Products Center

Tel:+86-769-82261696

Meijun Automation Equipment Co., Ltd. is an all-round company integrating sandblasting machine, sandblasting machine accessories and sandblasting room. We can customize sandblasting equipment suitable for customers according to customer needs, with good quality, low price and safety. The high number is mainly

Environmentally friendly, dust-free and zero-emission.

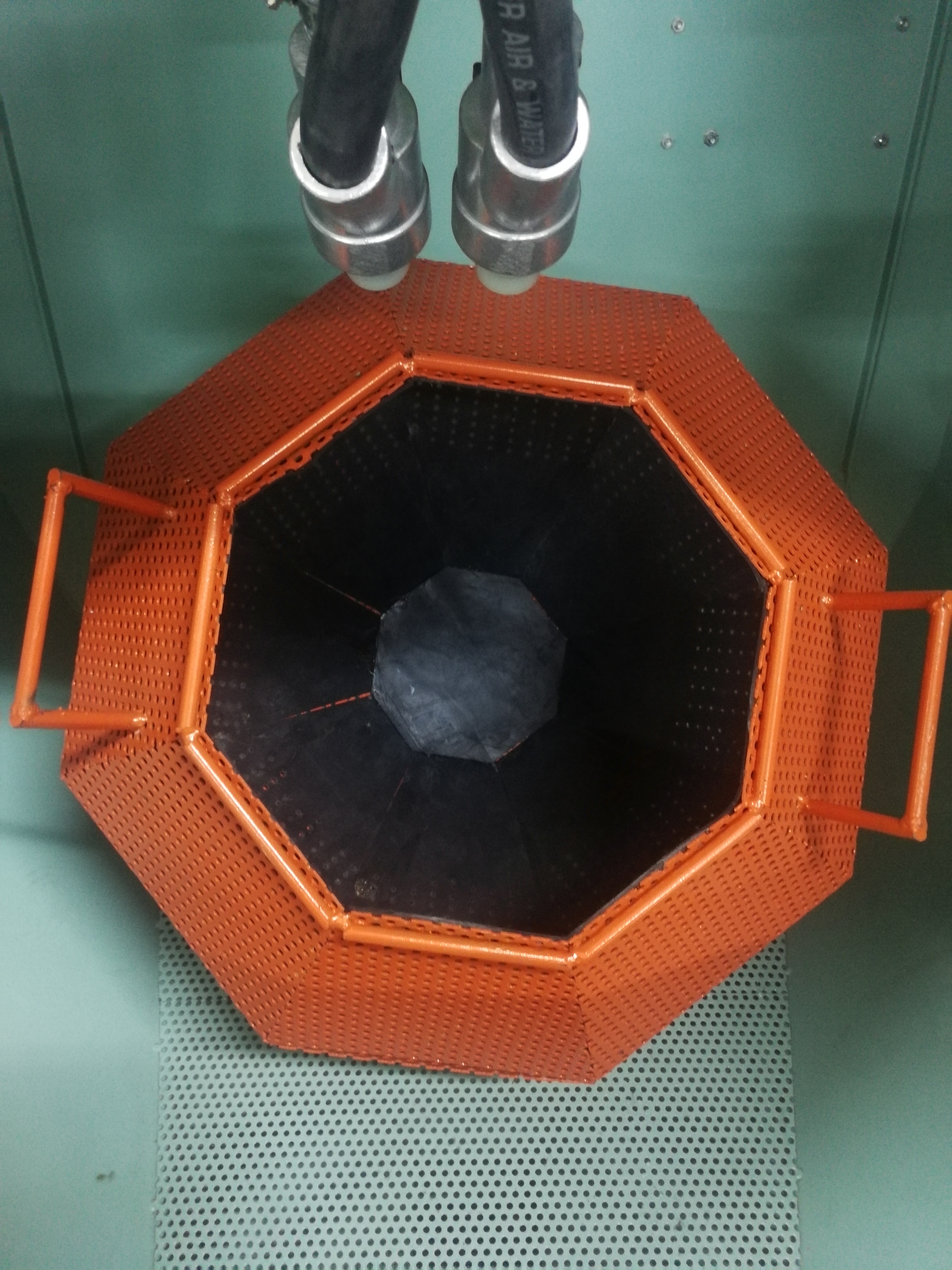

Meijun Double Gun Roller (Rolling Blue) Type Hardware Automatic Sandblasting Machine Features:

1.The sand blasting speed of this model is more than 2 times that of the general manual sand blasting machine;

2.Automatic control, automatic sandblasting;

3.The rotation speed of Meijun drum (rotating basket) adopts frequency conversion speed regulation, which runs smoothly and can meet different processing needs; the spray gun adopts swing mechanism,

4. with timing, jogging, positioningSandblastingetc.;

5. Easy loading and unloading of workpieces, simple operation, saving human resources;

6. The size of the roller and the number of spray guns can be set according to customer requirements;

7.Suitable for mass production of small workpieces, such as zipper heads, screws, etc.

