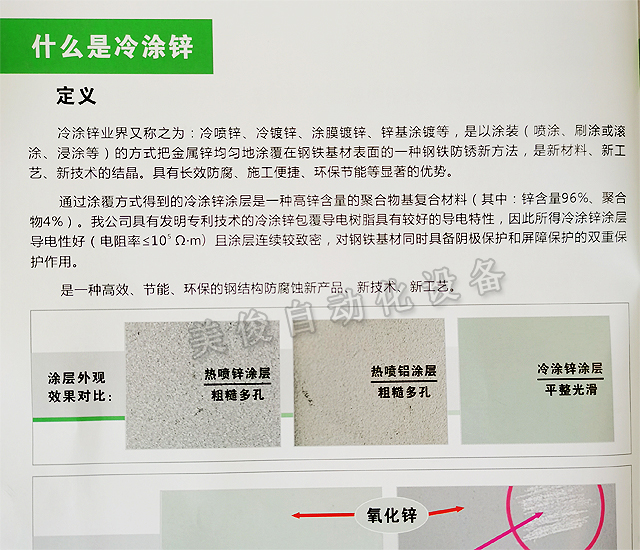

1. Cold spray zinc

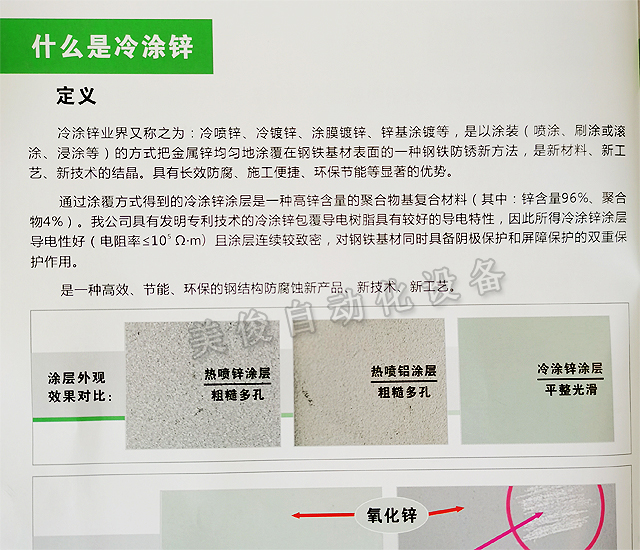

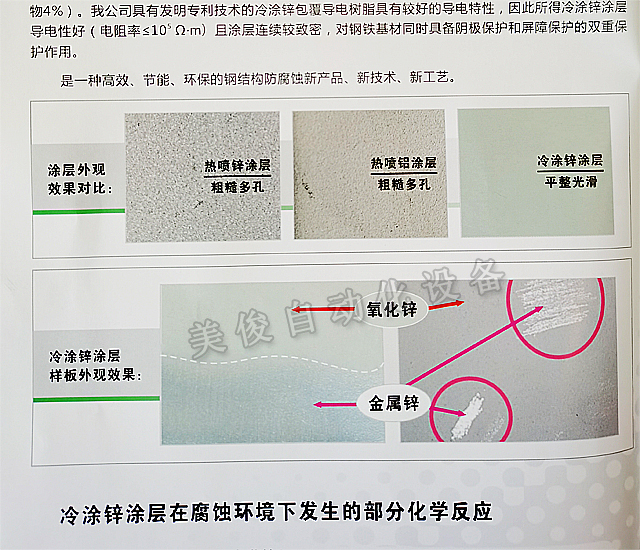

Cold spray zinc is also known as Cold galvanized and cold coated zinc are one-component zinc-rich coatings with high zinc content. Cold spray zinc is a galvanized coating prepared from three parts of zinc powder with a purity higher than 99.9%, volatile solvents and organic resins. Compared with other two-component zinc-rich coatings or other one-component products, the zinc content of cold spray zinc coatings is extremely high (more than 96% zinc in the dry film), resulting in excellent corrosion resistance of cold spray zinc coatings to steel. Compared with the traditional galvanizing process, cold spray zinc has the advantages of environmental protection, high solid content, and low VOC organic volatiles. With the background of the rapid development of the industry, environmental protection must be the trend of future development. Cold spray zinc It will also gradually replace the traditional galvanizing process. Cold spray zinc is widely used in various steel components and facilities, such as marine atmosphere, industrial atmosphere, urban atmosphere, old and new steel structure anticorrosion, such as equipment manufacturing, infrastructure, transportation facilities, wind power, metal smelting, theme parks and other steel structures. Effective anti-corrosion, such as power transmission and transformation systems, power generation systems, bridges, building steel structures, concrete mixing station steel structures, towers, tunnel facilities, containers, ships, port facilities, water conservancy gates and their ancillary steel structures, reinforced steel bars, car bodies , pipes, troughs, silos, signs, fences, heating facilities, roof steel structures, etc.

