Products Center

Tel:+86-769-82261696

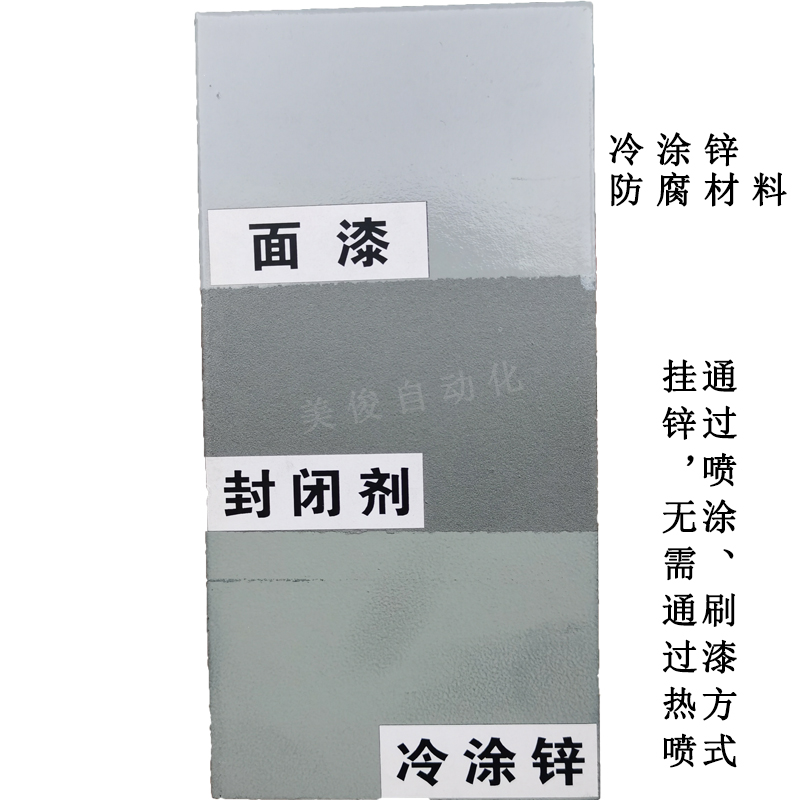

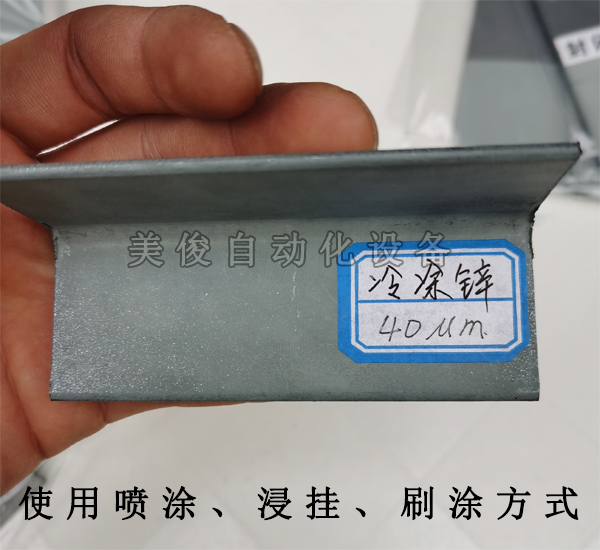

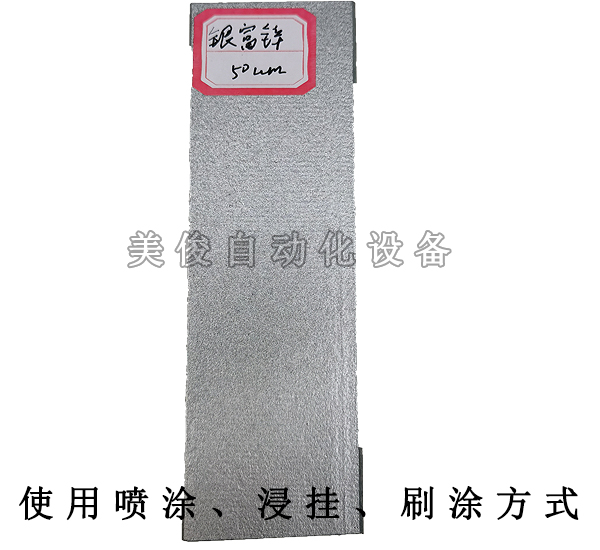

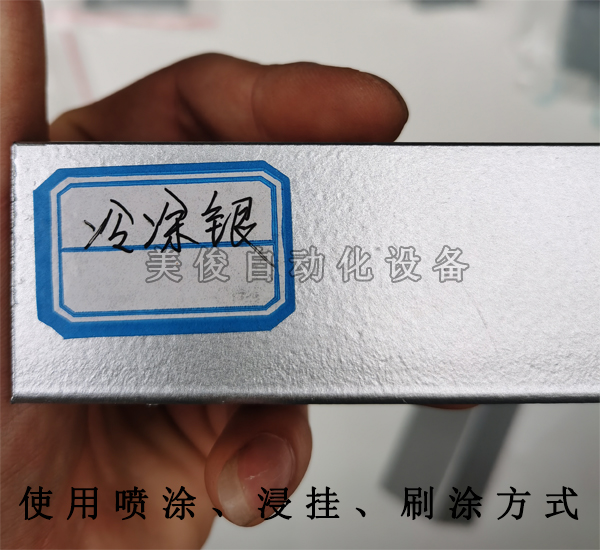

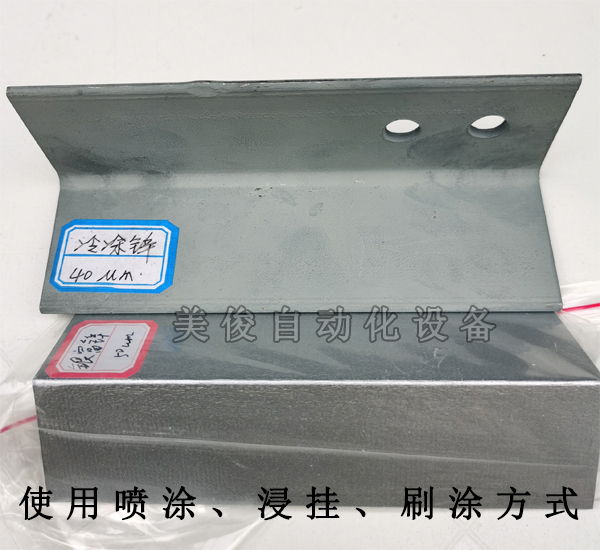

What is cold zinc coating? Cold-coated zinc is an environmentally friendly anti-corrosion coating material. It is coated by airless spraying, dipping, brushing, etc. It is equivalent to paint, but it does not have the irritating volatile gas of paint and no carcinogens. Cold-applied zinc is based on: "triple" protection and "self-healing" protection principles.

