Products Center

Tel:+86-769-82261696

Meijun's boron carbide nozzle is very hard One of the artificial materials, it has the characteristics of light weight, semiconductor physical properties, absorption of neutrons, high grinding efficiency, and no reaction with strong acids and alkalis.

The Mohs hardness is 9,36, the microhardness is 5400-6300 kilograms per square meter, the density is 2.52 kilograms per square meter, and the melting point is 2450 degrees Celsius.

Therefore, boron carbide is an ideal nozzle material medium for sandblasting, powder spraying, high-pressure water cleaning, oil spraying, spraying, slurry spraying, fire spraying and other industries that require wear resistance, pressure resistance, and high temperature resistance.

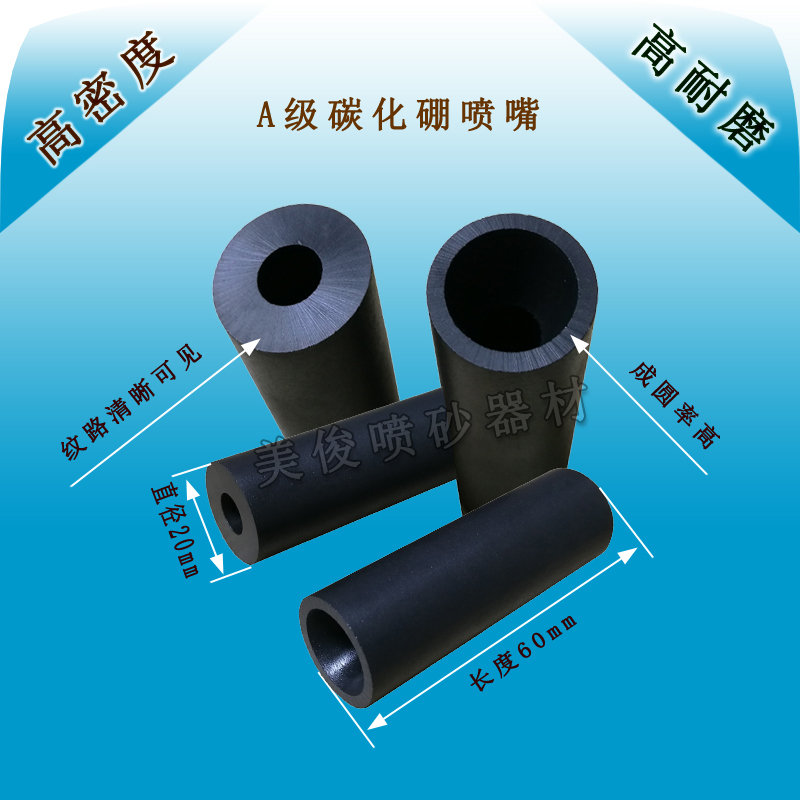

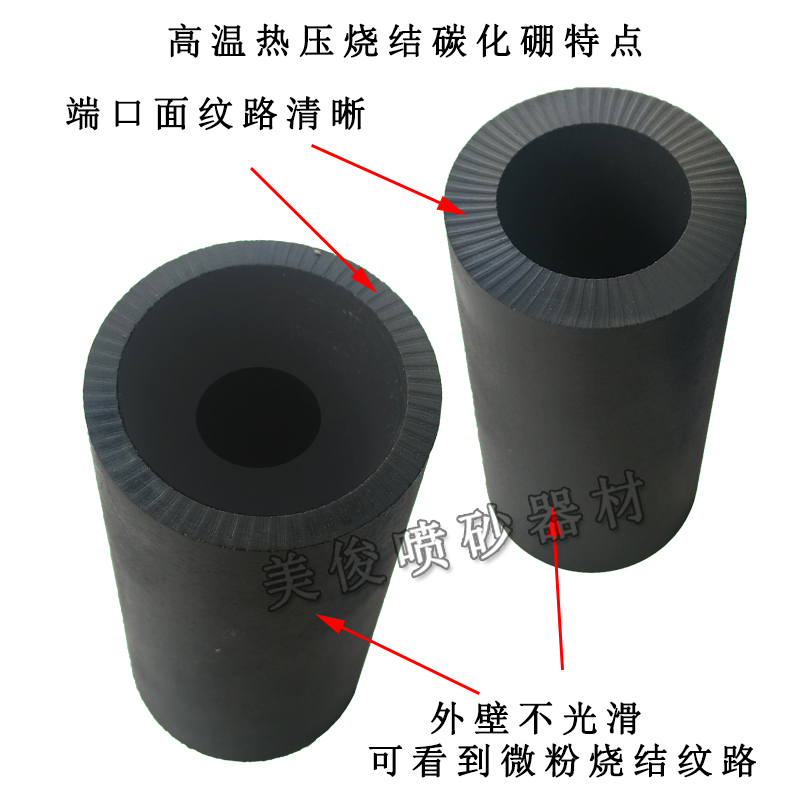

Boron carbide nozzles are made of boron carbide as the main ultra-fine powder, sintered by high temperature hot pressing process, polished and cut to form The standard specific model of sandblasting nozzle. It has high temperature resistance, wear resistance, corrosion resistance, light specific gravity, high hardness, and the hardness is second only to diamond. The bending strength is 40kg/cm2, and the physical and mechanical properties of the boron carbide nozzle are: hardness HRA 92-94. Compressive strength 240kg/cm2, The density is 2.45-2.5, and the service life is 3 times that of ordinary cold-pressed sintered cemented carbide (tungsten carbide) and silicon carbide.

Boron carbide nozzle sandblasting nozzle sandblasting nozzle

Buyers should understand more clearly in the process of selecting boron carbide nozzles. The nozzle material, sintering method, density, hardness and bending strength determine the service life of the nozzle. Long service life and high cleaning efficiency of sandblasting work, the cleaning cost is reduced, and the enthusiasm of sandblasting operators can be fully exerted. Worn nozzles lead to frequent replacement and loss of a lot of production time, the effect of efficient sandblasting equipment will be greatly reduced, work efficiency is not high, cleaning costs will rise, and the enthusiasm of sandblasting workers will be frustrated.

So it is very important to choose a high wear-resistant hot-pressed sintered pure boron carbide nozzle, choose Dongguan Meijun Sandblasting Equipment Co., Ltd. High-density pure carbonization Boron nozzles are even more important to ensure your longevity and blasting efficiency!

Boron carbide nozzle specifications: unit (MM)

Regular stock specifications:

Outer Diameter 20MM Series: Inner DiameterΦ(1.05-12)*Outer Diameter 20MM*Length 35/45/50/60/80/82MM

Outer Diameter 15MM Series: Inner DiameterΦ(1.05-10)*Outer

Diameter 15/16MM*Length 35/40/55MM

Outer Diameter 28MM Series: Inner DiameterΦ10/12/14mm*Outer Diameter 28MM*Length 75/80M Boron carbide nozzles, sandblasting nozzles, nozzles, wear-resistant sandblasting nozzles

Meijun's other specifications of sandblasting nozzles can be customized according to drawings and samples!

Dongguan Humen Meijun Sandblasting Equipment

Address: Qihe Industrial Park, No. 33 Xinxing Road, Xinlian

Community, Humen Town, Dongguan City

Tel: 0769-82261696 13215392671(WeChat) Mr. Zhong

Website http://www.dgmagin.com