Products Center

Tel:+86-769-82261696

1200D Manual Sandblasting Machine Features:

1. Can be manually controlled.

2. It is easy to feed and discharge materials, easy to operate and save manpower.

3. The way of placing and taking the workpiece: This machine is the front door, and the side door is the way of placing and taking.

4. This machine is suitable for manual sandblasting of a small amount of larger workpieces, such as bakelite products, screws, acrylic, plastic products, sleeves, etc.

The use of sandblasting machine

1. Surface removal processing: Oxygen layer of metal or black skin "surface pores" after heat treatment, removal of rust on the surface of metal or non-metal, black spot and color removal or color painting regeneration on ceramic surface, oxidation of rubber mold and gravity die-casting mold Removal of residues or release agents.

2. Surface beautification processing: decorative processing of various metal products and matting and soft matte surface treatment of electroplating products, and non-metallic products: surface atomization treatment of acrylic glass, glass, crystal glass, etc.

3. Hair removal processing: hair removal of plastics, bakelite products, zinc-aluminum die-casting products, etc. and surface finishing of electronic or other parts.

4. Pre-treatment: Electroplating paint, Teflon, PU, rubber and plastic cladding, metal spray welding, titanium plating, etc. before treatment and increase the adhesion of the surface.

5. Etching processing: surface modification and etching processing of precious metal jewelry, gemstones, glass, stone, stone seals, ceramics, wood, etc.

6. Workpiece stress relief processing: parts cleaning and stress relief for aerospace industry parts, or refurbishment and matting, rust removal and paint removal for national defense weapons.

7. Electronic parts processing: removal of impurities on the surface of silicon chips after diffusion, etching and processing of silicon crystals that are cut into small round grains by sandblasting, spraying of overflowing glue burrs in the packaging industry of electronic parts, printing on the surface of finished electronic parts removal, cleaning of ceramic heating materials.

8. Mold processing: pear surface processing (sandblasting) on the surface of the mold, mold bite and matte treatment, increase the adhesion of the mold to the PU, clean and matte surface of the shoe mold, conductive rubber mold, tire mold and electronic product mold deal with. ,

Sandblasting Machine Operation

1. First connect the power supply on the machine to the rated voltage and then power on.

2. Turn the light switch to the right, the light is on, turn left to turn off.

3. Press down the motor switch of the dust collector, the motor starts, and starts to pump and vacuum. At this time, press the foot switch, the solenoid valve can be excited to blast sand, and then step on the foot switch to stop, and so on.

