface, such as changing the surface stress state and improving the lubrication conditions of the mating parts;

5) It is also very suitable for refurbishment of old parts. (cleanliness up to Sa3.0)

Water sandblasting, water sandblasting, water sandblasting, water sandblasting machine

Stainless steel water blasting, metal water blasting

1.1.2 The applicable process of this machine:

Suitable for

water sandblasting and water shot blasting.

1.2 Features:

1) Flexible working methods and variable process parameters;

2) The surface hardening of the parts after sandblasting can improve the wear resistance and fatigue strength of the parts;

3) The main components have a long service life and are easy to maintain.

1.3 Main technical data:

1.3.1 Abrasive:

1) Water: industrial tap water;

2) Water consumption: 120kg for one filling;

3) Types of abrasives: corundum abrasives are recommended, and other abrasives are also allowed;

4) Abrasive particle size: 36# ~ 80#;

5) Abrasive dosage: If corundum abrasive is used, the amount of one filling shall not exceed 130kg;

1.3.2 Sand tank:

Sand tank volume: about 0.3m3; abrasive volume 0.12m3.

1.3.3 Sandblasting hose:

Inner diameter: Ø25mm special sandblasting hose.

1.3.4 Spray gun:

1) Quantity: 1 manual spray gun;

2) Nozzle diameter: φ8mm;

3) Working pressure (compressed air gauge pressure after startup): 0.5~0.7MPa;

4) Air consumption per gun: about 5M3/min.

1.3.5 Air consumption of the whole machine: about 6M3/min.

1.3.6 Dimensions of gas pipe joints: the outer diameter is ¢26.

1.3.7 Working conditions:

Note: Users should prepare the above working conditions when using this machine!

water spray Sand machine stainless steel water sandblasting