Products Center

Tel:+86-769-82261696

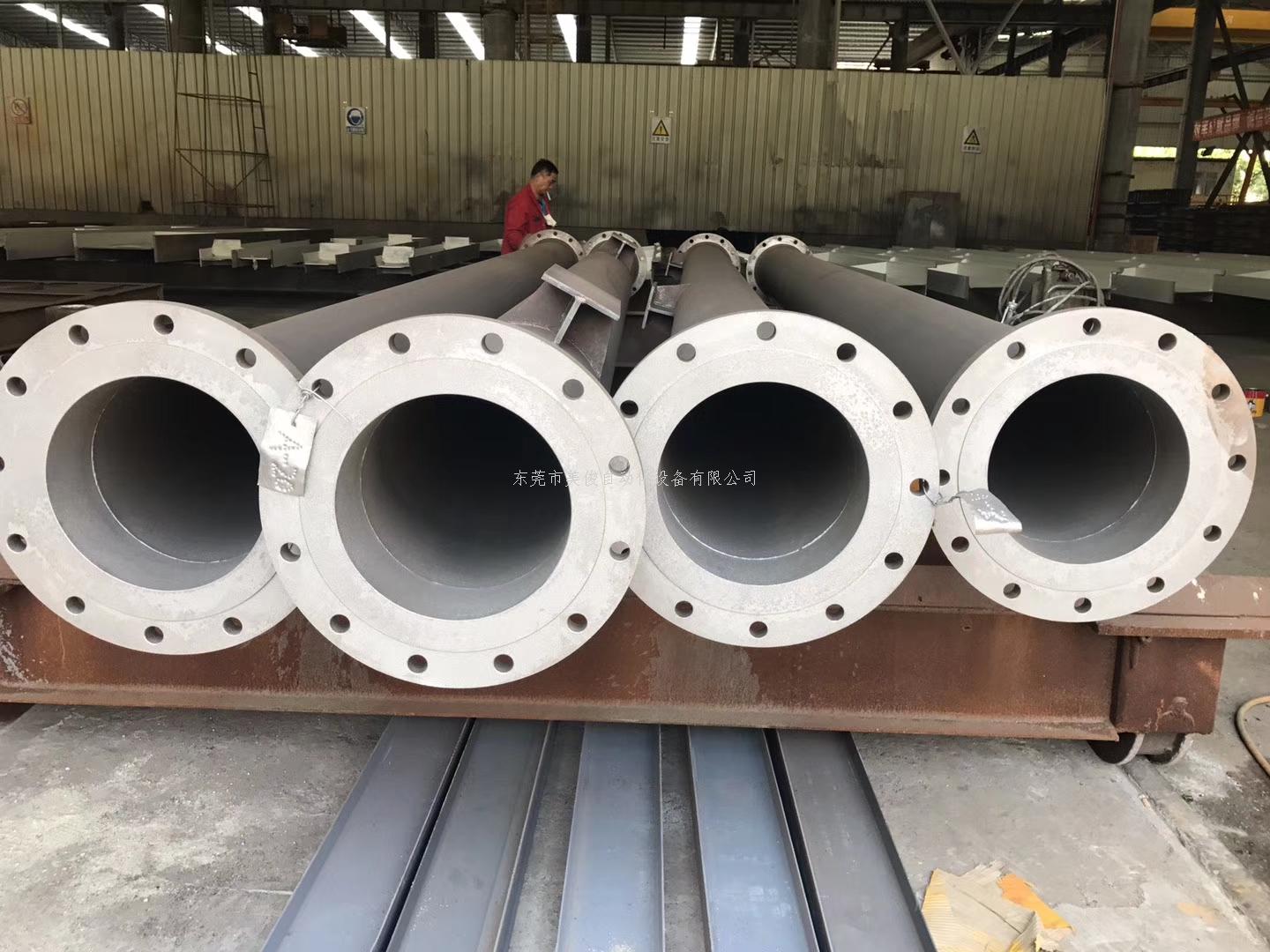

pipe blasting gun, pipe blasting machine, pipe blasting, blasting blaster, blasting gun , Inner wall blasting machine, pipe blasting gun, pipe blasting machine,

Model:MJ50-300MM

● Blast gun for the inner wall of the pipe

TubeBlast gun for the inner wall of the channelMainly used for the inner wall of small pipes sandblasting, because the duct is narrow, the normal forward jet single inlet and

The double-inlet sandblasting gun cannot change the direction in the pipeline, so it cannot blast the inner wall of the pipeline, which requires forward spraying. Abrasive

It is necessary to change the angle and direction to achieve the purpose of sandblasting the inner wall of the pipe, Inner wall sandblasting gunIt came into being in this situation.