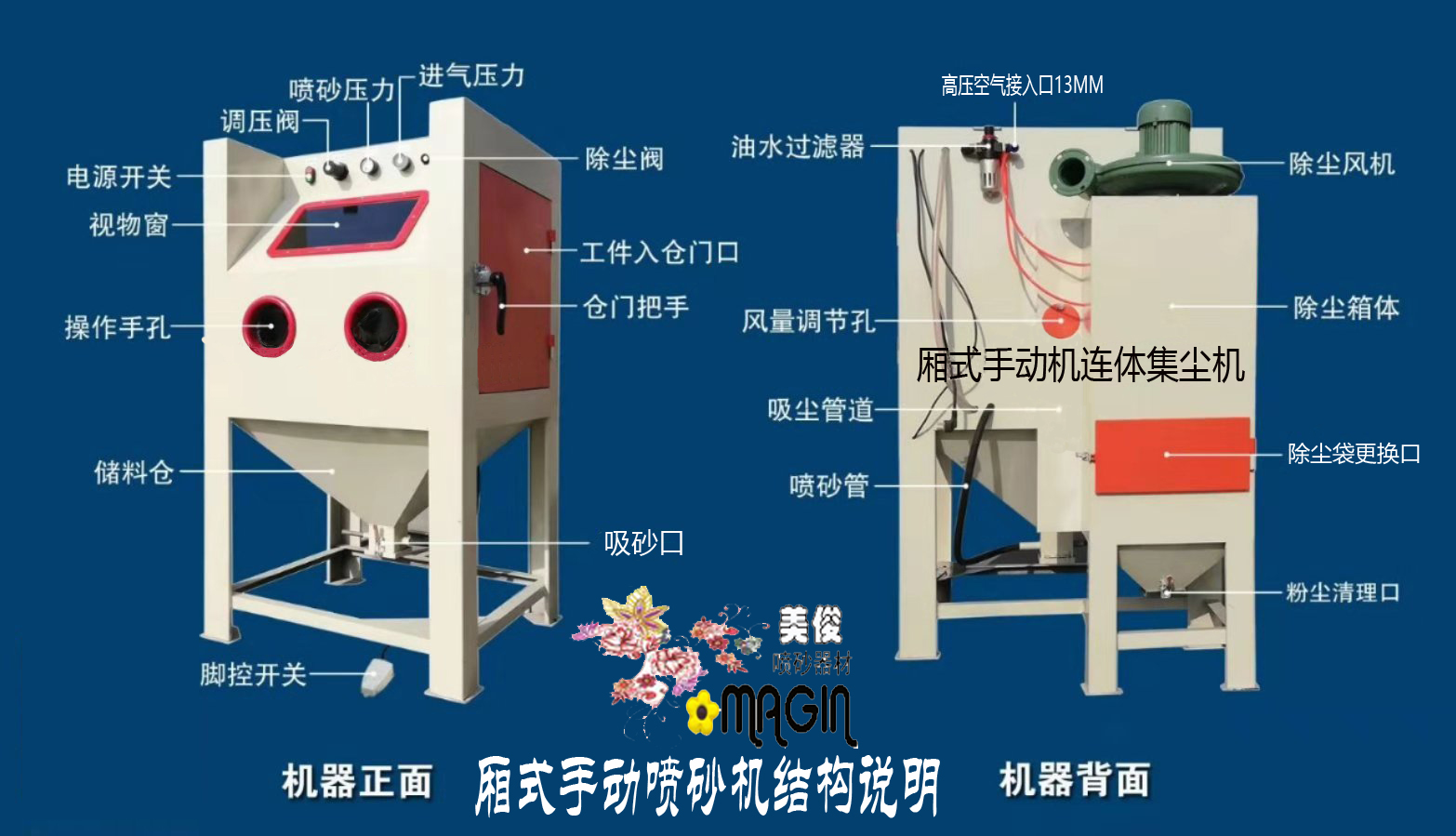

Sandblasting host part:

1. Pressure regulating water filter: It is used to filter the impurity moisture in the air source, so as to avoid damage to the solenoid valve and blockage of the sandblasting gun. It is also used to adjust the air pressure according to the needs of the workpiece product during sandblasting, that is, the difference of the air pressure. The strength is directly related to the speed and impact force of the sand material.

2. Sand discharge rubber stopper: used for emergency sand discharge, or for cleaning when liquid flow in accidentally.

3. Sand release bolt: It is used to remove and separate the sand material in the sand return cylinder. When changing the sand, the sand material can be recovered by a soft bell, and the taper part of the cylinder can be used to speed up the sand leakage action.

4. Sand material recovery cylinder function: It is designed using the principle of centrifugal force and turbulence, and is perfectly applicable.

Main function introduction of dust collector

1. The function of the cloth pipe in the vacuum cleaner is to filter dust, and it can be replaced when it is damaged or blocked.

2. The door of the vacuum cleaner is used to replace the cloth pipe or tap the cloth pipe.

3. The lower part of the vacuum is used to remove dust.

4. The upper door and lower part of the vacuum cleaner should be completely closed when in use, otherwise it will reduce the vacuuming effect or completely fail

5. The cloth tube of the vacuum cleaner needs to be tapped frequently to ensure the smooth suction power. Especially when the suction power of the vacuum cleaner is reduced, be sure to tap to clean the dust collecting cloth tube.

6. The dust in the sand storage tank at the end of the vacuum cleaner needs to be cleaned regularly. It is best to clean it once after a bag of sand is used, so as not to block the cleaning cloth pipe.