Products Center

Tel:+86-769-82261696

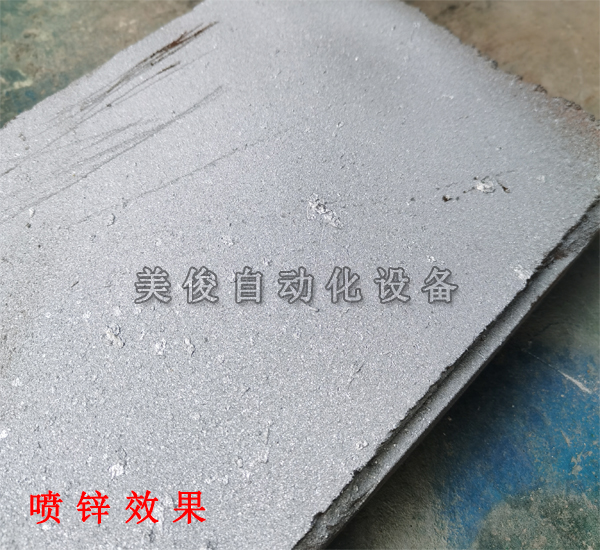

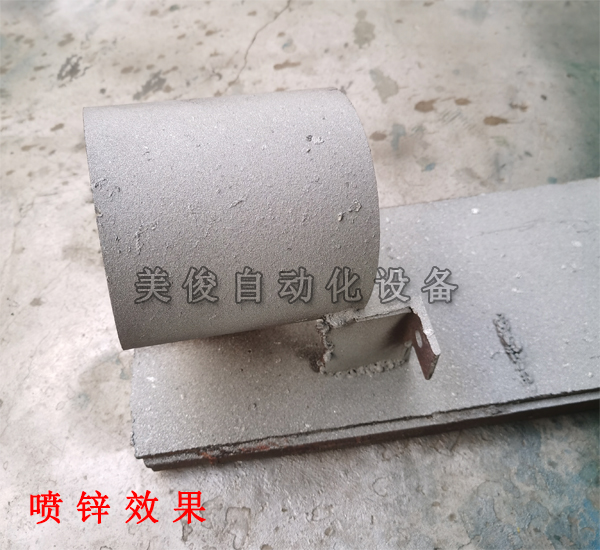

Every time the three-phase 380V power supply is turned on, the control system will identify the position of the spraying switch. Alarm prompts to ensure safe power transmission. Introduction: The zinc spraying machine/aluminum spraying machine adopts the flat characteristic technology. The main power supply of the traditional zinc spraying machine/aluminum spraying machine uses the DC main machine. During the spraying process, the carbon burning loss is large, which reduces the hardness of the coating. The power supply of this zinc spraying machine/aluminum spraying machine can be sprayed at a lower voltage after the flat ampere characteristic is adopted, so that the burning loss of carbon in the coating is greatly reduced. Reduced (about 50%), can maintain a good arc length self-adjustment effect, can effectively control the arc voltage, when the spraying power supply changes the wire feeding speed, the spraying current changes rapidly, and maintains a stable arc spraying process.

(Reminder: If the steel structure needs anti-corrosion surface treatment, it needs to be used with a sandblasting machine. Sandblasting and rust removal to clean the oxide layer on the surface of the steel structure to increase the roughness is conducive to improving the adhesion of zinc spraying)