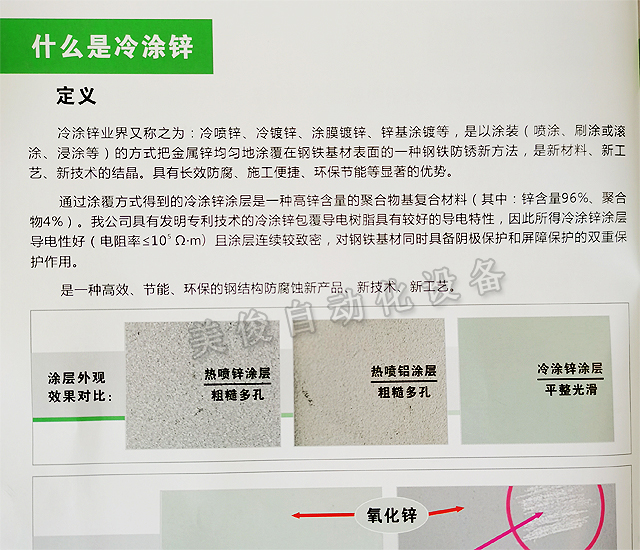

Cold zinc coating industry is also known as; cold spray zinc, cold galvanizing, coating galvanizing, zinc-based coating, etc. A new method of steel rust prevention, which is a new method of uniformly coating metal zinc on the surface of steel substrates by coating (spraying, brushing or rolling, dipping, etc.), is the crystallization of new materials, new processes and new technologies. It has long-term anticorrosion and convenient construction. Significant advantages such as environmental protection and energy saving.

