Engraving sandblasting machine

The principle of sandblasting engraving is to use high-pressure air ejected from a nozzle with a diameter of 3-10 mm to drive the abrasive (including brown corundum, white corundum, steel sand, etc. with water chestnuts) to impact the surface of stone or glass at high speed, thereby Hollow out the sprayed object to achieve the purpose of carving.

The operation process of sandblasting engraving:

Use computer typesetting CAD, photoshop and other plane processing software to engrave the pattern, text, LOGO and other content that needs to be engraved on the self-adhesive paper (sandblasting protective film) through the computer engraving and cutting machine, just like advertising in a roadside advertising store The words in the advertising store are only for words, and the unnecessary parts are removed and the words are left, while sandblasting engraving is just the opposite. The words you want to engrave, control the sandblasting gun to blast engraving on the hollow part.

When the high-pressure air drives the emery to hit this part, the effect is like tens of thousands of chisels with a size of -96 grains hit this part. If you hit it hard, the part that needs to be engraved will be removed to form text or patterns. To the place protected by the film, because the film is soft, the hard one will bounce out when it touches the soft one, and the objects under the protective film will remain intact.

The depth of engraving is determined according to the processing requirements, and the length of time the spray gun stays in determines the depth of engraving. If you want to carve deeper, just spray more on the place where you need to carve deeply, that's all, this technique is not difficult, usually a normal person can do it in a few minutes, without any foundation, the content of the engraving is the same as what is outputted in the computer The same, neat and beautiful, not deformed, not out of shape.

The cost of engraving is low. Generally, the cost of engraving materials for one square meter, including protective film, electricity, and emery, is about 12-20 yuan.

The engraving speed is fast. For example, it only takes a few seconds to engrave a character that is 3 cm large and 2 mm deep. This is incomparable to traditional manual and other CNC tool engraving.

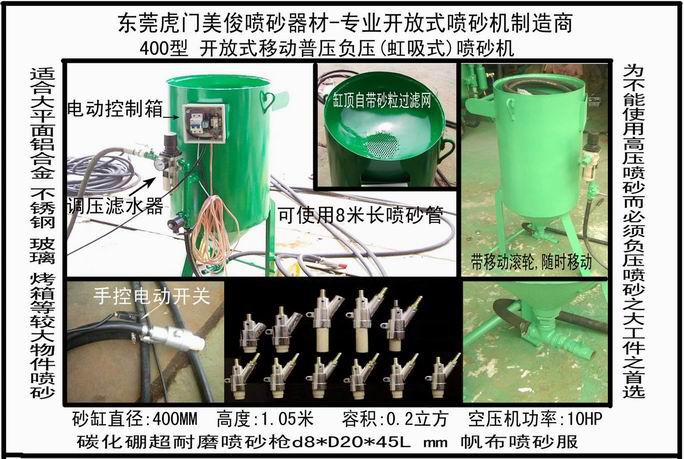

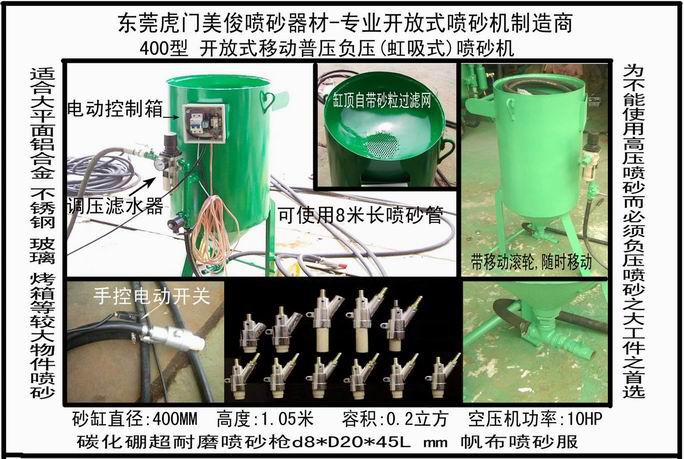

Sandblasting stone engraving machine currently has several models of high-pressure mobile open type, high-pressure recycling type, siphon type fixed box type, and suction mobile recycling type. Users should choose according to their own needs and processing requirements, which are economical and affordable. The most efficient is the pressure mobile sandblasting machine (open type), such as the 400-type pressure engraving sandblasting machine produced by our company, which uses a 5-6 cm high wear-resistant boron carbide nozzle and an inner diameter of 13-19mm. Textured surface high pressure wear-resistant sandblasting machine can be equipped with pneumatic control type or electric control type according to the requirements of the operating environment. It is easy to use and economical. Welcome to consult!

Company Name: Magin Dongguan Humen Meijun Sandblasting Equipment Store Telephone:0769-82261696 13215392671