Products Center

Tel:+86-769-82261696

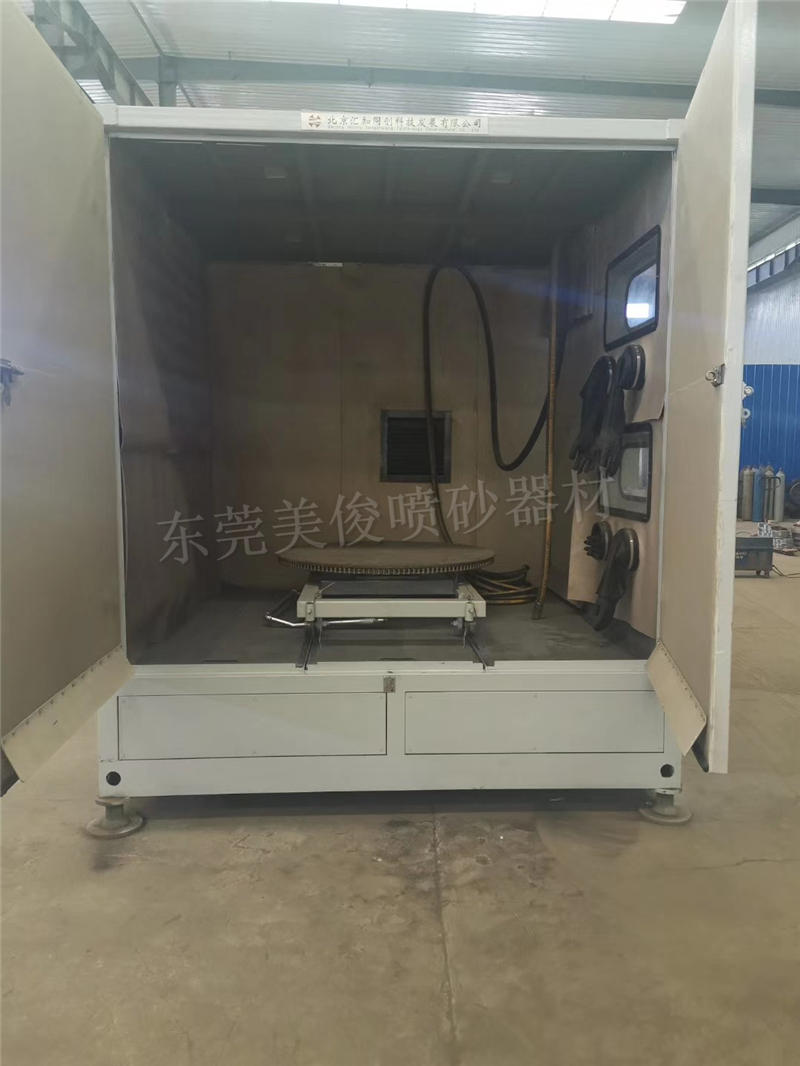

Dongguan Meijun Small Mobile Sandblasting Room Structure and Features:

1.spray Sand Room Body

The blasting room includes square frame + surface steel structure room body, working door, safety It is an ideal place for all-weather sandblasting and rust removal.

1.1 Light steel color plate structure sandblasting room

The sandblasting room adopts 50mm square tube as the basic frame, 25×40 square tube as internal support, and 2-3mm steel plate on the outside Welded, beautiful appearance, convenient installation, anti-corrosion and durable, the use of steel structure and steel plate structure to ensure its overall strength and Simple and beautiful appearance;

The house consists of four parts: loading platform, sandblasting cleaning room, unloading platform, self-propelled platform vehicle.

1.2 Work gate、Safety side doors and viewing windows

According to the process flow of the customer workshop, the two ends of the house are opened up and down door. The opening method of the working door uses the rolling shutter lifting method. The house body designed this time needs to set up working doors at both ends of the house body according to the customer's technological process.

A total of 1 set of rolling shutter doors, the size of the facade is 3.5X4 meters.

We use rolling shutters that are commonly used in the market. The inside of the life door will be protected with a rubber sheet.

On the facade of the working door and security side door of the house Observation windows are arranged on the top, so that the personnel outside the room can easily observe the sandblasting operation inside the room. At the same time, it is also conducive to safe production and prevents accidents. In order to avoid damaging the window glass during sandblasting, a protective plate is installed inside the window glass. When the situation in the sandblasting room needs to be observed, the protective plate is opened, and when the observation is completed, the protective plate is put down.

1.3 Wall protection layer

In order to effectively avoid sand spraying or rebounding to the wall and ceiling of the sandblasting room during the sandblasting (shot) process, The inner wall of the house and the ceiling are fixed with 3mm thick black rubber as a protective layer. The rubber protective plates around the wall are pressed with a certain width of rubber plates on the steel skeleton of the house, and the adjacent rubber plates are arranged in a lap joint, which can effectively ensure that the color steel plate wall and the wall skeleton will not be damaged. Abraded by sand. When the wear-resistant rubber plate is damaged, it should be quickly replaced with a new wear-resistant rubber plate.