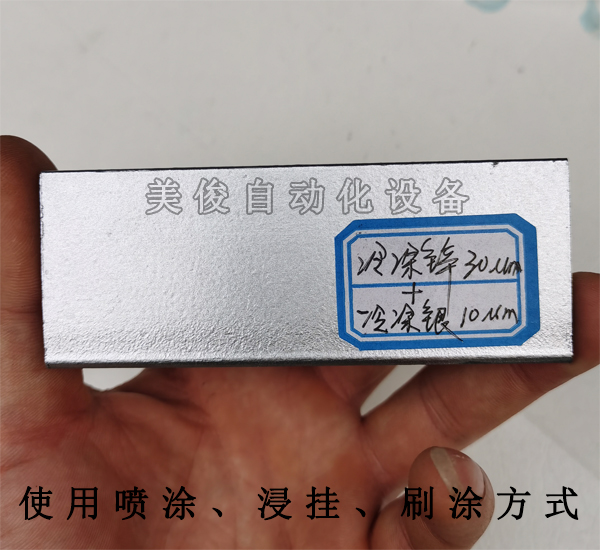

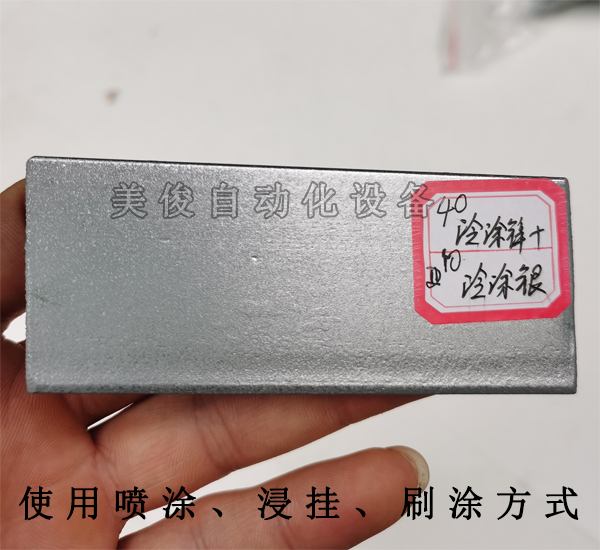

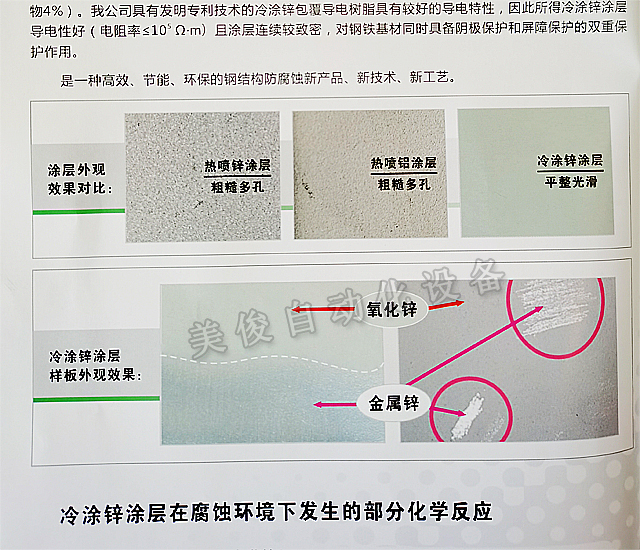

The cold-applied zinc coating obtained by coating is a polymer matrix composite material with high zinc content (wherein: zinc content 96%, polymer 4%). The cold-coated zinc-coated conductive resin with the patented technology of our company has good electrical conductivity, so the obtained cold-coated zinc coating has good conductivity (resistivity < 10 ohms) and the coating is continuous and dense, which is suitable for steel substrates. At the same time, it has the dual protection function of cathodic protection and barrier protection.

Cold-applied zinc coatings are highly efficient. New energy-saving and environmentally friendly steel structure anti-corrosion products, new processes and new technologies.

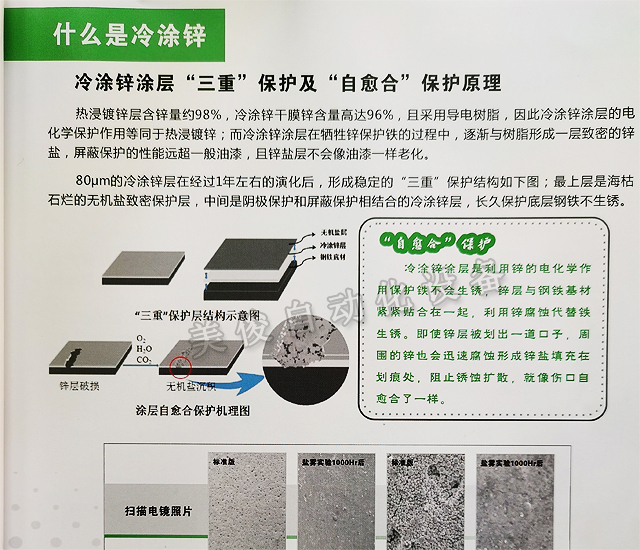

Cold-coated zinc triple protection and self-healing principle:

The zinc content of the hot-dip galvanized layer is about 98%, and the cold-coated zinc dry film The zinc content is as high as 96%, and the conductive resin is used, so the electrochemical protection effect of the cold-applied zinc coating is equivalent to that of hot-dip galvanizing; while the cold-applied zinc coating gradually forms a layer with the resin in the process of sacrificing zinc to protect the iron Dense zinc salt, the performance of shielding and protection far exceeds that of ordinary paint, and the zinc salt layer will not age like paint. After about 1 year of evolution, the 80um cold-coated zinc layer forms a stable ''triple' protection structure. The top layer is a dense protective layer of inorganic salts, and the middle is a cold-coated zinc layer that combines cathodic protection and shielding protection. , to protect the underlying steel from rusting for a long time.