Products Center

Tel:+86-769-82261696

Dongguan Meijun specializes in sandblasting room dust removal machine accessories, dry dust collector accessories including electromagnetic pulse valve, dust removal bag, pulse controller, air control components, etc.

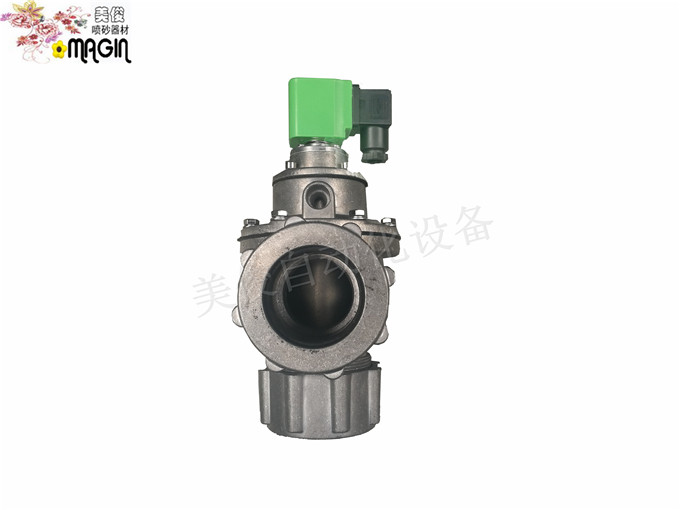

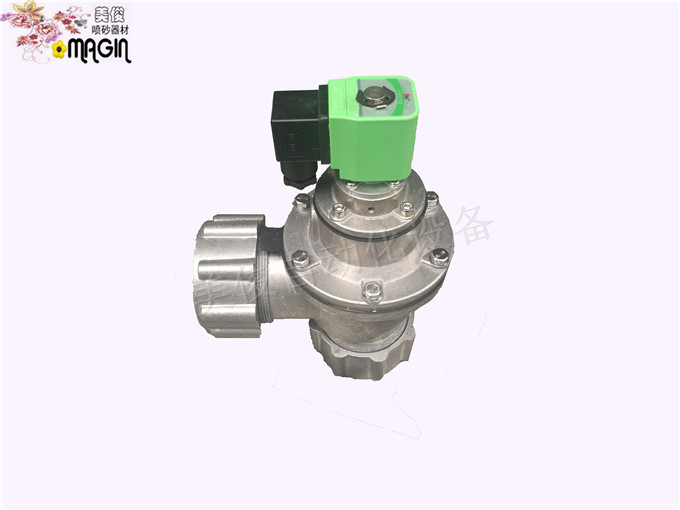

The electromagnetic pulse valve is specially designed for the application of dust removal equipment. It is a valve with high flow rate, long life and instant switch. It is controlled by electromagnetic pilot to open and close. Due to the advanced design, the valve has good fluidity. The rubber diaphragm has low pressure loss, which ensures the rapid opening of the electromagnetic pulse valve when it receives the pulse electrical signal and the rapid closing after the completion of the pulse.

High-purity aluminum alloy die-casting valve body, electromagnetic pulse valve diaphragm composed of top special clips, making the diaphragm have extremely high tensile strength, anti-aging and low wear, making the MAGIN electromagnetic valve The injection life of the pulse valve is higher than 1 million times or three to five years without damage.

The electromagnetic pulse valve coil is made of insulation injection higher than the national standard, and the protection level is P65 full potting, all copper enameled wire, and the number of turns is higher than the national standard to ensure that the electromagnetic pulse valve is energized for 6 million times without damage. The coil can be rotated 360" on the pulse spool, and the junction box can be installed with a 4 x 900 rotation, which can prevent rainwater from entering when exposed to the open air, which greatly facilitates installation at different angles.

product description

MG-DMF-ZJ electromagnetic pulse valve, the angle between the input port and the output port of the MG-DMF-ZJ valve is 90°, which is called a right-angle valve. The short pipe or blowing pipe on the ) is directly inserted into the conical sealing rings of the input and output ports of the valve, and the compression nut is tightened. It is easy to install and has smooth air flow. It can provide ideal cleaning air pulses, suitable for various filter units. of ashes.

