Products Center

Tel:+86-769-82261696

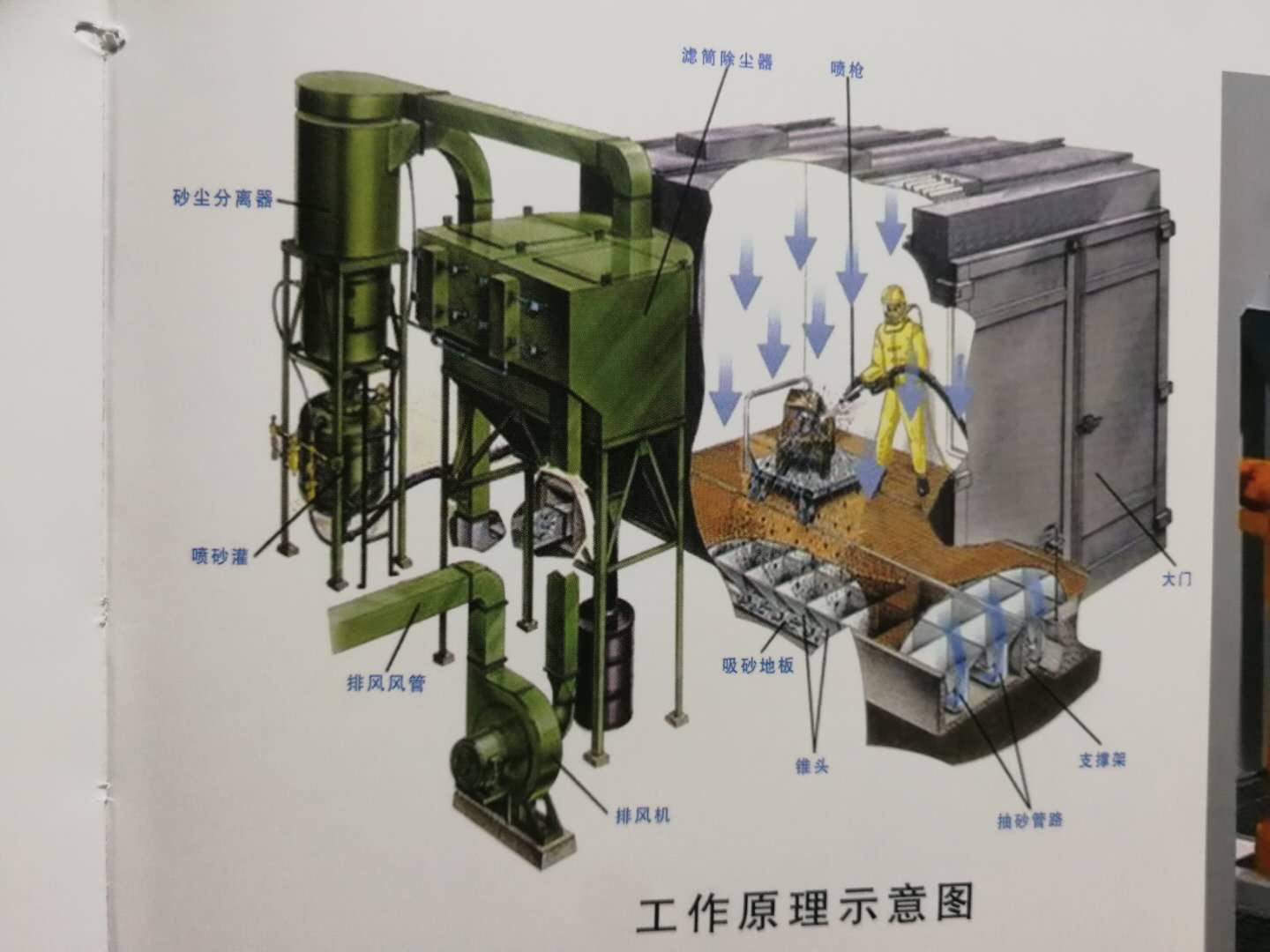

Main components and functions of sandblasting room equipment

The equipment is mainly composed of: sandblasting room system, sandblasting system and protective equipment, sand material recovery system, sand and dust separation system, storage hopper system, dust removal system, environmental protection noise reduction system, workpiece conveying trolley system, electrical control system, etc. part composition.

1. Sandblasting room system

The sandblasting chamber consists of a lightweight sandwich steel color plate structure chamber body, a working door, a safety door, an observation window, a wall protection layer, a filter air inlet, a ground grille, and a lighting system. It is an all-weather sandblasting and rust removal treatment. ideal place.

1.1. Sandblasting room with light steel color plate structure

The house body is made of profiles as the basic frame, partially reinforced, and the outside is made of 50mm thick color steel sandwich panels, which are beautiful in appearance, convenient in installation, anti-corrosion and durable.

The sandwich layer of the color steel plate is polystyrene foamed plastic. Compared with the conventional sandblasting room made of pure steel plate, it has the following characteristics:

(a) The house has good corrosion resistance, weather resistance and waterproof performance, and can be placed in the open air: if the sandblasting house is placed outdoors, it is only necessary to build a simple rainproof shed, and no need to build another factory building, which greatly reduces the infrastructure construction. cost;

(b) Good sound insulation and thermal insulation function:

The sandblasting chamber body is made of sandwich color steel plate, and the sandwich material is polyethylene foam plastic.