Second, cold spray zinc products Features

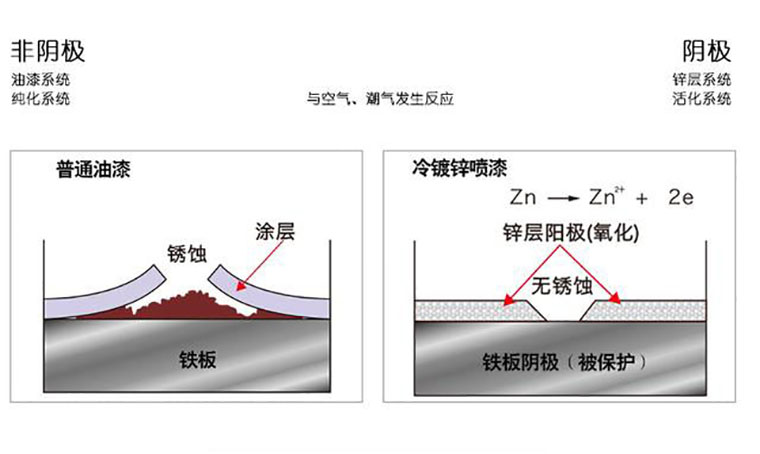

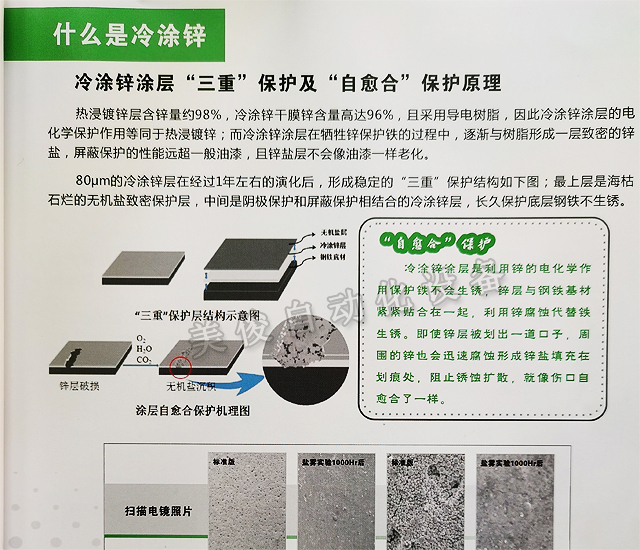

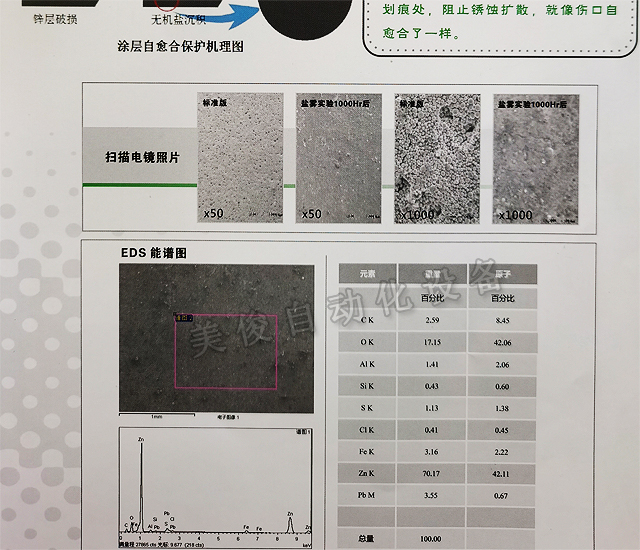

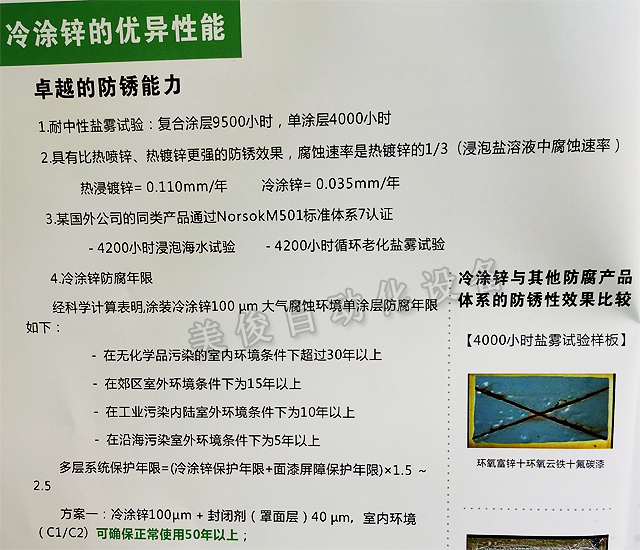

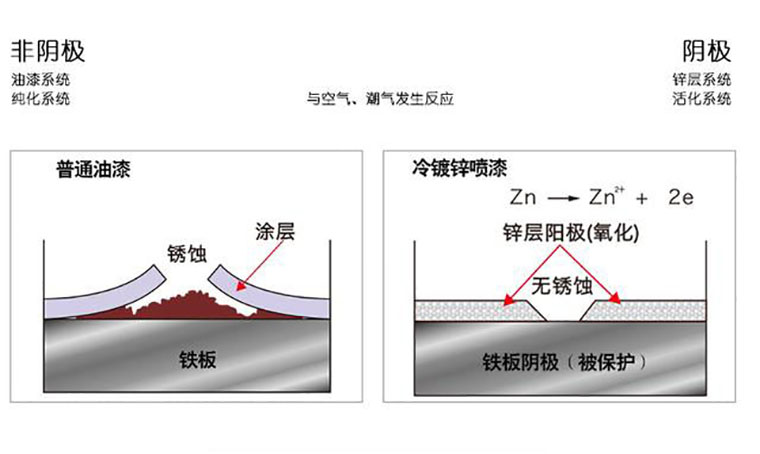

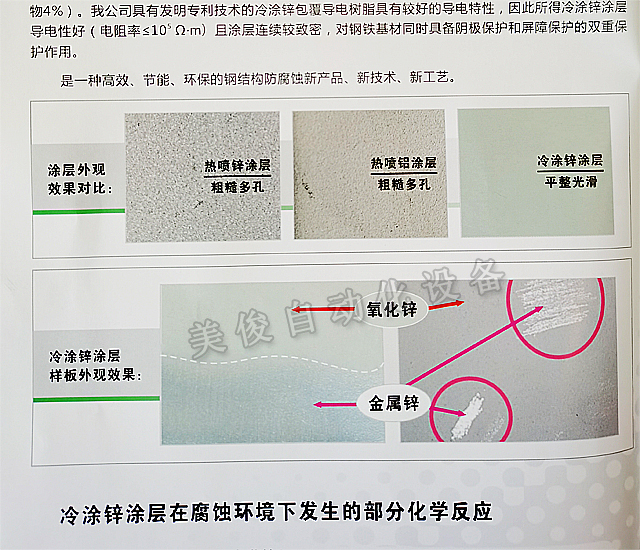

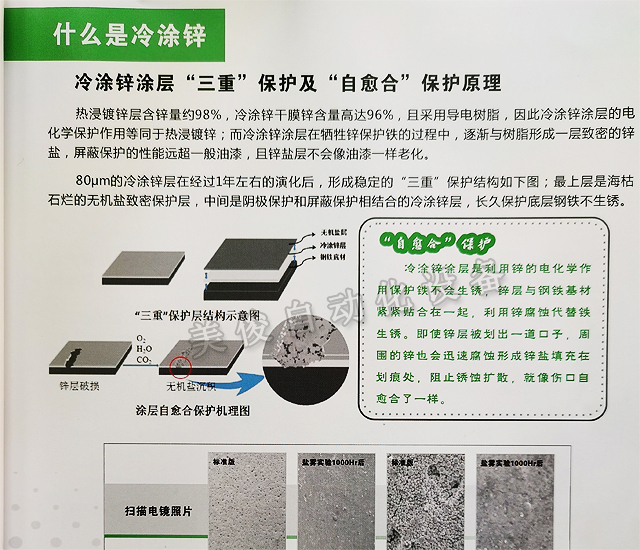

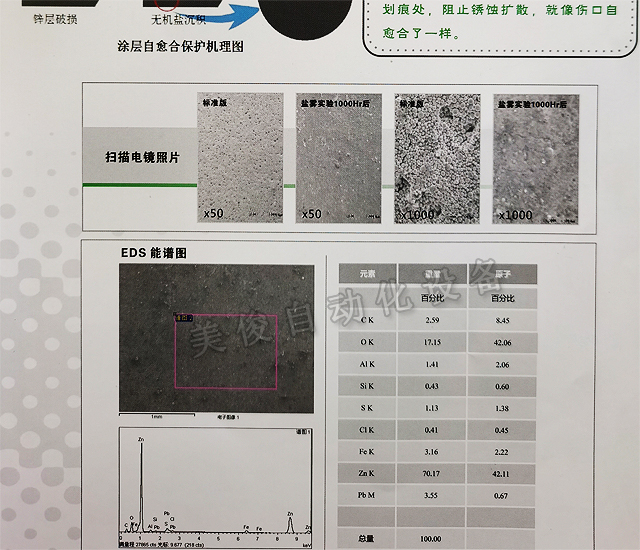

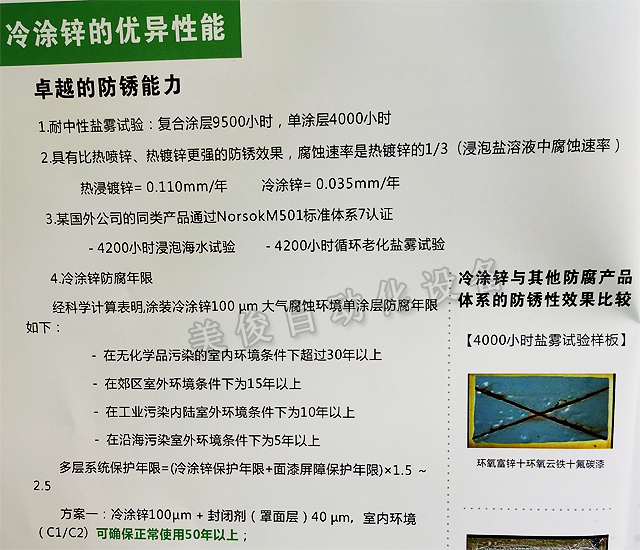

1. Excellent anti-rust effect of cold spray zinc ---Cold spray zinc has dual functions of cathodic protection and barrier protection

2. Cold spray zinc is easy to operate and easy to use-----one-component zinc-rich coating This product is a one-component zinc-rich coating, compared with two-component and three-component coatings, there is no use The previous tedious mixing process and the limitation of paint usage time. Cold spray zinc is easy to operate, no special technology is required, just stirring evenly to ensure the necessary coating thickness.

