Products Center

Tel:+86-769-82261696

Dongguan Meijun sandblasting equipment professional surface treatment sandblasting processing: hardware derusting, aluminum alloy sandblasting, glass sandblasting (matte effect), plastic sandblasting (deburring), acrylic sandblasting (matte effect), PC, PS surface treatment, resin surface treatment, digital product shell surface treatment, casting workpiece sandblasting, zinc alloy sandblasting (rough surface), stainless steel (large workpiece) material sandblasting, stone sandblasting engraving, hardware removal paint, hardware removal Welding scars, shot blasting, crystal spray patterns, decorative sandblasting engraving, etc.

Meijun sandblasting machine is suitable for sandblasting of metal products, sandblasting of plastic products, sandblasting of resin products, sandblasting of precious metal ceramics, sandblasting of wood products, sandblasting of glass related products

One: The main application range of sandblasting

(1) The coating of the workpiece and the sandblasting before the workpiece bonding can remove all dirt such as rust on the surface of the workpiece, and establish a very important basic schema (the so-called rough surface) on the surface of the workpiece, and can By exchanging abrasives with different particle sizes, for example, the abrasives of Feizhan abrasives can achieve different degrees of roughness, which greatly improves the bonding force between the workpiece and the paint and plating. Or make the bonding parts more firm and better in quality.

(2) Cleaning and polishing of rough surfaces of castings and workpieces after heat treatment Sandblasting can clean all contaminants (such as oxide scale, oil and other residues) on the surfaces of castings and forgings and workpieces after heat treatment, and polish the surface of workpieces to improve the smoothness of workpieces , can make the workpiece reveal a uniform and consistent metal color, so that the appearance of the workpiece is more beautiful and good-looking.

(3) Burr cleaning and surface beautification of machined parts Sandblasting can clean the tiny burrs on the surface of the workpiece, make the surface of the workpiece more flat, eliminate the harm of burrs, and improve the grade of the workpiece. And sandblasting can make small rounded corners at the junction of the workpiece surface, making the workpiece more beautiful and more precise.

(4) Improve the mechanical properties of the parts. After sandblasting, the mechanical parts can produce uniform and fine uneven surfaces on the surface of the parts, so that the lubricating oil can be stored, thereby improving the lubrication conditions, reducing noise and improving the service life of the machine.

(5) Lighting effect For some special-purpose workpieces, sandblasting can achieve different reflections or matts at will. Such as the grinding of stainless steel workpieces and plastics, the polishing of jade articles, the mattization of the surface of wooden furniture, the pattern of frosted glass surfaces, and the textured processing of cloth surfaces.

Rice cooker non-stick coating pretreatment - increase surface roughness;

Surface cleaning of stainless steel and chrome-plated products - matte effect;