Has good thermal insulation function. It can convert the 1500HZ-2000HZ generated during sandblasting

The high-frequency sharp noise is reduced to below 500HZ, which greatly improves the noise environment;

(c) Simple and beautiful appearance:

Using color steel plate structure, the sandblasting room can be formed at one time, the appearance is simple and smooth, beautiful and durable.

There is also no need for surface treatment and decoration work;

(d) It is very convenient to move and retrofit: the modular design of the entire body of the sandblasting room,

Due to the characteristics of the color steel plate itself, it is light in weight, easy to cut, can be disassembled, and has no foundation.

So you can move and add or subtract units at will. This is especially suitable for disassembly, relocation and secondary use when necessary.

1.2. Working door, safety door and observation window

According to the process flow of the customer's workshop, a working door can be opened at one end of the house body. work gate

The opening method is manual folding.

Manual gate is W3.5*H3 meters. In addition, a W3.5*H3 meter working door (safety side door + observation window) is set on the side of the sandblasting room for the operator to unload the workpiece and enter the paint spraying room.

All door bodies are made of profiled steel as the skeleton, color steel plate as the door panel, and the inner side of the door panel is fixed with a protective rubber plate, so as to be firm and reliable, well sealed and open and close.

Observation windows are arranged on the door surfaces of the working door and the safety side door, so that the personnel outside the house can easily observe the sandblasting operation inside the house. At the same time, it is conducive to safe production and prevents accidents. In order to avoid damaging the window glass during sandblasting, we set up a protective plate inside the window glass. When the situation in the room needs to be observed, the protective plate is opened.

Lower the fender.

1.3. The protective layer of the wall is to effectively prevent the sand from being sprayed or rebounded on the wall and ceiling of the sandblasting room during the sandblasting (pellet) process, and a 4mm thick white rubber is attached around the inner wall of the room as a protective layer.

The rubber protective plates around the wall are pressed with a certain width of rubber plates on the steel skeleton of the house, and the adjacent rubber plates are arranged in a lap joint, which can effectively ensure that the color steel plate wall and the wall skeleton will not be damaged. Abraded by sand. When the wear-resistant rubber plate is damaged, it should be quickly replaced with a new wear-resistant rubber plate.

1.4, filter air inlet

There are labyrinth air inlets and even flow plates on both sides of the sandblasting room, so the sand material ejected during sandblasting operation will not splash to the outside of the sandblasting room through the air inlet, and the function of the even flow plate It is to distribute the air entering from the air inlet to the entire horizontal section of the sandblasting room, and then move it from top to bottom to make the flow rate of the horizontal section of the sandblasting room uniform.

1.5. Grille

The floor of the sandblasting room adopts metal grating, which is conducive to the collection and discharge of steel sand on the one hand, and the other

The surface is conducive to the safety of workers walking. In order to prevent large impurities and foreign objects from entering the sand return pipe through the honeycomb during working hours and blocking the spray gun, the equipment is equipped with a filter screen at the lower part of the grille (honeycomb floor) to prevent impurities and foreign objects from entering. It is very convenient to clean up impurities and foreign objects. It is only necessary to open the grille laid on the ground inside the house to clean it thoroughly, so as to ensure that the recycling pipe network can work smoothly for a long time.

The floor grille is welded by 40*4mm flat steel bars. The specific size and quantity are determined by the house body

The size and the rail spacing of the work trolley are determined. Generally, the floor grille inside the sandblasting room has a load-bearing capacity of less than 200kg per square meter. If a larger floor grille load-bearing requirement is required, the customer needs to put forward special design requirements.

1.6. Lighting device

Due to the high concentration of indoor dust during sandblasting operations, especially when the sandblasting abrasives used by customers are

When using abrasives with a high crushing rate such as quartz sand, the illumination in the room must be more guaranteed.

According to general specifications, the illumination in the sandblasting room must be ≥300LUX.

Considering that the splash of steel sand will cause damage to the lamps, a protective cover is designed, and 6 250W metal halide lamps are installed on the top of the room to ensure good lighting effects. In this scheme, metal halide lamps with a deep-illumination and anti-riot structure are used as lighting tools on the roof. The lighting of such lamps has the characteristics of strong ability to penetrate dust, and is especially suitable for use in the working conditions of large dust inside the room. . The roof also reserves a lamp maintenance channel, which is convenient for the replacement of protective glass and lamp maintenance.

2. Sandblasting system

The sandblasting system is one of the main working parts of the sandblasting room project. The configuration of the sandblasting equipment directly affects the production efficiency and sandblasting quality.

The sandblasting system consists of two parts: the pressure feeding sandblasting host part and the sandblasting worker protection system.

Company address : No. 33, Xinxing Road, Xinlian Community, Humen Town, Dongguan City

Company Tel: 0769-82261696 Mobile: 13215392671 (WeChat )

Company website: http://www.dgmagin.com