Blast gun for the inner wall of the pipe From the sandblasting mode:

There are sand head type inner wall guns and rotating inner wall guns, in general, the diameter of the pipe300MMThe following mode with sand head,300MMwith

Use the rotating head mode.

Blast gun for the inner wall of the pipe In terms of materials: there are cemented carbide tungsten steel and boron carbide.

Dongguan Humen Meijun Sandblasting Equipment the inner wall of the pipe Sandblasting gun, according to the different abrasives used by customers, flexible application can be targeted Sexual Materials

and layout, the main purpose is to improve the service life of spare parts under different conditions.

●2020 MJ50-300MM inner wall sandblaster improved features:

1) The sand head is changed to hot-pressed pure boron carbide and tungsten carbide. For different abrasives, different material nozzles are used, which increases the wear time and also increased lifespan;

2) The distance of the sanding head can be adjusted flexibly, so that can use different coarse and fine abrasive grains, At the same time, after the distance is changed, the angle of the abrasive impact will change, and the impact speed and strength of the abrasive will also change correspondingly, which can adjust the cleaning uniformity and roughness of the inner wall of the pipeline;

3) The inclined surface of the sand-scattering head is changed from a conical plane to a slightly concave arc, which is more in line with the airflow direction, reduces the impact angle of the sand particles on the sand-scattering head, and reduces the wear intensity. Makes the grit smoother.

pipe blasting gun, inner wall sandblaster, inner hole blasting gun, pipe inner wall blasting machine

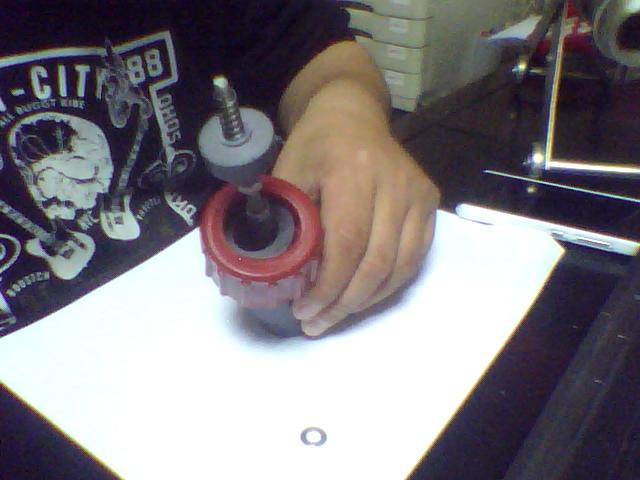

Internal component installation method:

Step 1: Install the screw and the sand separator first, insert the screw into the sand separator, and tighten both ends with nuts.

Step 2: Install a screw sheath (small oblong tube), then install a nut, then install a screw sheath, and then a nut;

Step 3: Install the large nozzle in the direction, the end with the bell mouth is facing the sand separator;

Step 4: Put the red spray gun screw cap on.

Step 5: The last nut---the last sand head---add a gasket---up the spring-add a gasket (optional)-- on the nut.

Step 6: Put the whole assembly into the gun body from the front, and screw the red spray gun screw cover (the polyurethane cover needs to be glued with water tape or glued firmly, and the steel sleeve can be tightened) ), the assembly is complete.

Step 7: According to the size of the sandblasting pipe and the required sandblasting intensity, adjust the distance between the sand blasting head and the spray gun mouth, if it is close to the spray gun mouth

The larger the sand reflection angle, the larger the jet pipe, the longer the sand grain reflection angle, the smaller the jet pipe is. Smaller, less powerful.

Company name: Magin Dongguan Humen Meijun Sandblasting Equipment Store

Address: No. 33, Xinxing Road, Xinlian Community, Humen Town, Dongguan City

Phone: 0769-82261696 Phone: 13215392671

http://www.dgmagin.com

elsonzhong@163.com QQ:491440166