Products Center

Tel:+86-769-82261696

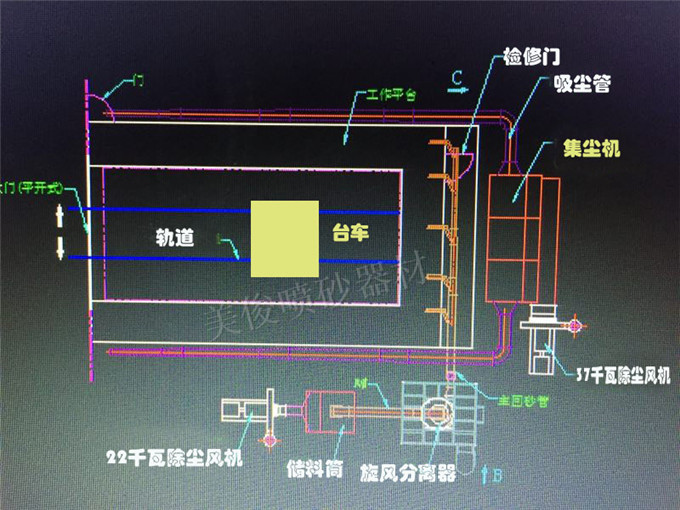

Dongguan Meijun Sandblasting Equipment Environmentally friendly wind power sand blasting room, large wind suction device, smooth sand return and sand extraction and low failure

The working principle of honeycomb dust and sand separation sandblasting room:

The sandblasting room is mainly divided into sandblasting system, sand recovery, separation, dust removal system, and house dust removal system.

Precautions:

Adopt honeycomb floor to automatically return sand;

1) The sandblasting machine is required to be linked with the lower sand bucket, and the sandblasting machine needs to have the ability to automatically control sand addition, such as linkage system, material level sensor sensing system, etc.; (different machine models, the requirements of the sandblasting machine for manual sand collection are different increase, the cost has changed)

2) Increase the abrasive lifting system;

3) Increase the abrasive dust separation, screening and storage system.

1: Sand collector bucket at the bottom of the sandblasting room

The bottom sand collecting hopper adopts the modular splicing mode. The whole collecting hopper of each unit is welded by steel plate and channel steel, and then spliced according to the required area (screw fixed, detachable). The sand in the unit is conveyed by a screw, and the abrasive is collected to the side sand collecting. Then the mechanical bucket is used to lift it to the cyclone sand separator at the bottom of the sandblasting tank to separate the sand and dust, and then the abrasive falls into the sand collecting hopper, and the sand is automatically added according to the sandblasting start and stop status. Dust and small unusable abrasive waste The particles enter the dust collector through the suction pipe, and fall freely in the dust hopper at the bottom of the dust collector.

Tip: According to the customer's simple and cost-saving model, the customer will excavate a square trench pool, an integral steel plate sand bucket, two sets of screw conveyors are placed vertically and horizontally at the bottom, and a 5*8 meter honeycomb grid floor is placed on the top.

2Set of screw conveyors(transverse and longitudinal) +2 Motor+ All steel plate sand bucket

Two: grille floor

The floor of the sandblasting room adopts metal grating, which is conducive to the collection and discharge of steel sand on the one hand, and the other

The surface is conducive to the safety of workers walking. In order to prevent large impurities and foreign objects from entering the sand return pipe through the honeycomb during working hours and blocking the spray gun, the equipment is equipped with a filter screen at the lower part of the grille (honeycomb floor) to prevent impurities and foreign objects from entering. It is very convenient to clean up impurities and foreign objects. It is only necessary to open the grille laid on the ground inside the house to clean it thoroughly, so as to ensure that the recycling pipe network can work smoothly for a long time.

The floor grid is welded by 40*4mm flat steel bars or prefabricated grid floor. specific

The size and quantity of the trolleys are determined by the size of the house and the rail spacing of the work trolley. Generally, the floor grille inside the sandblasting room has a load-bearing capacity of less than 200kg per square meter. If a larger floor grille load-bearing requirement is required, the customer needs to put forward special design requirements.

5*8meter grid floor+channel beam frame(Hours & Time,Manpower)

Three: sand recycling system

1) Sand collection bucket

The bottom of the sandblasting room is the area for collecting sand and arranging dust suction pipes, which is specially used to collect sand blasting.

Scattered abrasive and dust from blasting. In this scheme, the sand collecting area is made of steel plate into a sealed inverted "V" shape, which is conducive to the recovery and capture of abrasives and dust. The sand hopper module combination of the sandblasting room can be disassembled.

The honeycomb sand return system fully considers the wear and maintenance of the honeycomb recycling floor and recycling pipeline during long-term use, and makes the recycling floor and recycling pipeline a detachable modular combination, which makes the maintenance work of the equipment extremely simple and fast, saving money. A large number of parts are replaced to reduce the maintenance cost of the equipment during long-term use. The sandblasting room of this type of structure only needs to make the depth of the trench to 1 meter (the depth of the trench is selected according to the number of integrated buckets used, the smaller the number, the higher the excavation depth).

The bottom of the honeycomb floor is evenly covered with honeycomb small buckets. These small buckets are connected to the sub-pipeline conveying trough under the small bucket. The inside of the pipeline is conveyed by reverse screw; When the sand is sprayed out, all the sprayed sand falls into the honeycomb-type small bucket, and then falls from the small bucket into the sub-pipe conveying tank, and finally falls into the horizontal main conveying tank in the middle of the sand collecting bucket at the bottom, and returns to the main conveying tank pipeline through the pipeline. The bottom of the elevator is lifted to the sand and dust separator through the bucket in the elevator, and after the sand and dust is separated, it falls into the storage hopper at the bottom of the separator, and waits for the sand-loading valve to open and falls into the sand blasting machine tank.