General sandblasting workpiece range: used for batch processing of small hardware (plugs, USB interfaces, screws, small rollers), gears, saw blades, and round shafts.

Its roller and roller are automatically rotated, easy to load and unload, and efficient. The spray gun can be manual or automatic, and it is also suitable for plastic products such as skeleton switches IC electronic plug-ins.

Equipment size and shape can be customized according to user needs.

8.The sandblasting time can be set as required, with automatic sandblasting at regular intervals and jog positioning function; it can be customized according to customer requirements; it is suitable for small hardware and plastic parts Batch processing, high sandblasting efficiency, and the blasting operation can be manual or automatic.

Equipment dimensions: L1000mm*W800mm*1950mm (length*width*high)

Internal dimensions of equipment compartment: 900mm*800mm*780mm (length*width*high)

Roller size: 500mm (diameter) (20-30kg) can be equipped according to customer's workpiece size Roll Blue

Gun Specifications: (20*8*60mm)2 wear-resistant sandblasting guns

Roller speed: 8 to /min

(can be installed with frequency conversion speed regulation)

Roller Motor: 380V/50HZ/400W

Dedusting motor: 380V/50HZ/550W

Air supply requirements: pressure 2-7bar(kg/cm2)

Compressed flow: 1.5-2.0m3/min

Steel thickness: 2- 5mm

Goggle Frame: 1

Operation opening: 2

Blast Gloves: 1pair

Single processing: 1-20KG

Machine Light: 220V

13WLEDExplosion-proof Energy Saving Lamp

Separator air volume: 12m3/min

Total weight of equipment: 300KG

Total volume of equipment: 3m3

Total equipment power: 380V/50HZ/1100W

Dust removal method: bag type dust box ( can be equipped with secondary filter zero emission dust removal)

Scope of application

Electronic Hardware,ABSPlastic,Acrylic, Resin and other workpieces or handicraft sandblasting. Five-gun automatic rotary liquid sandblasting machine, suitable for small batch production of large and medium-sized parts.

Above models:

1, air source requirements: pressure7barflow0.4-1.0 m³/min

2, can be customized according to customer's required size

Instructions

1, preparatory work: prepare a suitable size nozzle, enough air flow and rated pressure air compressor, uniform and dry abrasive, safe and comfortable protective mask (protective clothing and helmet).

2, connect the air source, blasting pipe, nozzle, and make sure that all connections are correct and firm.

3, open the air inlet valve until the air pressure in the cylinder reaches 0.7MPa; check whether the connections are leaking gas.

4, put an appropriate amount of abrasive in the cylinder, do not fill it too much (2/3).

5, hold the front end of the sandblasting pipe firmly, open the sand valve, and make the nozzle at a proper angle and distance point to the surface of the object to be cleaned.

6. When the abrasive needs to be added after the abrasive is sprayed in the sand tank, or when the sand blasting needs to be stopped due to a fault, first close the air intake source, and then open the exhaust ball valve to discharge When the gas is exhausted, the abrasive can be added or the processing of maintenance and other matters can be carried out.

Workpiece surface cleaning

Scale, residual salt, residual oil, etc. after heat treatment; oxidation of black(with)color castings Skin, molding sand, etc.; oxide skin, molding sand, etc. of precision castings without allowance; residues, microburrs, etc. of machined parts; oxide skin, welding slag, etc. of welded parts; cold and hot-rolled steel plates(section steel) oxide scale, rust layer, etc.; mold release agents, deposits, etc. of various mold cavities; ceramic components surface Sintering residues; flashing of plastic moldings; radioactive elements on the surface of objects; bridges, hydroelectric power station gates, ships, buildings; rubber adhesion layers of airport runways; railway carriages; various pipes and containers; oil pollution of old machinery parts , attachments, etc.; residual paint, rust layer and attachments of containers, etc.; wrong sintered layer on porcelain; scratches on decorative surfaces....

Pretreatment of workpiece surface before coating

Before painting and baking; Before plastic spraying; Before metal spraying; Before galvanizing, chrome, nickel; Before oxidation treatment; Before flaw detection...

1. Change the physical and mechanical properties of the workpiece to improve or reduce the surface roughness; change the surface tensile stress to compressive stress; improve the lubricating state of the surface; reduce the motion noise of the couple; improve the friction coefficient of the surface...

2. Finishing of workpiece surface

Polishing of metal exterior decorative surfaces; obtaining matt or diffusely reflective surfaces; polishing of woodwork surfaces…

3. Parchment and other artwork cleaning and preservation

4. Clean surfaces such as brushes, contacts and wiring to improve conductivity.

Sandblasting machine we (Meijun Automation Equipment Co., Ltd.) are professional.

The company's mechanical products provide a one-year warranty service.