MG-DMF-ZJ type electromagnetic pulse valve input port and an output port angle is 90 DEG angle valve, the input and output for external thread, and is equipped with a pressing nut, gas tank (gas) on spools or blowing Z directly inserted in the valve of the input and output of conical sealing ring and tighten nut, convenient installation, smooth airflow, provides an ideal cleaning Qimai,applicable to all kinds of filter element cleaning.

Use technical indicators

|

Operating pressure |

0.2~0.6MPa |

|

Working medium |

Clean air |

|

Voltage Voltage |

DC24V AC110V AC220V(±10%) |

|

Current |

1A 0.46A 0.23A |

|

Temperature level |

1. Normal temperature -25℃~80℃(-13℉~176℉) 2. High temperature -25℃~230℃(-13℉~446℉) |

|

Relative humidity of air |

The relative humidity of the air is less than or equal to 85% |

|

Degree of protection |

IP65 |

|

Diaphragm life |

Above 1 million times, or 3-5 years |

Material Description

|

Body |

ADC12Aluminum ADC12 aluminum alloy |

|

Clamp spring |

304 stainless steel 304stainless steel |

|

Pilot component |

430FR stainless steel 430FR stainless steel,etc |

|

Diaphragm |

Nitrite rubber/fluororubber(high-temperature valve) |

|

spring |

304 Stainless Steel 304 stainless steel |

|

Fastener Fastener |

302 Stainless Steel 302 stainless steel |

The diaphragm is made of top-grade finished diaphragms, the quality is comparable to that of imported ones, and it has super stretchability. Each diaphragm is strictly inspected before it can enter the assembly line. After assembly, each finished valve is inspected. All indicators are all Qualified before leaving the factory.

Diaphragm with the top end of the film, the quality and import comparable, super tensile, each piece of the film are strictly detected before entering the assembly line, the assembly after each finished product valve testing, the indicators are all qualified before the factory

Installation method tips

1. The air source for the electromagnetic pulse valve is provided by the air box (air bag). There are two types of air distribution boxes: square and round. When the electromagnetic pulse valve is used, the installation of the square air distribution box is more convenient.

2. The cross-sectional area and length of the gas distribution box determine the gas storage volume, and its volume should meet the requirements of each pulse valve of the group.After the first injection, the residual pressure in the box should not be lower than 50% of the pressure before the injection. The inner diameter of the intake pipe determines the inflation rate to the air distribution box. Return to pre-blow pressure.

3. The pulse valve should be installed on the top or side of the gas distribution box. When installing the side, the center of the input end of the pulse valve should not be lower than the center line of the side of the gas distribution box. The pulse valve should not be installed at the bottom of the gas distribution box. , and the output end of the pulse valve should be installed in a horizontal or downward position, and cannot be installed in an upward position.

4. The blowing hole of the blowing pipe should be less than 18 or so, the opening is: 8-32mm (far small and near large), and the blowing pipe should be 200-400 meters away from the mouth of the cloth bag.

Electromagnetic pulse valve FAQ

|

Use Phase |

Symptoms |

Cause Analysis |

Exclusion method |

|

Installation and debugging |

All valves cannot be opened, but the pilot part |

Check if the air bag pressure is too low |

Troubleshooting Air Leaks |

|

Some valves are not working, others are OK |

Check valve wiring and coils |

Replacement Accessories |

|

|

All valves cannot be closed, there is air leakage, |

The air inlet of the valve is installed opposite to the injection port |

Reinstall |

|

|

Some valves cannot be closed and there is air leakage |

Impurities are adsorbed on the diaphragm, and the moving iron core is stuck |

Clean the diaphragm, check the integrity of the diaphragm, |

|

|

During use |

Valve closes slowly |

Diaphragm orifice is blocked |

Clear the diaphragm orifice |

|

Some valves are leaking, and the diaphragm cannot be closed, |

Impurities are adsorbed on the diaphragm, the pilot is damaged, and the moving iron core is stuck |

Clean the diaphragm, check the integrity of the diaphragm, |

|

|

The coil heats up and burns out |

Power on for a long time |

Check the working condition of the control system |

|

|

There is voltage, but the valve does not operate |

Diaphragm damaged or orifice blocked |

Timely replacement of accessories |

|

|

The ambient temperature is low, the valve is leaking or cannot be opened |

The ambient temperature is too low, and there is ice in the valve |

Pay attention to heat preservation |