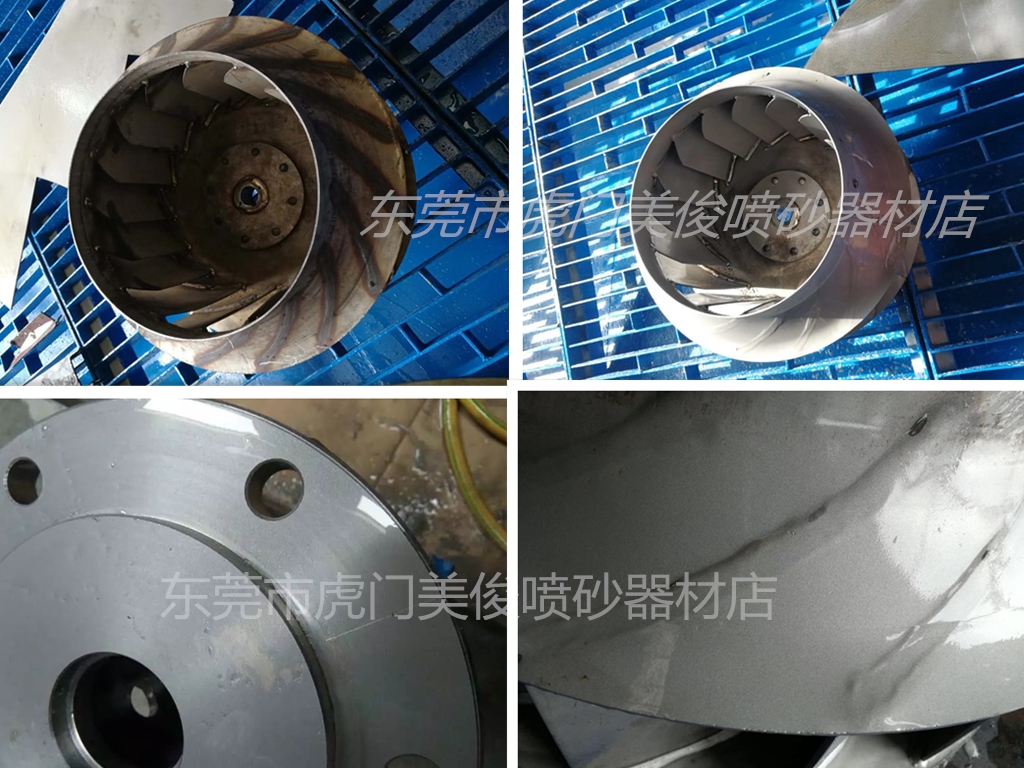

Stainless steel welding scar process water blast cleaning case;

Two: sandblasting raw materials

Sandblasting: Technical term for gold and silver coin minting. That is, on the production mold of gold and silver coins, metal sand particles of various sizes and types are used to spray the pattern part into a very fine frosted surface. Layering. Refined Quartz Sand

Sandblasting (referring to metal surface rust removal or plating on metal surface) quartz sand, ordinary quartz sand, refined quartz sand: high hardness, good rust removal effect, physical and chemical indicators are as follows. SiO2≥88—99.8% Fe2O3≤0.1—0.005% , Refractoriness 1450---1800 ℃, the appearance of particles is uniform, the commonly used particle size is 1-3MM and 0.1-0.3MM, pure white. The particle size range is mostly 5-220 mesh, which can be produced according to user requirements. Main uses: metallurgy, ink silicon carbide, glass and glass products, enamel, cast steel, water filtration, caustic soda, chemical industry, sandblasting and other industries.

Sand Material: emery, glass beads, glass sand, resin sand, plastic pellets, stainless steel beads, steel beads, aluminum beads, walnut sand, white corundum, alumina, etc.

Sandblasting equipment and equipment: water sandblasting machine, automatic sandblasting machine, pass-through sandblasting machine, polishing sandblasting machine, manual sandblasting machine, pressure sandblasting machine, etc. Different sandblasting equipment handles workpieces of different sizes , or the surface roughness, color and texture are all different.

Three: Sandblasting process stage

The sandblasting process uses compressed air as the power to form a high-speed jet beam, and sprays the material and other high-speed jets to the surface of the workpiece to be treated, so that the appearance of the outer surface of the workpiece changes. A certain degree of cleanliness and different roughness improve the mechanical properties of the workpiece surface.

Four: pre-treatment stage of sandblasting process

The pretreatment stage of the sandblasting process refers to the treatment that should be carried out on the surface of the workpiece before the workpiece is sprayed and sprayed with a protective layer. The quality of the pre-treatment of the sandblasting process affects the adhesion, appearance, moisture resistance and corrosion resistance of the coating. If the pretreatment work is not done well, the rust will continue to spread under the coating, causing the coating to fall off in pieces. The surface that has been carefully cleaned and the workpiece that is generally cleaned simply can be compared with the coating by exposure method, and the lifespan can be 4-5 times different. There are many methods of surface cleaning, but the most commonly accepted methods are: solvent cleaning, pickling, hand tools, power tools.

Dongguan Meijun Sandblasting Equipment undertakes sandblasting of various workpieces, and does it in accordance with customer demand standards! ! !