1.7 Lighting Fixture

Due to the high concentration of indoor dust during sandblasting, especially when the sandblasting abrasive used by the customer is an abrasive with a high crushing rate such as quartz sand, the illumination in the room should be more appropriate. guarantee. According to the general specification, the illumination in the sandblasting room must be ≥120LUX. TestConsidering that the splash of steel sand will cause damage to the lamps, it is designed to place the lamps on the top, and illuminate the room through the tempered glass, and install 2 rows of 4-6 250-watt metal halide lamps on the top of the room to ensure good lighting effects. In this scheme, metal halide lamps with deep-illumination and anti-riot structure are used as lighting tools on the roof. The lighting of such lamps has the characteristics of strong ability to penetrate dust, and is especially suitable for use in the working conditions with large dust inside the house. There is also a special reserved lamp inspection channel on the roof, which is convenient for the replacement of protective glass and lamp inspection.

2. Sandblasting and protective equipment

The sandblasting system is one of the main working parts of the sandblasting room project. The configuration of the sandblasting equipment directly affects the production efficiency and Sandblasting quality.

The blasting system consists of two parts: the pressure-feed blasting host part and the blasting worker protection system.

2.1 Blast host:This set of sandblasting room uses a pressurized sandblasting machine as the core unit of the sandblasting system, equipment model: CS-1m³. The machine is equipped with 1 set of high-efficiency spraying and grabbing, which is a mature technology imported from Japan's Houji Engineering Co., Ltd., and its characteristics are: A. Compact structure and large sand storage capacity.

B. Safe, reliable and easy to maintain.

C. Mature and stable equipment, less wearing parts

2.1.1 Main technical parameters:

Bore size: 800mm

Cylinder height: 1500mm

volume: 1m3

Amount of sand: 1500Kg (steel shot abrasive) / 800Kg (brown corundum)

Working pressure:0.5-0.8Mpa

Work efficiency:≥15m2/h/single grab

Compressed air consumption: >6.1m3/min/support

2.1.2 CS- Main structure of 1m³ sandblasting machine:

This machine consists of sandblasting tank, remote control device, sandblasting valve, Sandblasting pipe, air supply pipe, blasting grab, filter, etc.

2.1.2.1Sandblasting Can body

CS sandblasting room series projects are equipped with pressurized tanks: our standard preparation .

2.1.2.2Remote control

The remote control is a remote pneumatic foot switch. You can control the sandblasting switch at any time during the sandblasting operation. It is easy to start and stop the sandblasting operation. The remote control device is easy to operate, reliable, stable and responsive.

2.1.2.3 Air Control Sand Valve

The manual sand valve is an important part of the sandblasting machine. Its main function is to control the opening and closing of the sand, and to adjust the sand flow steplessly during sandblasting. The quality of the sand valve directly affects the Whether the sandblasting machine can work normally, this type of sandblasting machine is equipped with a special sand valve for the house body sandblasting machine independently developed and produced by our company. It has the characteristics of reliable quality, convenient adjustment and simple maintenance. Structure; the sand valve consists of three parts: sand valve body, three-way sand pipe, sand control valve.

The sand valve body is equipped with a rubber core, which is in the shape of a rubber tube and is made of polyurethane, nylon, wear-resistant rubber, etc. The two roller shafts translate under the action of the adjusting bolt and the ejector rod, and the rubber core is squeezed to deform, thereby opening and closing Sand valve; p>

The three-way sand pipe mainly acts as a channel connecting each interface and abrasive and compressed air;

The sand control valve mainly plays a control role. The inner cavity is equipped with a compression spring to move the top rod to close the sand valve; the control air source enters from the inlet, and the bowl-shaped The diaphragm (large rubber pad) drives the ejector rod, overcomes the spring force, the sand valve opens, controls the air source to discharge, and the sand valve returns to its original state under the action of the spring force. The handwheel can adjust the opening.

Features:

A.

B. Easy to adjust and maintain;

C. Sand evenly

D. Less consumables

In addition, there is a shut-off valve between the sandblasting tank and the sand valve, mainly for the purpose of Equipment maintenance is convenient: when the sand valve is blocked or the accessories need to be replaced, the shut-off valve can be closed to avoid all the sand in the sandblasting tank being released during maintenance.

2.1.2.4Sandblasting Tube:Using the best explosion-proof and wear-resistant sandblasting special tube in China

its model: φ50(outer diameter)*32(inner diameter)*9m(standard length) or φ40(outer diameter)*25(inner diameter)*9m(standard length) quantity: 1 piece

Lifetime: ≥800h(One end of the blasting pipe is equipped with a flexible and convenient quick connector, and the other end is equipped with a nozzle connector)

2.1.2.6Blasting with Venturi sandblasting tip:

Sandblasting grab me The high-speed sandblasting machine produced by the company has a venturi-shaped nozzle. When the air flow enters the contraction section of the high-speed sandblasting machine, the air flow begins to accelerate until the speed of sound; when it reaches the straight section of the venturi, the air flow rate is stable at At the speed of sound, when the airflow reaches the expansion section of the venturi, the airflow continues to accelerate to supersonic speed; in the expansion section of the venturi there are secondary air supplementary holes distributed circumferentially, so in the supersonic stage, the airflow expands rapidly, and the nozzle starts from the secondary The supplementary air hole sucks in a large amount of auxiliary air to further accelerate the sand material; compared with the ordinary sand blasting gun, the sand blasting speed of this sand blasting gun is faster, and the recoil force is small, which saves the operation timeForce; the shrinking section, straight section and expansion section of this type of high-speed sandblasting are all made of boron carbide, and the working life is long. Generally, a high-speed sandblasting can be used for 800-1000 hours .main features: