Products Center

Tel:+86-769-82261696

|

project name |

1010 Double gun drum automatic sandblasting machine |

|

Specifications |

MaGin-1010-2A |

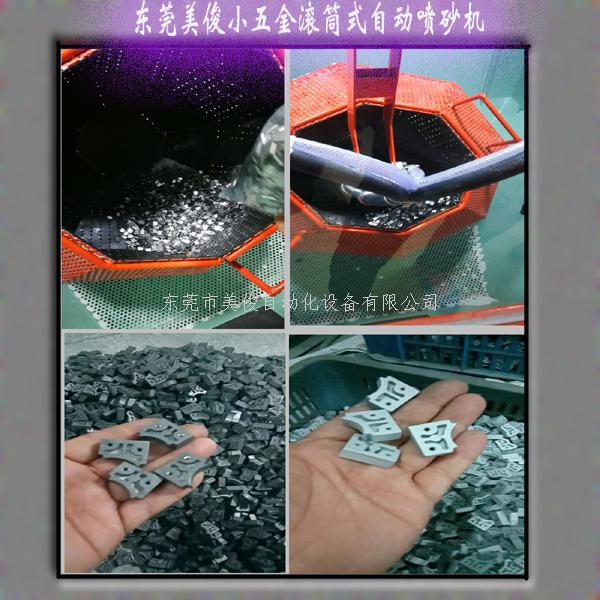

MAGIN-1010-2A Hardware Drum Blast Machine Overview

One: Concept and use of sandblasting machine

Sandblasting machine is a machine that uses compressed air as the power to form a high-speed jet beam to spray the spray material on the surface of the workpiece to be treated at a high speed, so that the mechanical properties of the outer surface of the workpiece surface are changed.