Honeycomb recycling floor has a relatively fast and simple maintenance method.

First of all, the honeycomb floor has a simple structure, few parts that are easy to wear, and less parts need to be maintained; and the honeycomb floor adopts a block combination method, which can easily disassemble each part and enter the maintenance point. Then the honeycomb floor makes the easily worn elbows and other components into "standard parts", that is, standard replacement parts, which are connected with flange interfaces. When replacing, just open the bucket plate, loosen the interface, take out the worn parts and replace them with new parts. , without on-site welding and cutting. Greatly facilitates daily maintenance.

2) Mechanical bucket elevator

Specification: Height 4200MM (determined according to the height of sand tank)

Upgrade body size: 600*220MM

Lifting motor: 1.1-2.2kW (depending on abrasive type and sand tank height)

Four: sand and dust separation system

In order to ensure the quality and efficiency of sandblasting, the mixture of sand and dust recovered from the honeycomb floor must be effectively separated.

After the sand and dust are separated, the sand can continue to be recycled. The main function of the sand and dust separator is to separate the sand and dust with high efficiency and high precision.

The quality of the separation effect directly affects the sandblasting performance of the sandblasting machine and the filtration performance of the dust collector.

What needs to be used here is the sand and dust separator:

1) Cyclone Dust Separator + Dust Collector (7.5HP)

This sand and dust separator adopts the Japanese series separator specially designed by our company for sand blasting system, and adopts air separation to separate abrasives of different particle sizes.

It can effectively separate the sand and dust in the recovery system, and the separated complete sand is returned to the main body of the sand blasting machine to continue to be recycled. Clean up regularly.

The function of the cyclone inertial separator is to make the dust-containing gas rotate, and use the centrifugal force to capture the fine particles of dust from the airflow. This air-selective separator has a simple structure, stable performance, no moving parts, and is easy to maintain and manage. It is a widely used primary dust removal equipment, and the dust removal efficiency is generally about 90%. The separator configured by this equipment adopts the latest structure and is precisely designed.

The lower end of the separation unit is provided with a sand collector (storage box), and the outer side of the unit is provided with a frame for maintenance and protection. The spiral body group on the separation unit is connected with the filter (filter element) dust collector, which is conducive to reducing noise and improving the quality of the working environment. By adjusting the adjustment mechanism on the sand dust separator, the diameter of the separated sand can be adjusted, which is suitable for brown steel jade. , steel shot, steel sand and other sand and dust separation occasions, the applicability is very strong.

During the working process of the sand and dust separator, the high-speed impact part of the sand material is a vulnerable part. Our company has fully considered this problem in the design process, and has made a reliable protection treatment for the interior of the pipeline.

The protective plate is made of high wear-resistant material. During use, the protective plate can be inspected regularly. When the protective plate is worn out, it should be replaced in time to avoid wearing through the wall of the sand separator and then repairing it. This can ensure that the original appearance of the equipment will not be damaged, which can save a lot of maintenance and repair time.

Separating abrasive types: steel grit/corundum.

2) Maintenance platform and sand storage bucket protection frame

There is a sand collector (sand storage bucket) at the lower end of the separation unit. The sand storage bucket needs frequent maintenance, observation and prevention of blockage. Therefore, there is a maintenance and protection frame on the outside of the unit. It is equipped with stairs, and personnel can climb up and down at will. There are fences on the platform to prevent people from accidentally falling.

Five: storage hopper system

The storage hopper is one of the important components of the house equipment.

All the sand goes through the sand separator

Short-term storage in the storage hopper after separation.

When the sand in the blasting machine is used up, the storage hopper automatically replenishes the sand in the blasting machine.

Six: Dust removal system 2 10HP dust collectors

The dust removal system consists of suction and dust discharge pipes, bottom and side dust suction ports, modular filter cartridge dust collectors, dust discharge fans, and dust discharge chimneys.

The working principle of the dust removal system:

Install  The sandblasting room with the honeycomb floor sand return system, the dust removal system in the sandblasting room can adopt the circulation vacuum treatment method of upper air intake, lower and side exhaust air (see the work of the house body schematic).

The sandblasting room with the honeycomb floor sand return system, the dust removal system in the sandblasting room can adopt the circulation vacuum treatment method of upper air intake, lower and side exhaust air (see the work of the house body schematic).

The clean air enters the sandblasting room from the top of the room, and the dust removal fan sucks the polluted gas in the room into the dust collector through each suction port for collection and treatment. Since the dust recovery suction ports of the environmentally friendly pneumatic recovery sandblasting room are all arranged under the honeycomb sand suction floor and on the side walls of the house, the airflow drives the dust to move from top to bottom, and the dust is always suppressed in the sandblasting. Therefore, the dust concentration in the space above 0.5 meters in the sandblasting room is very low, the visibility is very high, and the working environment is good.

The sand recovery fan is collecting sand and dust from the honeycomb floor into theWhen entering the sand separator for sand and dust air separation and separation treatment, a part of the useless dust is also sucked into the filter element for dust collection and treatment, and the clean air is discharged to the atmosphere. The dust discharge pipelines of the two dust exhaust fans can be combined as required, and finally enter the exhaust chimney to achieve the standard requirements of standard discharge.

Company address : No. 33, Xinxing Road, Xinlian Community, Humen Town, Dongguan City

Company Tel: 0769-82261696 Mobile: 13215392671 (WeChat )

Company website: http://www.dgmagin.com