Products Center

Tel:+86-769-82261696

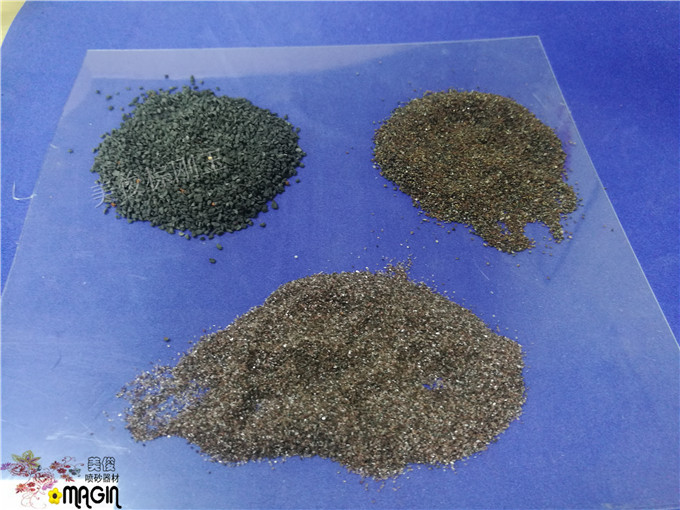

Dongguan Meijun Brown Corundum:

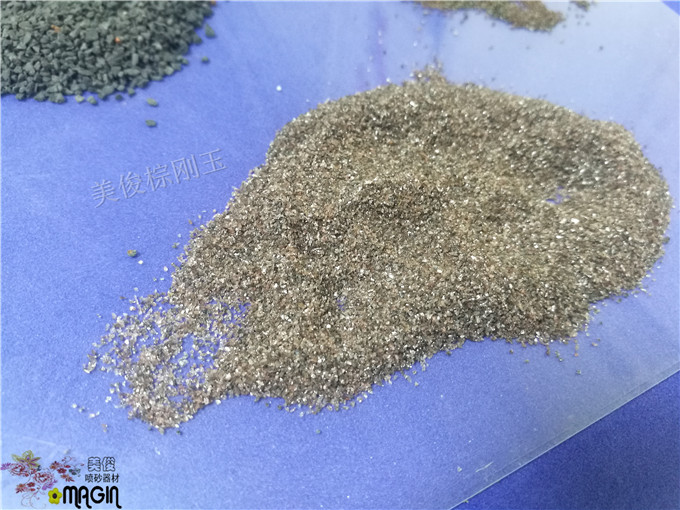

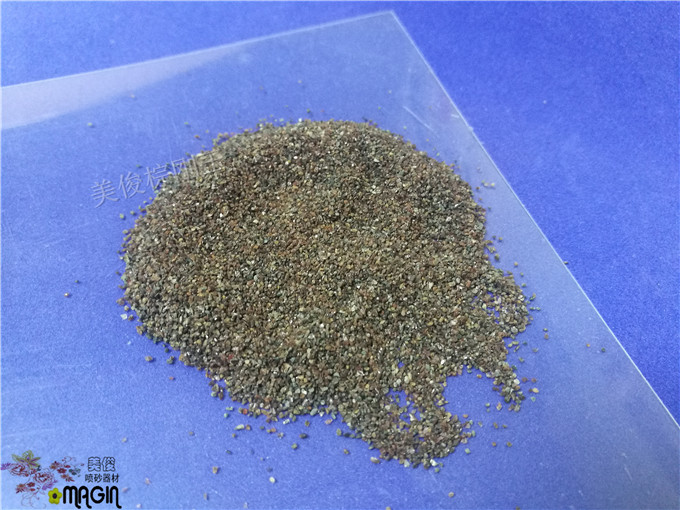

No. 16 No. 24 No. 36 No. 46 No. 60 No. 80 No. 100 No. 120 No. 150 No. 180 No. 200 No. 220 No. 280

The brown corundum we sell has a complete range of grades and meshes. It has been tried by many glass deep processing, optoelectronic enterprises, solar energy industry (polysilicon sandblasting, monocrystalline silicon sandblasting), and hardware factories. The surface treatment effect is obvious and the price is high. Welcome to consult!

The common name of brown corundum, also known as emery, is a brown artificial corundum obtained by melting and reducing three raw materials of bauxite, carbon material and iron filings in an electric furnace, so it is brown corundum.

The main chemical composition of brown corundum is AL2O3, its content is between 94.5% and 97%, and it also contains a small amount of Fe, Si, Ti and so on.

Brown corundum is one of the basic abrasives because of its high hardness and good toughness. Its main functions are as follows

(1) Due to its high temperature resistance, corrosion resistance, high strength and other properties, cast steel sliding nozzles are used to control the lining (wall and pipe) of rare and precious metals, special alloys, ceramics, and iron-making blast furnaces; physical and chemical utensils, spark plugs, Heat resistant and oxidation resistant coating.

(2) Due to the characteristics of high hardness, good wear resistance and high strength, in the chemical system, it is used as various reaction vessels and pipelines, parts of chemical pumps; as mechanical parts, various molds, such as wire drawing dies, Extruding pencil core die mouth, etc.; making knives, die abrasives, bulletproof materials, human joints, sealing die rings, etc.

(3) Corundum insulation materials, such as corundum light bricks, corundum hollow balls and fiber products, are widely used in furnace walls and furnace tops of various high-temperature furnaces, which are both high temperature resistant and thermal insulation.

Brown corundum grain size sand is made by manual screening of brown corundum blocks and processed by counter-roller, ball mill, Barmac and other equipment. The grain size is F8-F325. It is mainly used for polishing, grinding, industrial grinding, etc. It is required to be processed by water washing, pickling treatment and other methods, which can meet the different needs of customers.