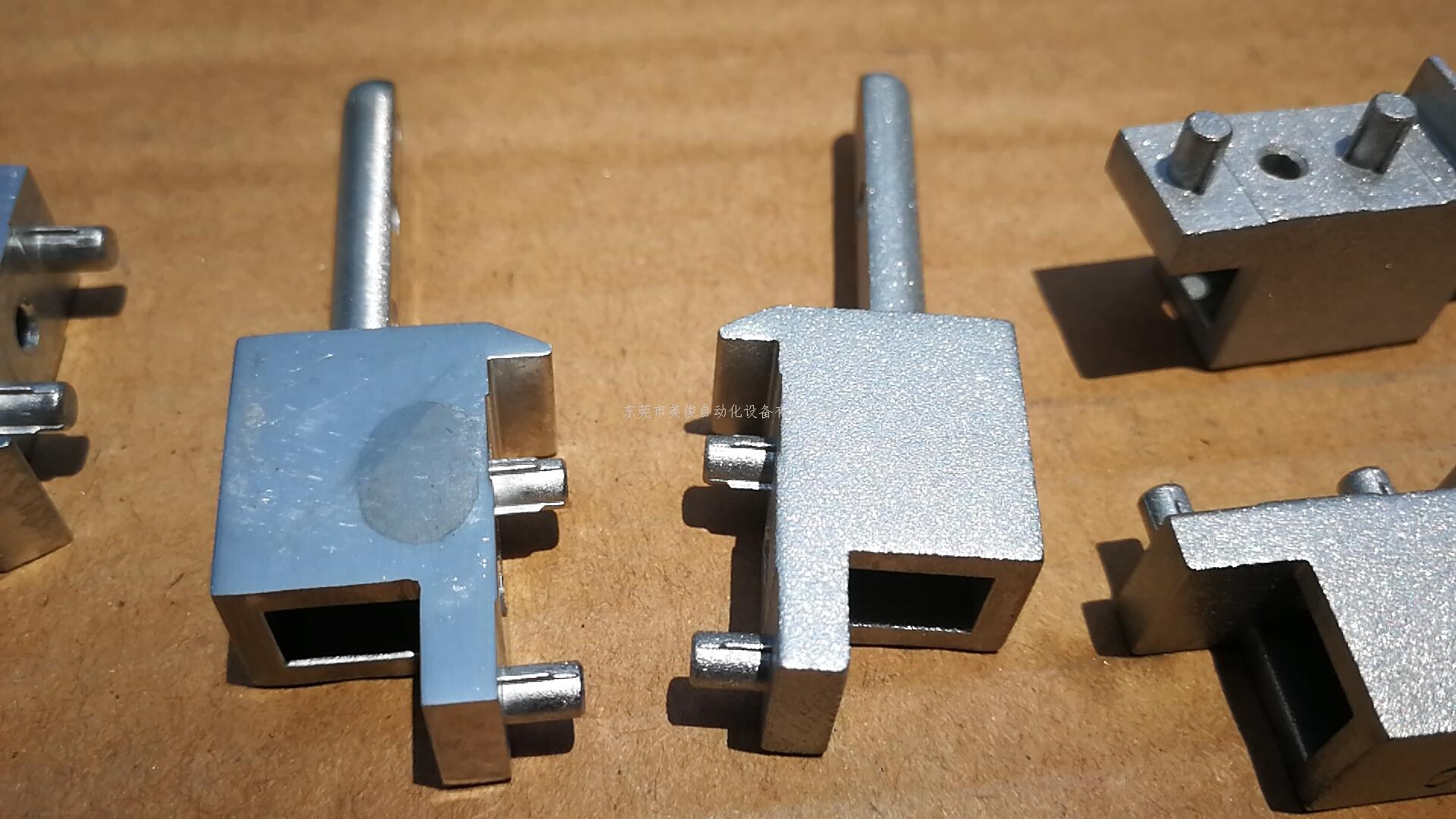

According to the product features provided by customers, this machine is a specially designed double-gun drum type semi-automatic sandblasting machine, which is used for sandblasting the surface of various special-shaped small products. Process requirements such as deburring, oxide skin, surface finishing, electroplating or pretreatment before spraying on the surface of the workpiece.

1.2, working principle

1010-2A drum type automatic sandblasting machine is mainly composed of sandblasting host, drum system, sandblasting system, abrasive recovery system, ventilation and dust removal system, air compression system (customer-prepared) and electronic control system.

The drum type sandblasting machine is powered by compressed air, and through the working pressure of the compressed air, the negative pressure of sandblasting produces traction, so that the abrasive and the compressed air are fully mixed with negative pressure, and the abrasive is pressed into the sand conveying pipe through the sand outlet valve, and then After the acceleration of compressed air, the abrasive is ejected from the nozzle and sprayed onto the surface to be processed to achieve the expected processing purpose. The abrasive circulation system operates in free fall. The abrasive grains with coarser particles are designed not to be sprayed by the fan due to their own weight. The large space in the sand chamber is adsorbed away, and it will fall to the bottom of the sand bucket in a free fall motion and be recycled for reuse. The dust generated by sandblasting is driven by the fan as the main power. It is sucked into the suction port of the sandblasting chamber by the suction of the fan, passes through the suction pipe, enters the dust collecting box, and is then blocked by the small aperture channel of the dust removal bag. Slowly accumulate on the wall of the cloth bag until it falls into the dust hopper at the bottom after the machine is stopped. After a certain period of time, by pressing the manual dust removal valve and vibrating the screen cloth bag, all the dust that cannot be automatically dropped falls into the dust hopper, and the clean gas is discharged out of the workshop, so as to achieve the effect of sand and dust separation and abrasive recycling.

1.3. Features:

1. The machine adopts negative pressure sand blasting, and the impact point is deep and the effect is ideal;

2. The blasting efficiency is fast, with instant control system;

3. Dust and sand separation, saving abrasives, good environmental protection effect.

Zinc alloy sandblasting, aluminum alloy sandblasting, metal sandblasting

1.4. Structure

The drum-type automatic sandblasting machine is mainly composed of a sandblasting host, a drum system, an abrasive recovery system, a ventilation and dust removal system, an abrasive sorting system and an electrical control system.

1.5. Sandblasting host:

The overall dimensions of the sandblasting host are 1450 (length) * 1000 (width) * 1800 (height). The sandblasting cabin is a fully sealed structure, dust-free and environmentally friendly sandblasting.