3. Cold spray zinc excellent primer, good When the cold spray zinc coating is used as the primer in the anti-corrosion coating system, it has a good compatibility with a variety of coatings (except alkyd oil-based coatings).

4. Fading----The color of the paint film is Gradually change in the sun. Cold spray zinc can be used as a set of anti-corrosion system alone, and with the oxidation of zinc powder in the atmosphere, the color of the coating will gradually change. Cold spray zinc has the same degree of fading ability as galvanized sheet.

5. Conductive cold spray zinc has the effect of conducting static electricity , however, does not have the same conductivity as conductive paint.

cold spray zinc construction process

cold Zinc spraying surface treatment The steel surface must be sandblasted or shot blasted to remove surface impurities, rust, oil, dust, etc., increase the roughness of the steel surface, and improve the adhesion of cold galvanized paint, which is very important for surface treatment. The requirements are higher, and the Sa2.5 standard must be met to ensure a good adhesion effect.

Paint construction Before construction, special Thinner, the addition amount is 30%-50%, depending on the specific situation. The solid content of cold spray zinc paint is high, and it needs to be fully stirred to uniformly disperse the zinc powder and avoid precipitation during the spraying process. Cold spray zinc paint can be sprayed with air or airless (recommended). The thickness of one spray should be less than 150 microns to avoid paint sagging. Zinc rust may appear on the surface of the paint film after the cold spray zinc paint has dried. It needs to be polished off before applying the next paint, otherwise the adhesion between layers will be affected.

Topcoat Cold spray zinc finish Relatively rough, it is recommended to use a special cold spray zinc paint sealer to prevent the paint film from blistering. Matching epoxy micaceous iron intermediate paint, topcoat can be acrylic polyurethane topcoat or fluorocarbon topcoat.