1.6 Main technical parameters of sandblasting host:

(1) Sheet material: δ=2mm cold rolled steel sheet

(2) Processing form: welding

(3) Dimensions of the equipment: 1450×1000×2250 (mm).

Two: main technical parameters

1. Clean up the product

(1) Width less than 50mm

(2) Height less than 50mm

(3) Length less than 50mm

2. Rolling basket system

(1) Working speed 0.3-9 rpm (speed regulating motor)

(2) Power Rate 400w×1 unit

(3) Speed ratio 1:150

3. Spray gun

(1) Type No. Type B Threaded Sandblasting Gun (2) Abrasive Shot Speed 65-70m/s

(3) Nozzle diameter φ8mm*35 (4) Pressure 3-8barr

(5) Number of spray guns 2

4. Dust removal system (1 set)

(1) Dust collector

a. Model 4050-6 b. Processing air volume 504m3/h

c. cloth bag φ100*600

(2) Centrifugal fan

a. Processing air volume 1800m3/h

b. Power 0.55kw

6. The power of the whole machine is 1.0kw

7. The total ventilation volume is 1800m3/h

8. Dimensions of the host

(1) Maximum external dimension 1000mm×1450mm×1800mm

Rolling Basket Sandblasting Machine

Three: Structural principle and adjustment use

This machine is a high-performance sand blasting cleaning equipment of rolling basket type. During the cleaning process, the rolling basket is driven by the motor to rotate, so that the product rolls in the rolling basket. The product is sprayed from two spray guns in all directions, and the oxide scale and dirt on it fall off quickly, and the surface of the workpiece obtains a bright surface with a certain roughness.

During the cleaning process, the sand falls into the sand bucket for collection and recycling. The dust is sucked into the dust box by the dust removal fan, and the dust collector is dedusted, and the efficiency can reach 99%, and the purified air is discharged into the air.

This equipment consists of the following functional parts: sand blasting host, rolling basket system, dust removal system, and electrical control system.

1. Sandblasting host

(1) Structural principle

The main machine consists of a cleaning room, a sand collecting bucket and two parts.

A. A total of 2 spray guns are installed in the cleaning room, which can achieve the best cleaning of the workpiece after the space structure CAD test and actual verification.

B. The cleaning room is a fully sealed room, and there is a certain negative pressure in the room to prevent dust from escaping.

C. Rubber is installed in the cleaning chamber to protect the walls of the chamber from wear and prolong the service life of the chamber; a network is installed on the cleaning cone to block debris, protect the nozzle, and facilitate maintenance by maintenance personnel.

(2) Adjust the use and maintenance safety

A. Cleaning the indoor guard plate and cast nut are wearing parts, which must be checked frequently for wear and replaced in time. When installing the guard plate, pay attention to lap joints to prevent damage to the wall panel and endanger safety.

B. Cleaning the indoor rubber curtain is a vulnerable part, if it is damaged, it should be replaced in time.

D. When overhauling, the power supply must be cut off, the warning must be listed, and live operation is strictly prohibited. Violators may endanger the safety of life.

2. Rolling basket system

(1) Structural principle

The workpiece rolling basket system of this machine is composed of an octagonal rolling basket and a speed regulating motor. The system has a smooth transmission and the running speed can be controlled by the speed governor.

(2) Adjustment and use

When using, according to the cleaning effect of the workpiece, adjust the speed of the rolling basket from slow speed to high speed, so as to achieve high-quality cleaning effect and good economic performance.

3. Dust removal system

(1) Structural principle

The bag filter is made of high-efficiency dust filter cotton cloth, centrifugal fan, dust collector, body, air duct, etc.

A. The body is welded by 2.0mm high-quality low-carbon steel plate, and the inner and outer surfaces are painted. Dimensions: 1000 wide × 1450 deep (with dust box) × 1800 high (mm).

B. High-efficiency dust removal bag φ110×600, a total of 4 pieces. The high-efficiency dust removal bag is used for dust removal treatment, and the purification effect meets the national environmental protection standards.

C. A-type transmission of centrifugal fan, power: 0.55KW, speed: 2800 rpm.

D. Cleaning method: the cylinder is vibrated to clean the dust.

Dual Gun Sandblasting Machine

Four: electrical system

(1) General technical requirements

1 Overview

The main circuit of the electrical equipment adopts 220 volts, and the control circuit adopts 220 volts. For the convenience of operation and maintenance, the electrical equipment is centrally installed in the control box, which controls the start and stop of each motor and solenoid valve.

2. Control object

(1) Dust removal fan 0.55kw

(2) Rolling Basket Motor 120w

(4) Lighting lamp

(5) Solenoid valve ; 1

(2), electrical operation instructions

1. Turn on the main power switch, turn on the power, and the power signal light is on;

2. Adjust the air pressure of the spray gun, turn on the rolling basket and sandblasting in turn.

After the workpiece is processed, close the sandblasting and rolling baskets in turn.

Please follow the instructions of the installer of our company for specific operations. This instruction only briefly introduces the operation sequence for reference only.

Switching on and off and blasting procedures

1. According to the size and weight of the workpiece to be processed, adjust the angle of the spray gun, the distance from the workpiece and its movement stroke to a suitable position, especially for the USB interface type, small and light workpieces, it is necessary to reduce the pressure for sandblasting, and adjust the sandblasting at the same time. The spray angle is opposite to the rotation direction of the drum, and it hits the bottom of the drum to the position where the workpiece rolls and falls, and changes the trajectory of the workpiece rotation driven by the airflow, so as to prevent the workpiece from being carried out of the drum by the airflow, resulting in the workpiece being unable to be uniform with sandblasting;

2. Turn on the compressed air, based on the data displayed on the air pressure gauge. When there is no work, the pressure gauge shows 8 workpiece pressure, and when it is working, it is 4-6 kg pressure. For light workpieces, reduce the pressure to 3-4 kg. Air pressure to avoid blowing the workpiece, and a baffle or anti-flying cover can also be added to the gun bracket to cover the drum;

3. Start the power supply (lighting system);

4. Start the dust removal system the dust removal fan works normally

5. Close the cabin door and check whether other orientation doors are closed;

6. Turn on the switch of the number of sandblasting guns to be turned on, press the sandblasting start switch, the sandblasting gun will automatically drop to the appropriate position of the drum, and then the sandblasting gun that has turned on the switch starts sandblasting;

The factory preset sandblasting time of this machine is 10 minutes, that is, the machine will automatically stop after 10 minutes of sandblasting. At this time, after the dust in the sandblasting chamber is removed (usually 5-10 seconds), open the hatch. , observe the sandblasting effect of the workpiece, if it is not ideal, close the hatch and repeat the above steps for sandblasting. After mastering the correct ratio and time between the weight of the sandblasted workpiece and the sandblasting time, you can directly set the sandblasting time, carry out complete sandblasting, take out the drum after shutdown, and dump the workpiece into the turnover box.

7. After the normal sandblasting reaches the predetermined time, the sandblasting gun will automatically stop sandblasting, rise to the preset position, and the dust removal fan will continue to operate until manual intervention is turned off;

8. The processing is carried out in sequence according to the sandblasting process;

9. Turn off each switch according to the above reverse process when getting off work;

10. Regularly add sand and clean the dust on the bag and the dust hopper of the dust removal box. Whether to add sand depends on the processing effect of the sandblasted workpiece. You can also add new sand regularly and quantitatively according to the sandblasting time after you are familiar with the operation to ensure the sandblasting effect. consistent;

Application of relevant national standards for sandblasting engineering

1. GB7963-87 "Safety Regulations for Painting Operation, Ventilation and Purification of Pre-painting Process"

2. GB7691-2003 "Coating Operation Safety Regulations" General System of Safety Management

3. GB16297-1996 "Comprehensive Emission Standard of Air Pollutants"

4. GB7692-87 "Safety Regulations for Painting Operation Safety Pre-painting Process Safety"

5. JB/T8355-96 "General technical conditions for sandblasting equipment"

Dongguan Meijun Automation Equipment Co., Ltd.

Engineering Design